Warner Electric brake parts are crucial components found in various vehicles and machinery, ensuring safe and efficient braking operations. As a leading expert in automotive electrical engineering, I specialize in remote diagnostics, programming, and software installation to rectify automotive issues. This comprehensive guide delves into the world of Warner Electric brake parts, equipping you with the knowledge to understand, maintain, and troubleshoot these essential components.

Types of Warner Electric Brakes

Types of Warner Electric Brakes

Understanding Warner Electric Brake Systems

Unlike traditional hydraulic brake systems that rely on fluid pressure, Warner Electric brakes employ electromagnetic force to engage and disengage braking mechanisms. This technology offers numerous advantages, including faster response times, enhanced control, and reduced maintenance requirements.

Types of Warner Electric Brakes

Warner Electric offers a diverse range of brake parts designed for specific applications. Understanding the different types is crucial for proper selection and maintenance:

- Electrically Released Brakes: These brakes remain engaged by default and require electrical power to release. They are commonly found in applications demanding fail-safe operation, such as holding brakes in industrial machinery.

- Electrically Actuated Brakes: In contrast to electrically released brakes, these brakes require electrical power to engage and are typically used in dynamic braking scenarios, providing controlled stopping power.

- Dynamic Brakes: Designed for heavy-duty applications, dynamic brakes utilize the vehicle’s motor as a generator during braking, converting kinetic energy into electrical energy, which is then dissipated as heat.

