If you own a classic 1984 Mercedes 500, you understand the satisfaction of keeping this automotive legend running smoothly. However, like any machine with age, you’re bound to encounter some hiccups along the way, especially with the distributor system. This guide dives deep into 1984 Mercedes 500 distributor diagnostics, offering insights and practical advice to help you tackle those issues head-on.

Understanding Your 1984 Mercedes 500 Distributor

Before we jump into diagnostics, let’s recap why the distributor is so crucial. This electromechanical marvel is responsible for:

- Distributing High Voltage: The distributor takes the high voltage from the ignition coil and delivers it to each spark plug at precisely the right time.

- Timing is Everything: Accurate ignition timing is essential for optimal engine performance, fuel efficiency, and minimal emissions. The distributor ensures this timing is spot-on.

Common 1984 Mercedes 500 Distributor Problems

Several components within the distributor system can wear out or fail, leading to performance issues. Here are some common culprits:

- Worn Distributor Cap and Rotor: Cracks, carbon tracking, or excessive wear on these components can disrupt the flow of high voltage, leading to misfires and poor engine performance.

- Faulty Ignition Points (if equipped): These contact points, responsible for triggering the spark, can wear down or become misaligned, causing inconsistent sparking.

- Vacuum Advance Issues: The vacuum advance mechanism alters ignition timing based on engine load. A malfunction here can lead to poor fuel economy, sluggish acceleration, and detonation (knocking).

- Mechanical Wear: Over time, the distributor shaft bearings can wear out, causing excessive play and timing fluctuations.

Diagnosing Distributor Problems

A well-running distributor is vital for your Mercedes 500. Here’s what to look out for if you suspect distributor trouble:

- Engine Performance Issues: Rough idling, misfires, backfiring, poor acceleration, and difficulty starting are common signs of distributor problems.

- Check Engine Light: While not as sophisticated as modern onboard diagnostics, the check engine light can illuminate if the engine control unit (ECU) detects an issue related to ignition timing.

- Visible Damage: Inspect the distributor cap and rotor for visible cracks, carbon tracking, or corrosion.

- Unusual Sounds: Listen for any unusual noises coming from the distributor area, such as clicking, grinding, or whining, which can indicate mechanical wear.

DIY Diagnostics and Troubleshooting

If you’re mechanically inclined, you can perform some basic distributor diagnostics yourself:

- Visual Inspection: Start by visually inspecting the distributor cap, rotor, and wiring for any signs of damage or wear.

- Check Spark Plug Wires: Ensure the spark plug wires are properly connected and in good condition.

- Inspect Ignition Points (if equipped): If your model still uses ignition points, check their condition and gap using a feeler gauge. Refer to your owner’s manual for the correct specifications.

- Test Vacuum Advance: With the engine off, disconnect the vacuum line to the advance unit and suck on it. You should feel a vacuum and see the timing plate move. If not, the advance unit may be faulty.

When to Call in the Pros

While DIY diagnostics can be helpful, certain tasks are best left to experienced mechanics:

- Distributor Timing Adjustment: Accurate timing is essential for optimal performance. This requires specialized tools and knowledge.

- Complex Electrical Diagnostics: If basic troubleshooting doesn’t pinpoint the issue, a mechanic with advanced diagnostic equipment can help.

- Component Replacement: While replacing a distributor cap or rotor can be a DIY job, more complex repairs, like replacing the entire distributor, are best handled by a professional.

