A Warner brake controller is an essential component for safe towing, allowing you to control the trailer brakes independently from your vehicle’s brakes. However, like any electronic system, it can encounter issues. This comprehensive guide will cover common Warner brake controller problems, troubleshooting tips, and expert advice on remote software diagnostics, programming, and installation for effective solutions.

Types of Warner Brake Controllers

Types of Warner Brake Controllers

Understanding Your Warner Brake Controller

Before delving into troubleshooting, it’s crucial to understand the type of Warner brake controller you have:

- Time-Based Controllers: These controllers apply brakes based on a pre-set time delay, gradually increasing braking power.

- Inertia-Based Controllers: These controllers use an internal sensor to detect the vehicle’s deceleration and apply proportional trailer braking force.

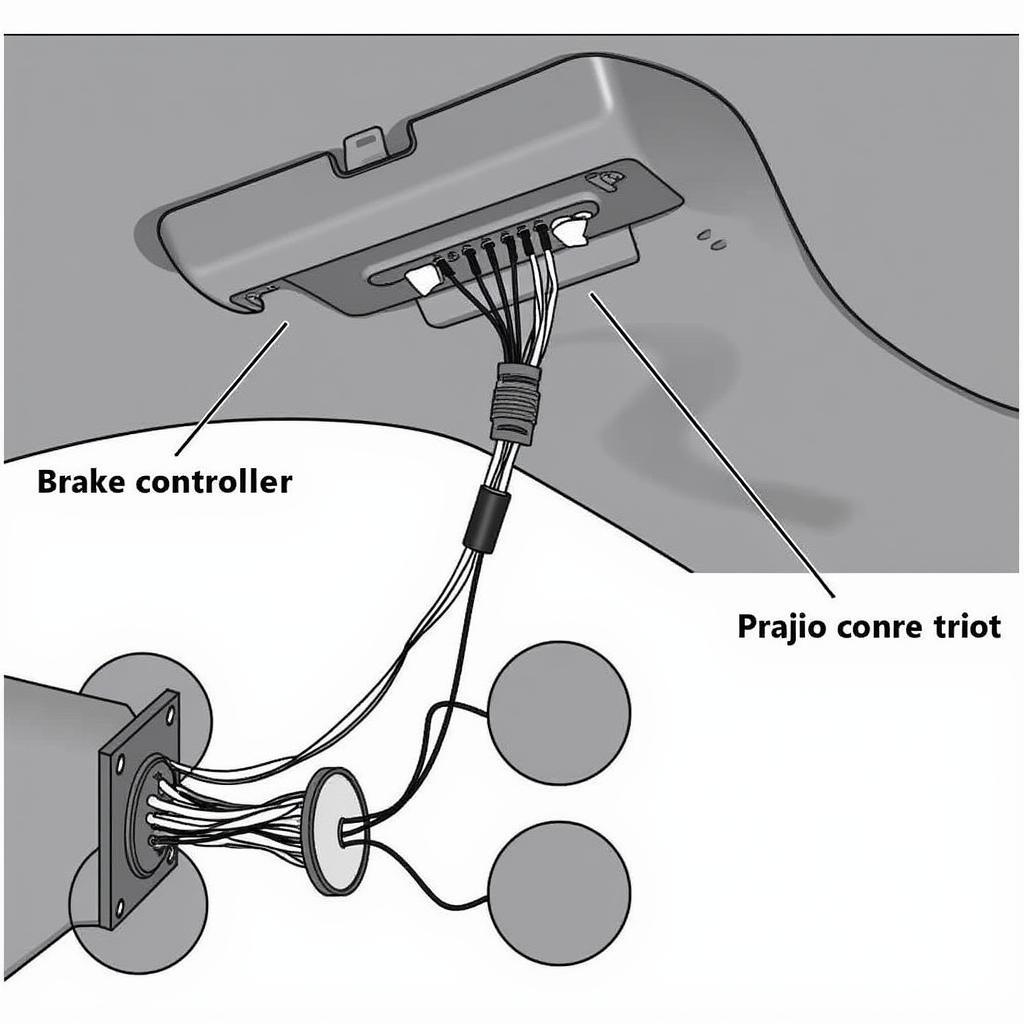

Warner Brake Controller Installation in a Vehicle

Warner Brake Controller Installation in a Vehicle

Common Warner Brake Controller Problems and Solutions

Here’s a breakdown of frequently encountered issues and how to address them:

1. No Trailer Brakes:

- Possible Causes: Blown fuse, loose wiring, faulty brake controller, malfunctioning trailer brake magnets.

