The 05 International 4200 brake pressure warning is a common issue that many truck drivers encounter. This warning light indicates a problem with your truck’s braking system, which can be a serious safety concern. If you see this warning light on your dashboard, it’s crucial to understand the possible causes and address the issue promptly.

This article will guide you through the common causes of the 05 International 4200 brake pressure warning, troubleshooting steps, and solutions to get your truck back on the road safely. We’ll also provide valuable insights from a seasoned expert in the field.

Understanding the 05 International 4200 Brake Pressure Warning

The 05 International 4200 brake pressure warning light illuminates on your dashboard when the electronic braking system (EBS) detects a problem with the brake pressure. This could indicate various issues, ranging from a minor leak to a major system malfunction.

Here’s what you need to know about this warning:

- Safety First: The 05 International 4200 brake pressure warning is a serious indicator, signaling potential braking system failure.

- Immediate Attention: Never ignore this warning light. Pulling over to a safe location and inspecting your brakes is crucial.

- Multiple Causes: The warning can stem from several factors, requiring thorough troubleshooting.

Common Causes of the 05 International 4200 Brake Pressure Warning

Understanding the common causes of the brake pressure warning is the first step in effectively troubleshooting the issue. These include:

1. Low Brake Fluid Level: This is the most common cause. The brake fluid acts as the hydraulic medium transmitting pressure to the brakes. Low fluid levels can lead to reduced brake pressure and trigger the warning light.

2. Air in the Brake Lines: Air in the brake lines can compress, reducing the braking force. This can be caused by a leak, a faulty brake master cylinder, or improper bleeding procedures.

3. Leaking Brake Components: Leaks in the brake lines, calipers, wheel cylinders, or master cylinder can cause a loss of brake fluid, reducing pressure and triggering the warning.

4. Faulty Brake Master Cylinder: The brake master cylinder is the heart of the hydraulic braking system. A faulty master cylinder can fail to pump sufficient fluid, leading to low brake pressure and triggering the warning.

5. Defective Brake Booster: The brake booster assists the driver in applying brake pressure. A defective booster can result in a weakened braking system, causing a loss of pressure and triggering the warning.

6. Electrical Malfunction: Sometimes, the 05 International 4200 brake pressure warning can be triggered by an electrical malfunction in the EBS system. This could include a faulty sensor, wiring problem, or a malfunctioning EBS control unit.

Troubleshooting the 05 International 4200 Brake Pressure Warning

Diagnosing the issue behind the 05 International 4200 brake pressure warning requires a systematic approach:

