The Warner clutch brake is a critical component in many modern vehicles, playing a vital role in smooth gear changes and efficient power transmission. When issues arise with this system, it can lead to frustrating driving experiences and even safety concerns. This comprehensive guide delves into the intricacies of Warner clutch brakes, empowering you with the knowledge to diagnose, troubleshoot, and potentially resolve problems.

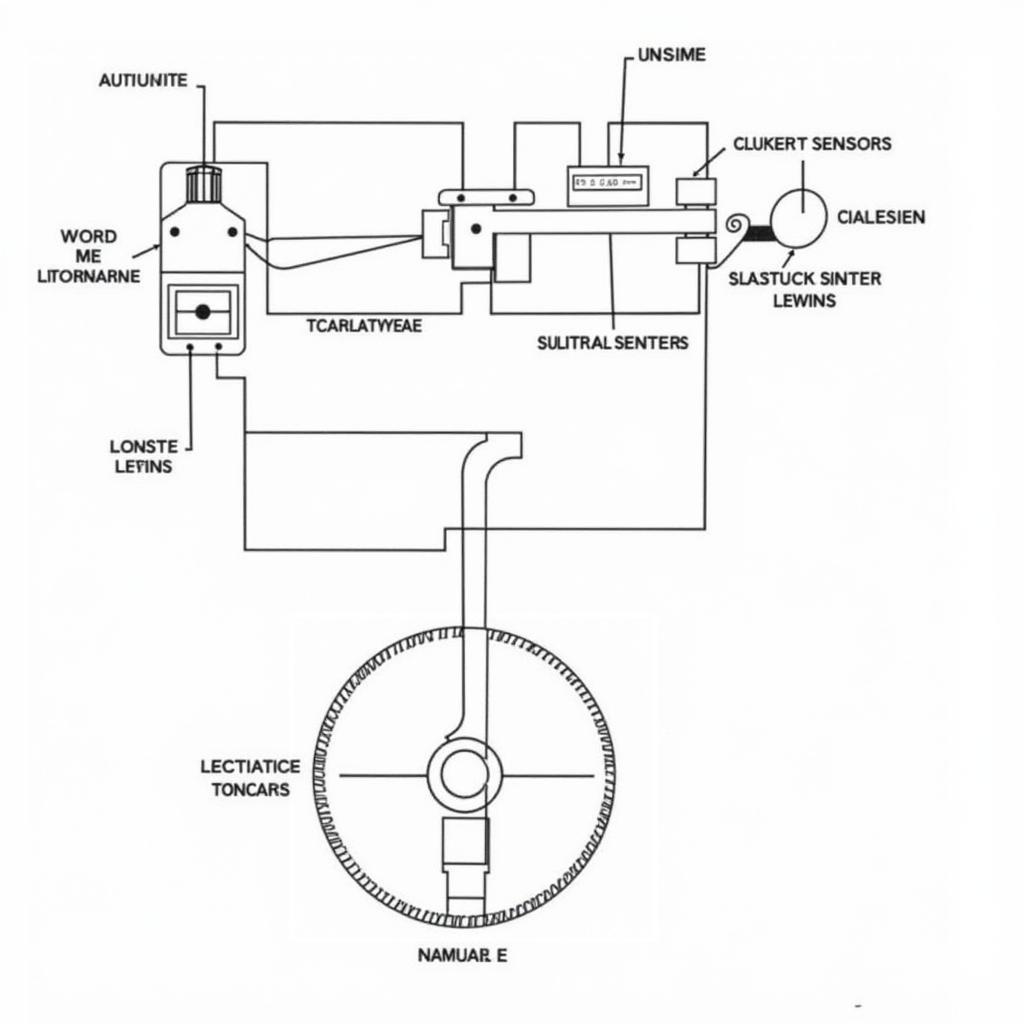

Warner Clutch Brake System Components

Warner Clutch Brake System Components

Understanding the Warner Clutch Brake System

Before diving into troubleshooting, it’s crucial to grasp the fundamentals of how a Warner clutch brake operates. This system, often found in automatic transmissions and some manual transmissions with automated features, utilizes electronic controls to engage and disengage the clutch during gear shifts.

At its core, the system consists of an electronic control unit (ECU), a hydraulic actuator, and various sensors. The ECU acts as the brain, receiving input from sensors monitoring vehicle speed, engine RPM, throttle position, and other parameters. Based on this data, the ECU calculates the optimal timing and force required for clutch engagement and disengagement.

