The VCDS injector test, also known as the TDI timing check, is a crucial diagnostic procedure for vehicles equipped with diesel engines, particularly those with direct injection systems. This test, performed using the VCDS (Vag-Com System) diagnostic software, helps determine the health and performance of your car’s fuel injectors.

Why Injector Testing Matters

Fuel injectors play a vital role in your engine’s combustion process. They are responsible for precisely atomizing and delivering fuel into the combustion chamber at the right time and pressure. Faulty or poorly performing injectors can lead to a range of issues, including:

- Reduced engine power and performance

- Poor fuel economy

- Rough idling

- Increased emissions

- Difficulty starting

Regular injector testing using VCDS allows you to identify potential problems early, preventing costly repairs and ensuring optimal engine performance.

fuel-injector|fuel injector|Close-up photo of a car fuel injector

Performing a VCDS Injector Test

Before initiating the test, ensure you have the following:

- A compatible Windows-based laptop

- A genuine VCDS interface cable

- The latest version of the VCDS software installed

connecting-vcds-cable|VCDS cable connection|Photo of a mechanic’s hand connecting a VCDS cable to a car’s OBD-II port

Steps:

- Connect the VCDS interface: Connect the VCDS cable to your laptop’s USB port and the vehicle’s OBD-II port.

- Turn on the ignition: Switch on the ignition but do not start the engine.

- Launch VCDS software: Open the VCDS software on your laptop and establish communication with your vehicle’s ECU.

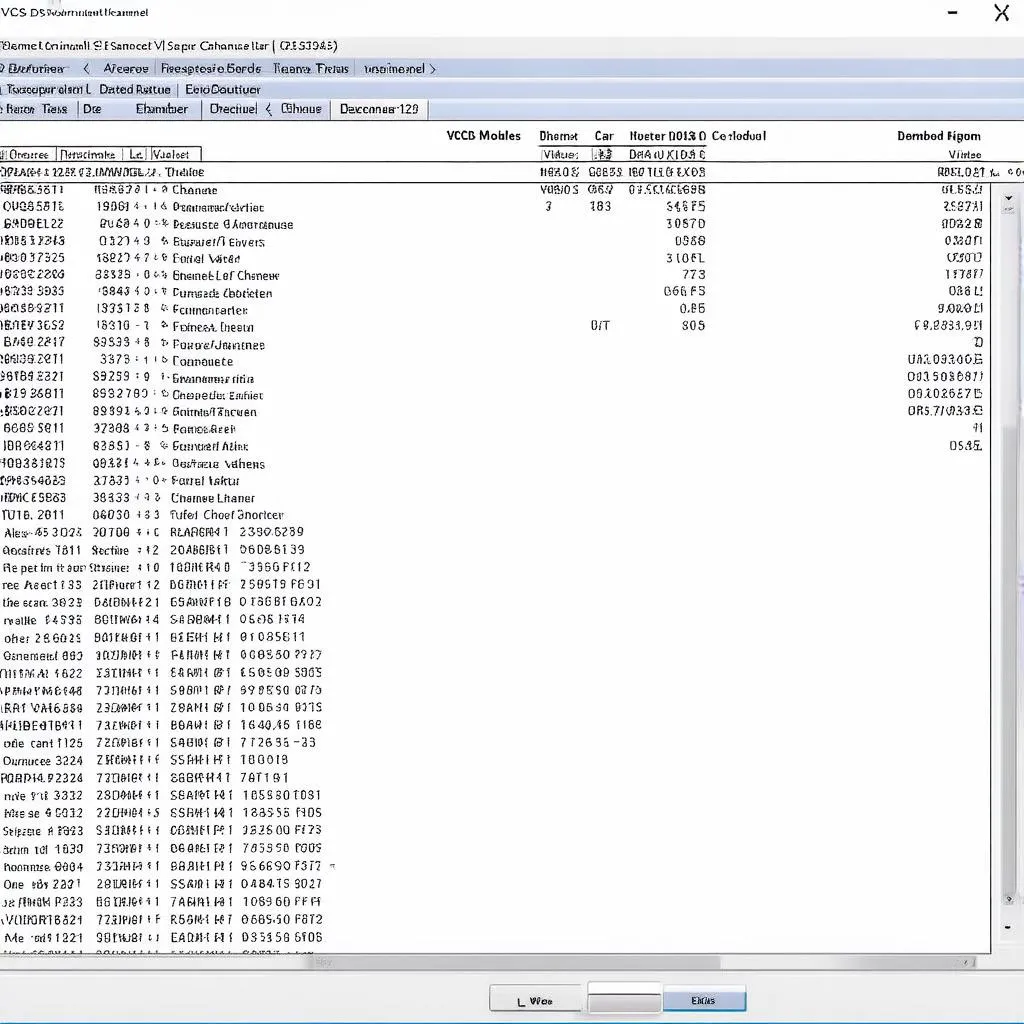

- Select Engine module: Navigate to the “Engine” module within the VCDS software.

- Access Measuring Blocks: Choose “Measuring Blocks” or “Measuring Values” from the options.

- Select Injector Group: Identify and select the measuring block group related to injector quantity or injection deviation.

- Monitor values: Observe the displayed values for each injector. Ideal values will typically hover around zero. Significant deviations may indicate a problem with one or more injectors.

Note: Specific measuring block groups and acceptable value ranges may vary depending on your vehicle’s make, model, and engine type. Refer to your vehicle’s service manual or consult with a qualified technician for precise information.