The dreaded parking brake warning light on your 2006 Freightliner M2 can be a real headache. Whether it’s stubbornly staying on, flickering intermittently, or accompanied by a frustrating beep, this issue demands attention. This comprehensive guide will walk you through the common causes, diagnostic steps, and solutions for a 2006 Freightliner M2 parking brake warning light, helping you get back on the road safely and efficiently.

Understanding the Parking Brake System

Before diving into troubleshooting, it’s helpful to understand how the parking brake system works in your 2006 Freightliner M2. The system typically involves a combination of mechanical and electrical components, including the parking brake lever/pedal, cables, brake shoes/drums, and a series of sensors and switches. These components work together to engage and disengage the parking brake, ensuring your truck remains securely parked. A malfunction in any of these parts can trigger the warning light.

Common Causes of a 2006 Freightliner M2 Parking Brake Warning Light

Several factors can contribute to the parking brake warning light illuminating on your dashboard. These range from simple issues like a low brake fluid level to more complex problems involving faulty sensors or wiring.

-

Low Brake Fluid: One of the most common culprits is a low brake fluid level. This can indicate a leak in the braking system, worn brake pads, or other issues requiring immediate attention.

-

Faulty Parking Brake Switch: The parking brake switch, located near the lever or pedal, can malfunction, sending a false signal to the warning light even when the parking brake is fully disengaged.

-

Worn Brake Shoes/Drums: Over time, the brake shoes and drums can wear down, affecting the parking brake’s effectiveness and potentially triggering the warning light.

-

Wiring Issues: Damaged or corroded wiring within the parking brake system can disrupt the signal flow and cause the warning light to illuminate.

-

ABS Issues: While less common, problems with the Anti-lock Braking System (ABS) can sometimes also trigger the parking brake warning light.

Diagnosing the Problem

Diagnosing the root cause of the warning light requires a systematic approach.