Common Problems with Warner Electric Brakes

Common Problems with Warner Electric Brakes

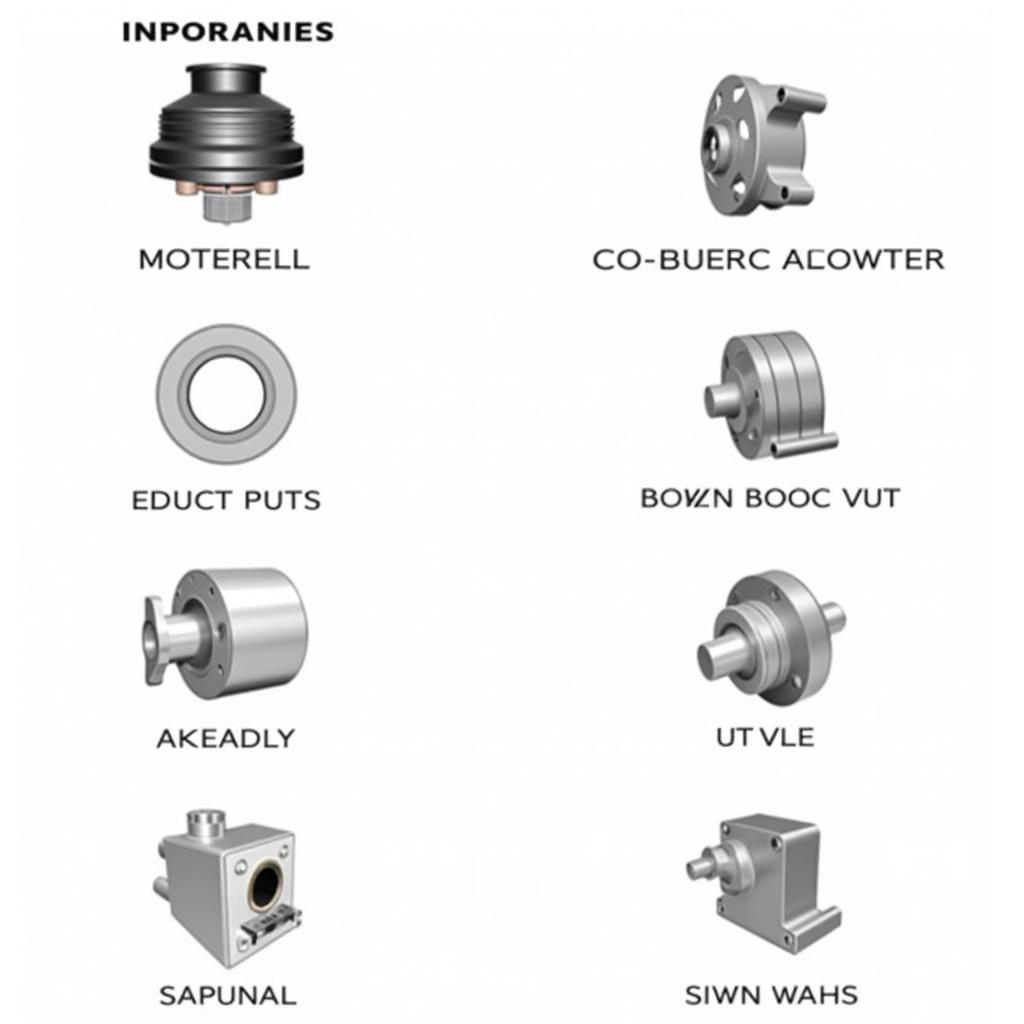

Common Warner Electric Brake Parts and Their Functions

Warner Electric brake systems comprise various components working harmoniously to ensure optimal performance. Let’s explore some of the essential parts:

- Brake Assembly: The heart of the system, housing the electromagnet, armature, and friction material responsible for generating braking force.

- Actuator: This electromechanical device converts electrical signals into mechanical motion, controlling the engagement and disengagement of the brake.

- Friction Disc or Drum: The component that comes into contact with the brake lining to generate friction and slow down or hold the load.

- Brake Controller: An electronic device that regulates the amount of current supplied to the brake, determining the braking force applied.

- Sensors: Components like speed sensors and position sensors provide crucial data to the brake controller, enabling precise control and monitoring of the braking process.