The hydraulic actuator receives commands from the ECU and uses hydraulic pressure to control the clutch brake. This precise control ensures smooth gear changes without driver intervention, enhancing both driving comfort and fuel efficiency.

Common Warner Clutch Brake Problems and Symptoms

While Warner clutch brake systems are designed for reliability, problems can still arise over time due to wear and tear, electrical issues, or hydraulic malfunctions. Recognizing the symptoms of a failing clutch brake is the first step towards a solution.

-

Slipping Clutch: One of the most noticeable symptoms is clutch slippage. This occurs when the clutch fails to fully engage, resulting in a loss of power transmission from the engine to the wheels. You might experience the engine revving up without a corresponding increase in vehicle speed, especially during acceleration.

-

Rough Shifting: A malfunctioning Warner clutch brake can disrupt the smooth engagement and disengagement of the clutch, leading to harsh or jerky gear changes. This can manifest as a noticeable jolt or clunking sound during shifts.

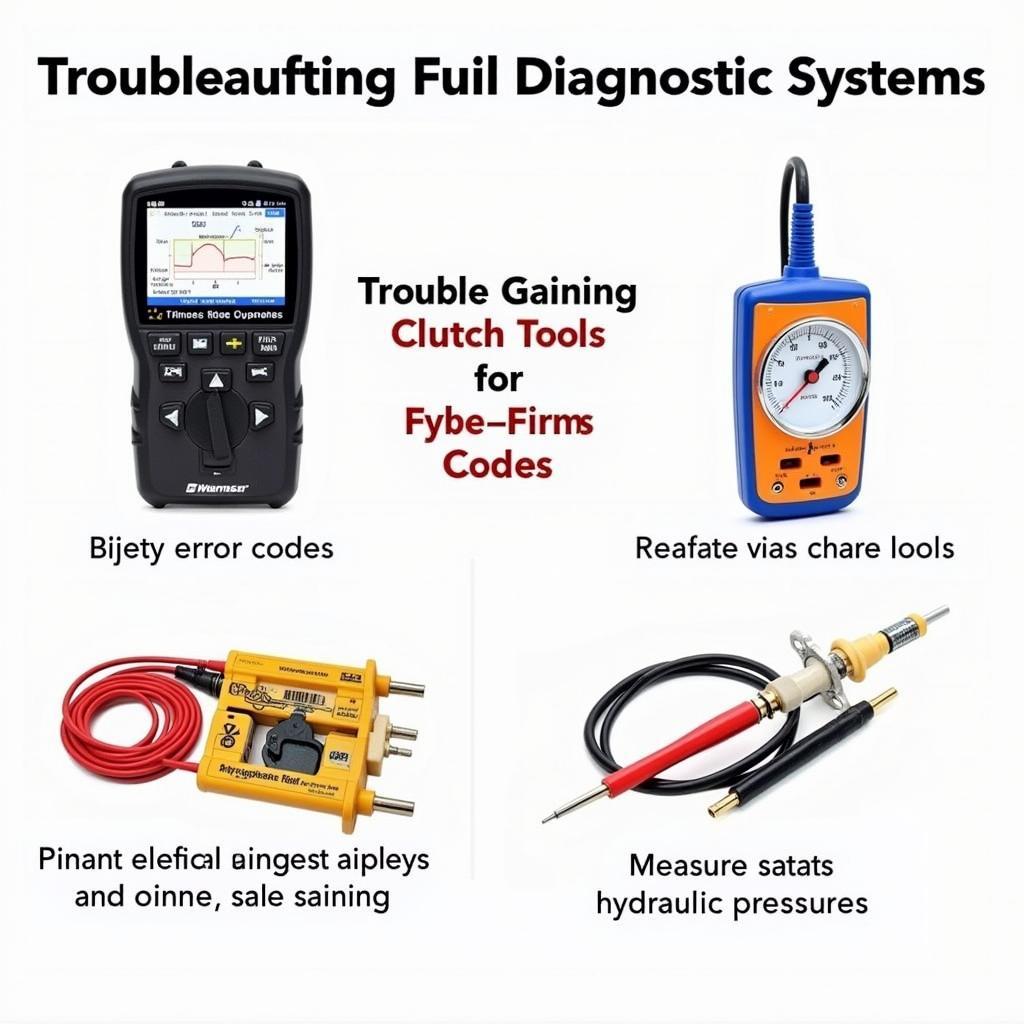

Essential Diagnostic Tools for Warner Clutch Brake Systems

Essential Diagnostic Tools for Warner Clutch Brake Systems

-

Illuminated Warning Lights: Modern vehicles are equipped with sophisticated onboard diagnostic systems. If the ECU detects an issue with the Warner clutch brake, it will trigger a warning light on the dashboard, such as the “Check Engine” light or a transmission-related warning.