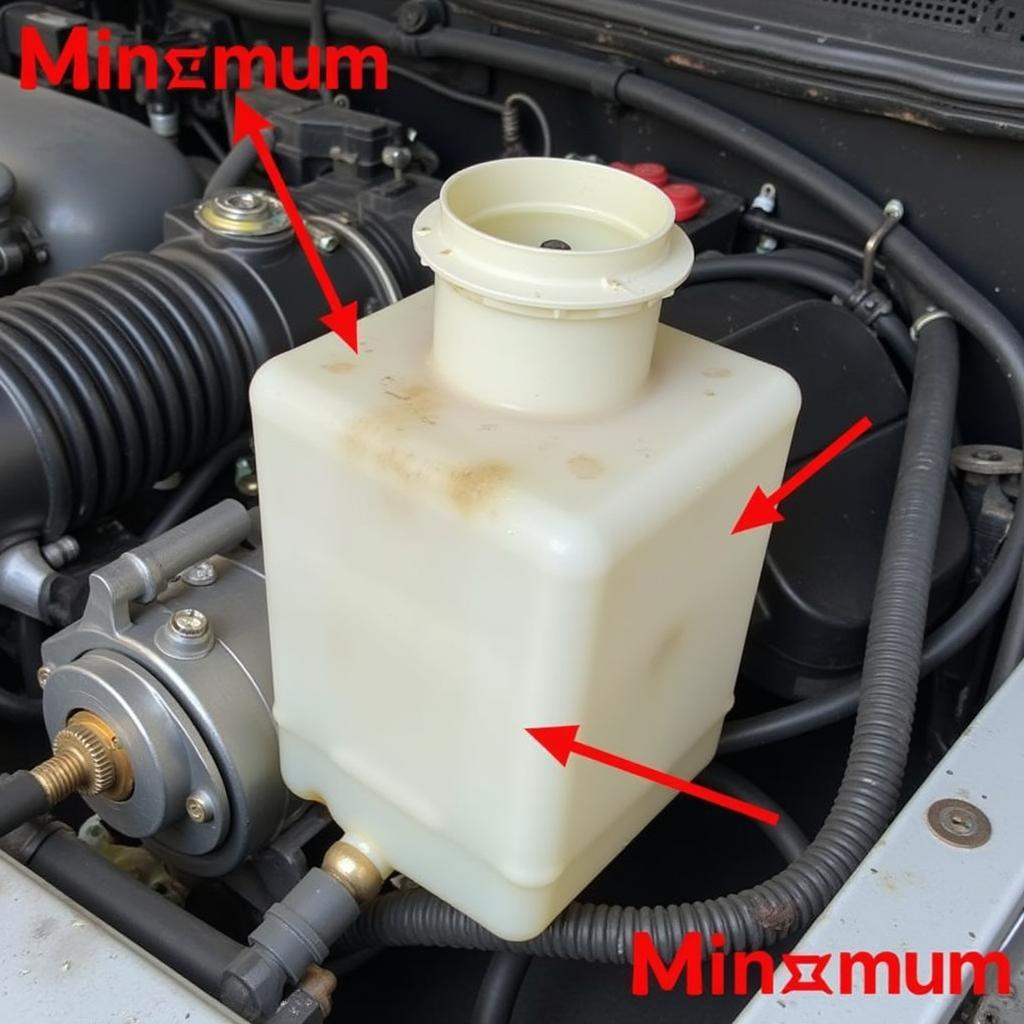

1. Inspect Brake Fluid Level: Begin by checking the brake fluid level in the reservoir. If it’s low, add fluid to the reservoir.

2. Examine Brake Lines and Components: Carefully inspect all brake lines for leaks. Check the brake calipers, wheel cylinders, and master cylinder for signs of leakage.

3. Check for Air in the Brake Lines: If you suspect air in the lines, bleed the brakes to remove it.

4. Inspect Brake Master Cylinder: Inspect the master cylinder for signs of wear, damage, or leakage.

5. Assess Brake Booster Function: Test the brake booster by pressing the brake pedal without the engine running. If the pedal feels hard, the booster may be defective.

6. Consult Diagnostic Tools: If the issue persists, use a diagnostic tool to check the EBS system for error codes. This can provide further insight into the problem.

Solutions for the 05 International 4200 Brake Pressure Warning

Once you’ve identified the cause of the brake pressure warning, you can implement the appropriate solutions:

1. Replenish Brake Fluid: If the issue is low brake fluid, simply replenish the reservoir with the correct type of brake fluid.

2. Repair or Replace Leaky Components: Repair or replace any leaking brake lines, calipers, wheel cylinders, or master cylinder.

3. Bleed the Brakes: If air is present in the brake lines, bleed them to remove it.

4. Replace the Brake Master Cylinder: If the master cylinder is faulty, replace it with a new one.

5. Repair or Replace the Brake Booster: If the brake booster is defective, repair or replace it.

6. Address Electrical Problems: If the issue is electrical, check wiring, sensors, and the EBS control unit for problems.

Expert Insight:

“Always prioritize safety when dealing with brake issues. If you’re unsure about the cause or solution, seek assistance from a qualified mechanic with expertise in commercial truck braking systems.”

– John Smith, Automotive Technician, ABC Truck Repair

FAQ:

Q: What happens if I ignore the 05 International 4200 brake pressure warning?

A: Ignoring this warning can lead to severe consequences, including brake failure, accidents, and potential injuries.

Q: Can I drive my truck with the brake pressure warning light on?

A: No, it’s unsafe to drive with this warning light illuminated. It indicates a potential brake system malfunction, and you should pull over immediately.

Q: How often should I check my brake fluid level?

A: You should check your brake fluid level regularly, especially before long trips. A visual inspection should suffice, and you can top off the fluid if necessary.

Q: What are the signs of a bad brake master cylinder?

A: Signs of a bad brake master cylinder include a soft brake pedal, a spongy feeling when applying brakes, a slow return to the brake pedal, and a low brake fluid level.

Q: Can I use any type of brake fluid in my truck?

A: No, use only the type of brake fluid specified in your truck’s owner’s manual. Using the wrong type of fluid can damage the braking system.

By understanding the causes, troubleshooting steps, and solutions for the 05 International 4200 brake pressure warning, you can ensure the safety of your truck and yourself on the road. Remember, early detection and prompt action are key to avoiding costly repairs and potential hazards.