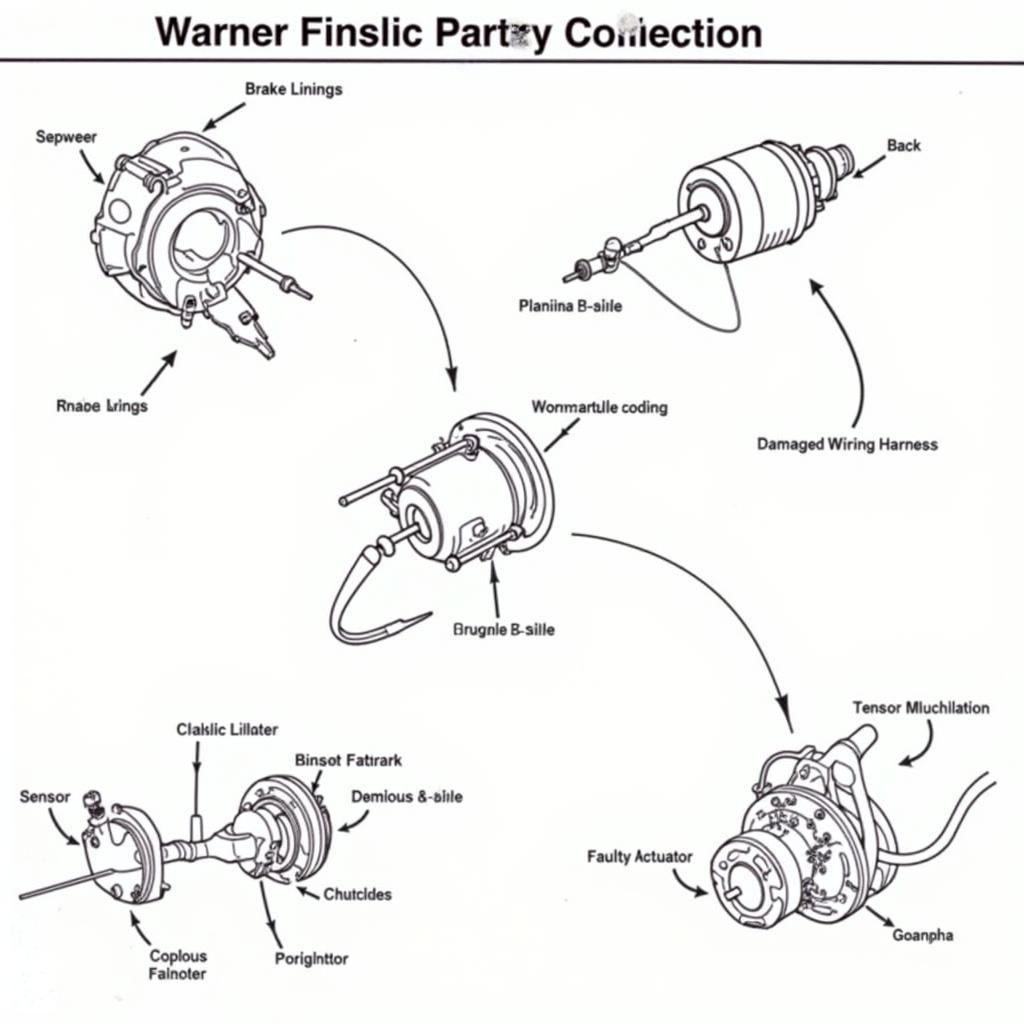

Troubleshooting Warner Electric Brake Problems

Identifying and addressing issues with Warner Electric brake parts is essential for maintaining safety and operational efficiency. Here’s a step-by-step guide to help you troubleshoot common problems:

- Check the Power Supply: Ensure the brake system is receiving the correct voltage and current. Inspect wiring harnesses, fuses, and connections for any damage or loose connections.

- Inspect the Actuator: Verify that the actuator is functioning correctly. Listen for unusual noises, check for physical damage, and test its operation.

- Examine the Friction Material: Worn brake linings or drums can significantly reduce braking performance. Inspect these components for wear and tear and replace them if necessary.

- Diagnose Sensor Issues: Faulty sensors can disrupt the brake controller’s operation. Use diagnostic tools to check for error codes and verify sensor functionality.