-

Inability to Engage Gears: In more severe cases, a complete failure of the Warner clutch brake can render the vehicle unable to engage any gears. This situation often requires immediate attention and professional repair.

Diagnosing Warner Clutch Brake Problems

Accurately diagnosing the root cause of a Warner clutch brake issue is essential for effective repair. While some problems might seem straightforward, others can be quite complex, requiring specialized knowledge and diagnostic equipment.

-

Retrieve Diagnostic Trouble Codes (DTCs): Begin by connecting a professional-grade scan tool to the vehicle’s OBD-II port. This tool allows you to retrieve any stored DTCs related to the Warner clutch brake system. These codes provide valuable clues about the specific area of the system experiencing problems.

-

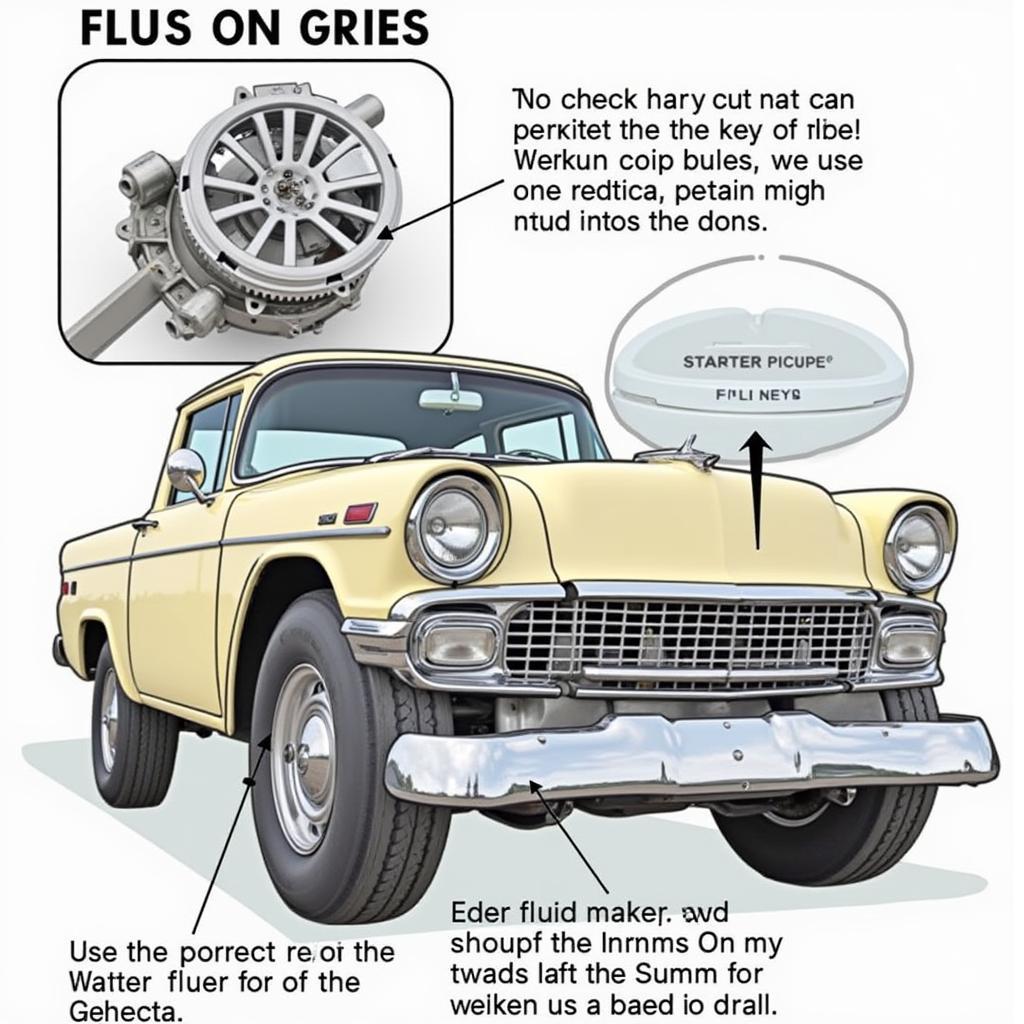

Inspect Hydraulic Fluid: Check the level and condition of the hydraulic fluid used by the clutch actuator. Low fluid levels or contaminated fluid can significantly impact the system’s performance.