-

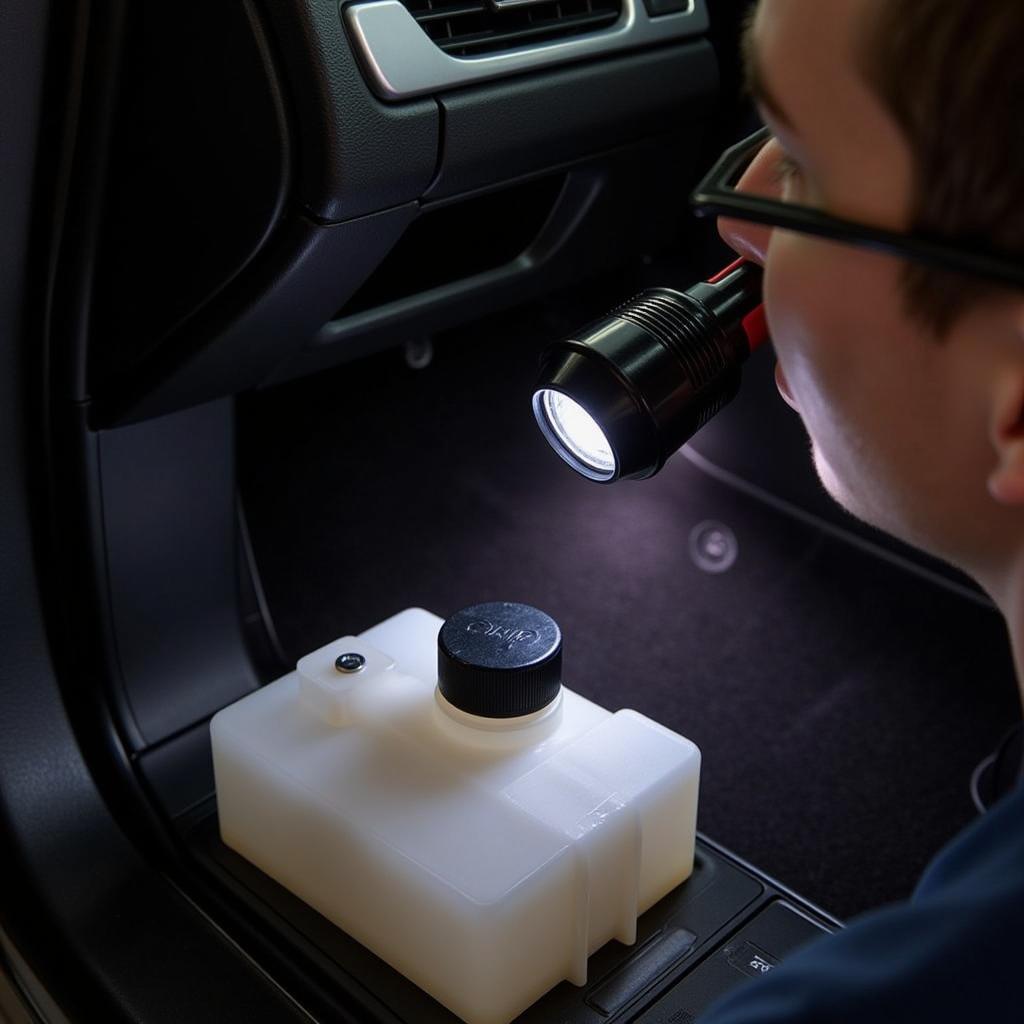

Check the Brake Fluid Level: Start by checking the brake fluid reservoir. If the level is low, top it off and monitor for further leaks.

-

Inspect the Parking Brake Lever/Pedal: Ensure the lever is fully released or the pedal is fully up. Sometimes a slight misalignment can trigger the warning light.

-

Test the Parking Brake Switch: Use a multimeter to test the continuity of the parking brake switch. If the switch is faulty, replace it.

-

Inspect Brake Shoes/Drums: Check the condition of the brake shoes and drums for excessive wear. If necessary, replace them.

-

Check Wiring and Connections: Inspect the wiring harness and connections for any signs of damage or corrosion. Repair or replace any faulty wiring.

Troubleshooting with Remote Diagnostics

As a specialist in remote diagnostics, programming, and software installation for automotive repair, I can often diagnose and resolve these issues remotely. Using specialized software, I can access your vehicle’s electronic control units (ECUs) and identify any fault codes related to the parking brake system. This allows for a quick and efficient diagnosis, saving you valuable time and money. Sometimes, a simple software update or recalibration can resolve the issue without any physical intervention.

“Remote diagnostics offer a powerful tool for troubleshooting modern vehicles like the Freightliner M2. We can often pinpoint the problem quickly and efficiently, minimizing downtime and getting you back on the road faster.” – John Miller, Senior Automotive Diagnostics Technician.

Preventing Future Issues

Regular maintenance is crucial for preventing parking brake problems. This includes regular brake inspections, fluid checks, and timely replacement of worn components.

-

Regular Brake Inspections: Have your brakes inspected by a qualified technician at least once a year or as recommended by Freightliner.

-

Fluid Checks: Regularly check your brake fluid level and top it off as needed.

-

Timely Component Replacement: Replace worn brake shoes, drums, and other components as soon as they show signs of wear.

Conclusion

The 2006 Freightliner M2 parking brake warning light should never be ignored. Addressing the issue promptly can prevent further damage and ensure your safety on the road. By following the diagnostic steps outlined in this guide and considering remote diagnostic options, you can effectively troubleshoot and resolve the problem. Remember, regular maintenance is key to preventing future parking brake issues and keeping your Freightliner M2 running smoothly.

“Don’t underestimate the importance of preventative maintenance. Regularly checking your brakes and other crucial systems can save you a lot of headaches and expense down the road.” – Sarah Johnson, Certified Automotive Mechanic.

FAQ

-

What should I do if the parking brake warning light stays on even after releasing the parking brake? Check the brake fluid level and inspect the parking brake switch. If these seem fine, consider professional diagnostics.

-

Can a low battery cause the parking brake warning light to come on? While unlikely, a severely low battery can sometimes cause unusual warning light behavior. Check your battery voltage.

-

How much does it cost to replace a parking brake switch? The cost varies depending on the specific switch and labor rates. Expect to pay between $50 and $200.

-

Can I drive with the parking brake warning light on? It’s not recommended. The warning light indicates a potential problem with your braking system.

-

How often should I have my brakes inspected? At least once a year or as recommended by Freightliner.

-

What is remote diagnostics? Remote diagnostics involves using specialized software to access your vehicle’s computer systems and diagnose problems remotely.

-

Is it safe to use remote diagnostics? Yes, reputable remote diagnostic services use secure connections and do not interfere with your vehicle’s operation.