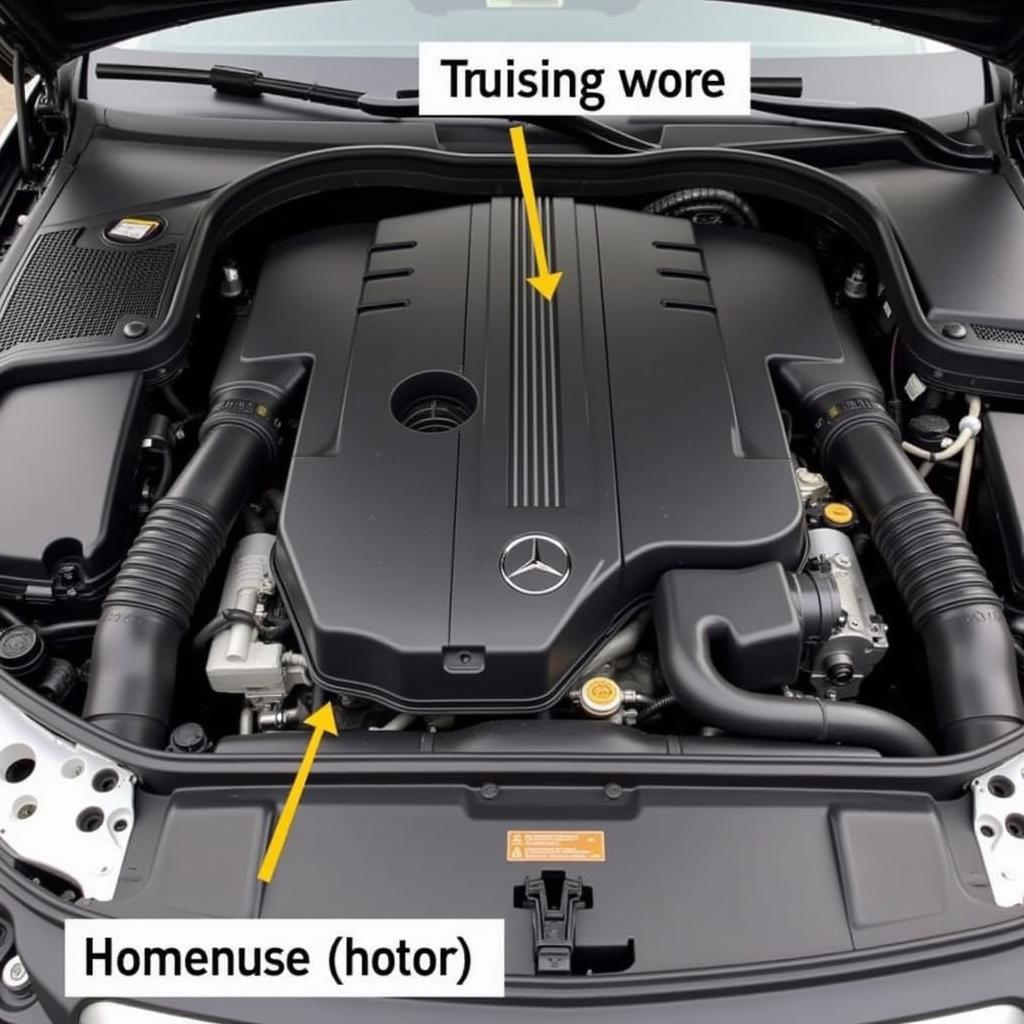

Distributor Cap and Rotor

Distributor Cap and Rotor

Frequently Asked Questions

Q: How often should I replace my Mercedes 500’s distributor cap and rotor?

A: While it varies depending on usage and conditions, it’s generally a good idea to replace them every 30,000-60,000 miles as part of preventative maintenance.

Q: Can I use aftermarket distributor parts on my 1984 Mercedes 500?

A: While aftermarket options are available, using high-quality, OEM (Original Equipment Manufacturer) or equivalent parts is recommended for optimal performance and longevity.

Q: My engine is backfiring. Could this be a distributor problem?

A: Yes, a backfiring engine can be a symptom of incorrect ignition timing, potentially caused by a faulty distributor.

Professional Automotive Insights

“Maintaining your classic Mercedes 500’s distributor is crucial for its performance and longevity,” says master mechanic Johnathan Bentley, author of Classic German Auto Electrical Systems. “Regular inspection and timely replacement of wear items can prevent more serious issues down the road.”

Timing Light in Use

Timing Light in Use

Keep Your Classic Running Smoothly

The distributor plays a vital role in keeping your 1984 Mercedes 500 running at its best. By understanding how it works, recognizing the signs of potential problems, and knowing when to seek professional help, you can ensure that this automotive icon continues to provide you with miles of driving enjoyment.

For more in-depth diagnostic tools and resources, consider exploring Cardiagtech’s range of automotive diagnostic products.

Need further assistance with your Mercedes 500? Connect with the experts at CARDIAGTECH for personalized support.