- Troubleshooting:

- Check the fuse related to the brake controller circuit.

- Inspect all wiring connections between the controller and the trailer.

- Use a multimeter to test the voltage output from the controller when the manual override is activated.

- Test the trailer brake magnets for proper resistance.

2. Trailer Brakes Lock Up:

- Possible Causes: Short circuit in the wiring, faulty brake controller, incorrect gain setting.

- Troubleshooting:

- Carefully inspect the wiring harness for any signs of damage or exposed wires.

- Gradually decrease the gain setting on the brake controller until the wheels stop locking.

- If the problem persists, consider having the brake controller tested.

3. Intermittent Trailer Braking:

- Possible Causes: Loose connections, corroded wiring, faulty brake controller.

- Troubleshooting:

- Ensure all wiring connections are clean, tight, and secure.

- Check the trailer plug and the vehicle’s 7-pin connector for corrosion or damage.

- Wiggle the wiring harness while activating the manual override to identify any intermittent connections.

4. Brake Controller Display Errors:

- Possible Causes: Internal controller error, communication issue with the vehicle.

- Troubleshooting:

- Consult the user manual for specific error code definitions and troubleshooting steps.

- Disconnect the brake controller from the power source for a few minutes and then reconnect.

- If the error persists, remote software diagnostics can pinpoint the issue.

Technician Performing Remote Diagnostics on a Warner Brake Controller

Technician Performing Remote Diagnostics on a Warner Brake Controller

The Advantages of Remote Software Diagnostics

As a specialist in automotive electrical engineering, I often utilize remote software diagnostics for accurate and efficient Warner brake controller repair. Here’s why:

- Pinpoint Accuracy: Specialized software can interface with the brake controller, reading error codes and analyzing system data to identify the root cause of the problem.

- Time-Saving: Remote diagnostics eliminate the need to physically visit a repair shop for initial assessment, saving valuable time.

- Cost-Effective: Identifying the problem remotely can often prevent unnecessary repairs or part replacements.

Remote Programming and Software Updates

Beyond diagnostics, remote programming allows for:

- Customized Braking Performance: Fine-tune brake controller settings to match your specific trailer and driving preferences.

- Software Updates: Installing the latest software ensures optimal performance, compatibility with newer vehicles, and access to advanced features.

Expert Installation for Optimal Performance

While some DIY enthusiasts may choose to install their own brake controllers, seeking professional installation offers several advantages:

- Correct Wiring: Proper wiring ensures the brake controller functions safely and effectively.

- Vehicle Compatibility: Professionals can determine the correct wiring harness and mounting location for your specific vehicle model.

- Peace of Mind: Knowing the installation meets safety standards provides added confidence when towing.

Conclusion

A properly functioning Warner brake controller is essential for safe and controlled towing. By understanding common problems and utilizing remote diagnostics, programming, and professional installation, you can ensure a smooth and secure towing experience. Remember to consult your user manual or contact a qualified automotive electrician for assistance with any complex issues.

supply warner electric brake clutch

Frequently Asked Questions

1. How often should I have my Warner brake controller serviced?

It’s recommended to have your brake controller inspected annually or every 12,000 miles, along with your regular vehicle maintenance.

2. Can I use my Warner brake controller with any trailer?

Warner brake controllers are compatible with a wide range of trailers. However, ensure the controller’s electrical capacity meets or exceeds the trailer’s requirements.

3. What does the “gain” setting on my brake controller do?

The gain setting controls the sensitivity of the brake controller. A higher gain setting applies more braking power to the trailer.

4. Can I install a Warner brake controller in my car myself?

While DIY installation is possible, it’s recommended to seek professional installation to ensure proper wiring and safety.

5. My brake controller display is blank. What should I do?

Check the fuse associated with the brake controller circuit. If the fuse is blown, replace it. If the issue persists, consult a qualified technician.