Engine turning, also known as damascening or jeweling, is a meticulous process of embellishing metal surfaces with intricate, overlapping patterns. While not unique to Mercedes-Benz, the technique is often associated with the luxurious engine compartments of classic Mercedes models. Achieving this look requires a specialized tool – the Mercedes engine turning tool.

This comprehensive guide delves into the intricacies of the Mercedes engine turning tool, exploring its functions, benefits, and addressing common queries from automotive enthusiasts.

Understanding the Mercedes Engine Turning Tool

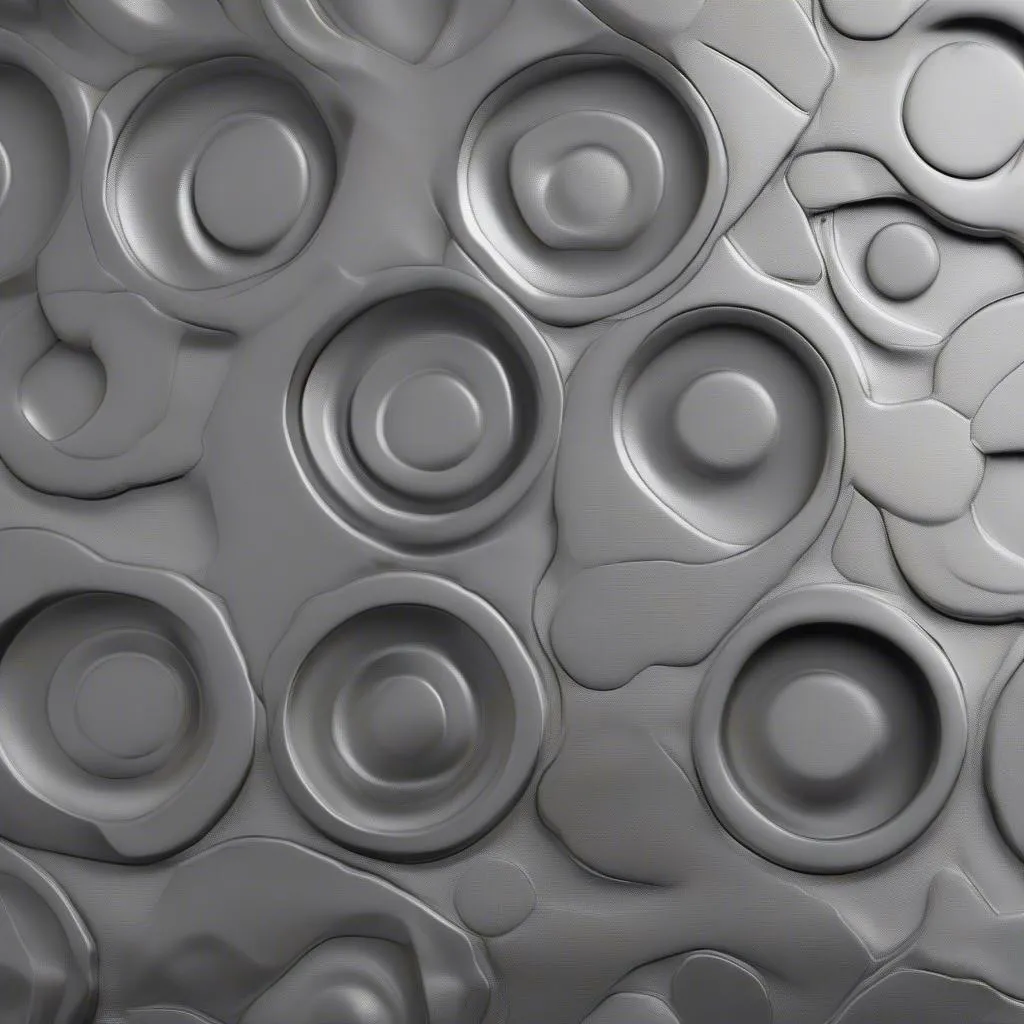

The Mercedes engine turning tool, in essence, is a specialized abrasive tool designed for creating the signature engine turning pattern. While the specific design can vary, it generally comprises a rotating abrasive head, often felt or rubber, mounted on a handheld shaft. This head is charged with a fine abrasive compound.

Mercedes Engine Turning Tool

Mercedes Engine Turning Tool

Applications and Advantages

The primary function of the Mercedes engine turning tool is to produce a consistent, circular pattern on metal surfaces. This is achieved by delicately moving the rotating head across the workpiece in overlapping circles. The resulting finish not only enhances the aesthetic appeal of the engine bay but also serves practical purposes:

- Reduced Glare: The engine turning pattern helps to diffuse light, minimizing glare from the engine components.

- Concealed Imperfections: It effectively masks minor surface imperfections on the metal.

- Enhanced Oil Retention: The textured surface can improve oil retention, aiding lubrication.

Choosing and Using a Mercedes Engine Turning Tool

Selecting the appropriate engine turning tool depends on factors such as the size and shape of the workpiece, the desired finish, and personal preference.

“When working with intricate engine parts, precision is key,” says John Miller, a seasoned automotive engineer and author of “Automotive Engine Aesthetics.” “Opting for a tool with adjustable speed and pressure settings allows for greater control, ensuring a professional-looking finish.”

Engine Turned Metal Finish

Engine Turned Metal Finish

Tips for Optimal Results:

- Surface Preparation: Thoroughly clean and prepare the metal surface before beginning. Any dirt or debris can compromise the final result.

- Consistent Pressure: Apply consistent, gentle pressure throughout the process to ensure a uniform pattern.

- Overlapping Circles: Overlap each circle slightly to create the desired effect.

- Practice Makes Perfect: Like any skilled craft, engine turning demands practice. Start with scrap metal pieces to gain proficiency.

Addressing Common Queries

Q: Is the Mercedes engine turning tool suitable for other car brands?

A: Absolutely! While often associated with Mercedes, this tool is not limited to a specific car brand. It can be employed on any metal surface where an engine-turned finish is desired.

Q: Can I achieve the same finish with a regular rotary tool?

A: While some rotary tools offer polishing attachments, they often lack the precision and control of a dedicated engine turning tool, making it difficult to achieve the same professional outcome.

Q: Where can I purchase a Mercedes engine turning tool?

A: Reputable automotive tool suppliers, both online and offline, typically carry engine turning tools. Cardiagtech, known for its comprehensive range of automotive diagnostic and repair tools, could be a good starting point for your search.

Conclusion

The Mercedes engine turning tool embodies the perfect blend of artistry and functionality. While the process requires patience and a meticulous hand, the stunning results speak for themselves. Transforming a mundane engine bay into a visual masterpiece, this tool enables you to add a touch of vintage elegance and personalized detail to your automotive endeavors.

For further guidance on automotive tools and techniques, connect with CARDIAGTECH – your one-stop resource for all things automotive.