Inspecting Warner Clutch Brake Fluid

Inspecting Warner Clutch Brake Fluid

-

Analyze Sensor Data: Using the scan tool, monitor live data from the various sensors that provide input to the ECU, such as the vehicle speed sensor, throttle position sensor, and clutch position sensor. Deviations from expected values can indicate sensor malfunctions or wiring issues.

-

Test Actuator Operation: Inspect the clutch actuator for leaks, damage, or signs of wear. You can also use the scan tool to command the actuator to extend and retract, verifying its proper operation.

Repairing Warner Clutch Brake Problems

Depending on the specific diagnosis, repairing a Warner clutch brake can range from simple component replacements to more involved procedures.

-

Fluid and Filter Change: If the hydraulic fluid is low or contaminated, a simple fluid flush and filter replacement might be sufficient. It’s crucial to use the correct fluid type as specified by the vehicle manufacturer.

-

Sensor Replacement: Faulty sensors, such as the vehicle speed sensor or clutch position sensor, can often be replaced individually. This typically involves disconnecting the old sensor, installing the new one, and clearing any related DTCs.

-

Actuator Repair or Replacement: A leaking or malfunctioning actuator might require repair or replacement. Depending on the design, it might be possible to rebuild the actuator with new seals and components. In other cases, a complete unit replacement might be necessary.

-

ECU Reprogramming or Replacement: In some situations, the ECU itself might be the culprit, requiring reprogramming or replacement. This is a complex procedure best left to experienced technicians with access to specialized software and equipment.

Conclusion

The Warner clutch brake is a sophisticated system that enhances driving comfort and efficiency. By understanding its operation, recognizing common symptoms, and following a systematic diagnostic approach, you can effectively troubleshoot and address issues that may arise. Remember, while some repairs can be handled with basic mechanical skills, more complex problems often necessitate the expertise of qualified automotive technicians. Regular maintenance, including fluid changes and inspections, can help prevent premature wear and extend the lifespan of your Warner clutch brake system.

FAQs

Q: How often should I change the fluid in my Warner clutch brake system?

A: Consult your vehicle’s owner’s manual for specific recommendations. Generally, it’s advisable to have the fluid flushed and replaced every 30,000 to 60,000 miles.

Q: Can I drive my car with a faulty Warner clutch brake?

A: It’s not recommended. Driving with a malfunctioning clutch brake can worsen the problem, potentially leading to more extensive damage and safety hazards.

Q: Where can I find reliable Warner clutch brake parts?

A: It’s essential to use high-quality parts from reputable manufacturers. You can purchase genuine Warner components from authorized dealers, reputable auto parts stores, or explore options for Warner electric brake clutch wholesale.

Q: Is it challenging to replace a Warner clutch brake sensor myself?

A: Replacing a sensor can be a relatively straightforward DIY task for those with basic mechanical skills. However, it’s crucial to consult your vehicle’s repair manual for specific instructions and precautions.

Q: What is the function of the Warner clutch brake control?

A: The Warner clutch brake control is the electronic brain of the system, responsible for managing clutch engagement and disengagement based on various sensor inputs. It ensures smooth gear changes and optimal power transmission.

Q: Can you provide more information about the Warner electric brake and clutch pb-1225?

A: The PB-1225 is a specific model of Warner electric brake and clutch system. For detailed information on this model, including specifications, troubleshooting guides, and repair manuals, you can refer to resources like Warner clutch brake pdf documents or visit websites specializing in Warner products.

Q: Are there reputable Warner electric brake clutch China suppliers?

A: Yes, several reputable suppliers in China offer Warner electric brake clutch components. When sourcing parts internationally, ensure you choose suppliers with a proven track record of quality and reliability. Carefully research and compare options before making a purchase.