Maintenance Tips for Warner Electric Brakes

Maintenance Tips for Warner Electric Brakes

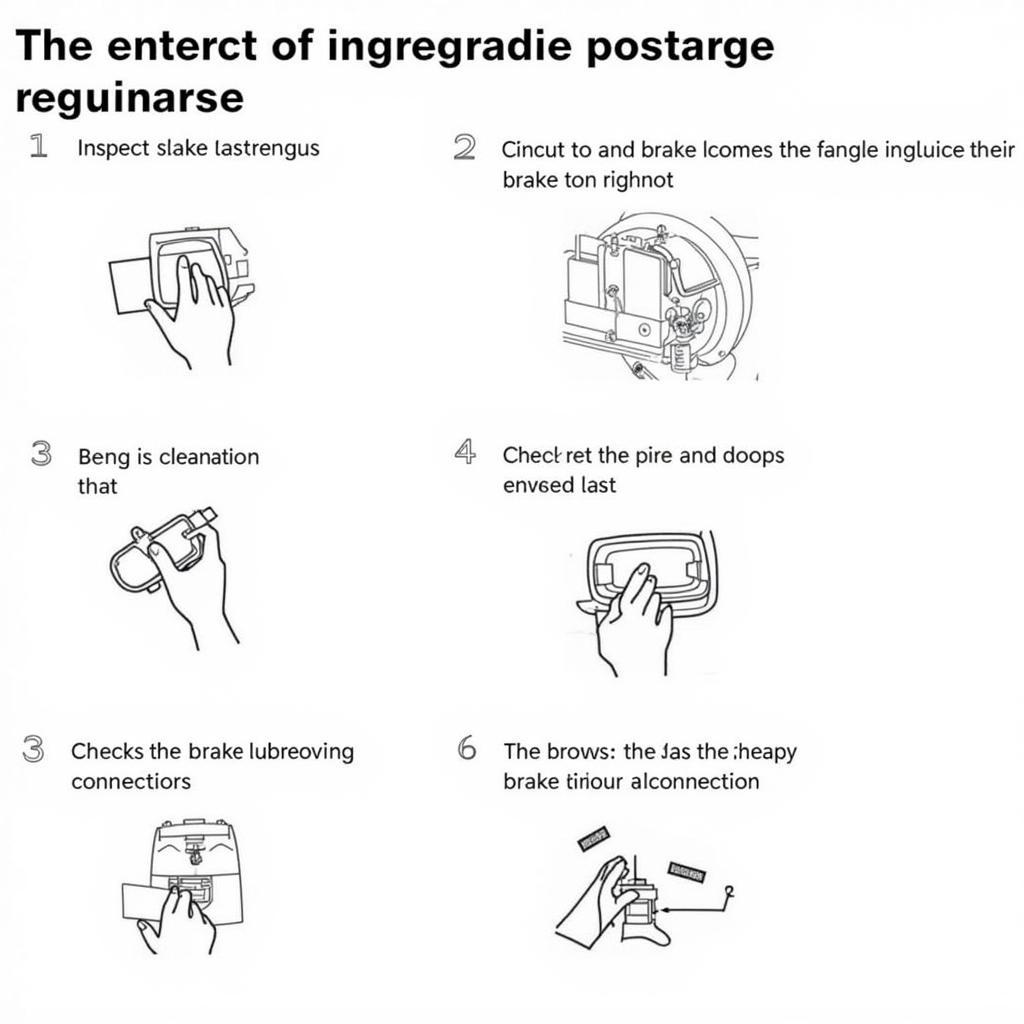

Importance of Regular Maintenance

Regular maintenance is crucial to prevent premature wear and ensure the longevity of your Warner Electric brake parts. Follow these essential maintenance practices:

- Regular Inspections: Conduct visual inspections of brake components for signs of wear, damage, or loose connections.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear.

- Adjustment: Ensure proper brake adjustments to maintain optimal performance and prevent uneven wear.

- Professional Servicing: Consult a qualified technician for comprehensive inspections, adjustments, and replacements when needed.

Conclusion

Warner Electric brake parts play a vital role in ensuring the safety and efficiency of various applications, from automotive to industrial. By understanding the different types, common problems, and maintenance practices, you can contribute to the optimal performance and longevity of these critical components. If you encounter complex issues or require expert assistance, don’t hesitate to seek help from a qualified automotive electrician specializing in Warner Electric brake systems. Remember, prioritizing brake maintenance translates to safer and more reliable operation for your vehicles and equipment.

FAQs

1. What are the advantages of using Warner Electric brakes over hydraulic brakes?

Warner Electric brakes offer faster response times, enhanced control, reduced maintenance, and improved energy efficiency compared to hydraulic counterparts.

2. How often should I replace my Warner Electric brake linings?

The lifespan of brake linings varies depending on usage and operating conditions. However, it’s generally recommended to inspect them at least every 12,000 miles or annually and replace them if they show signs of significant wear.

3. Can I install Warner Electric brake parts myself?

While some maintenance tasks can be performed by individuals with mechanical skills, it’s highly recommended to consult a qualified technician for installations and complex repairs to ensure proper functionality and safety.

4. Where can I find genuine Warner Electric brake parts?

Genuine Warner Electric brake parts are available through authorized dealers and distributors. You can find a list of authorized retailers on the Warner Electric website or contact their customer support for assistance.

5. What should I do if my Warner Electric brakes fail?

If you experience brake failure, safely bring your vehicle or equipment to a stop, engage the parking brake, and seek immediate assistance from a qualified technician.