Warner clutches and brakes are essential components found in various industrial and automotive applications, known for their durability and high-performance capabilities. This article delves into the intricacies of Warner clutches and brakes, exploring their functionality, applications, and the advantages of utilizing remote diagnostics and software solutions for troubleshooting.

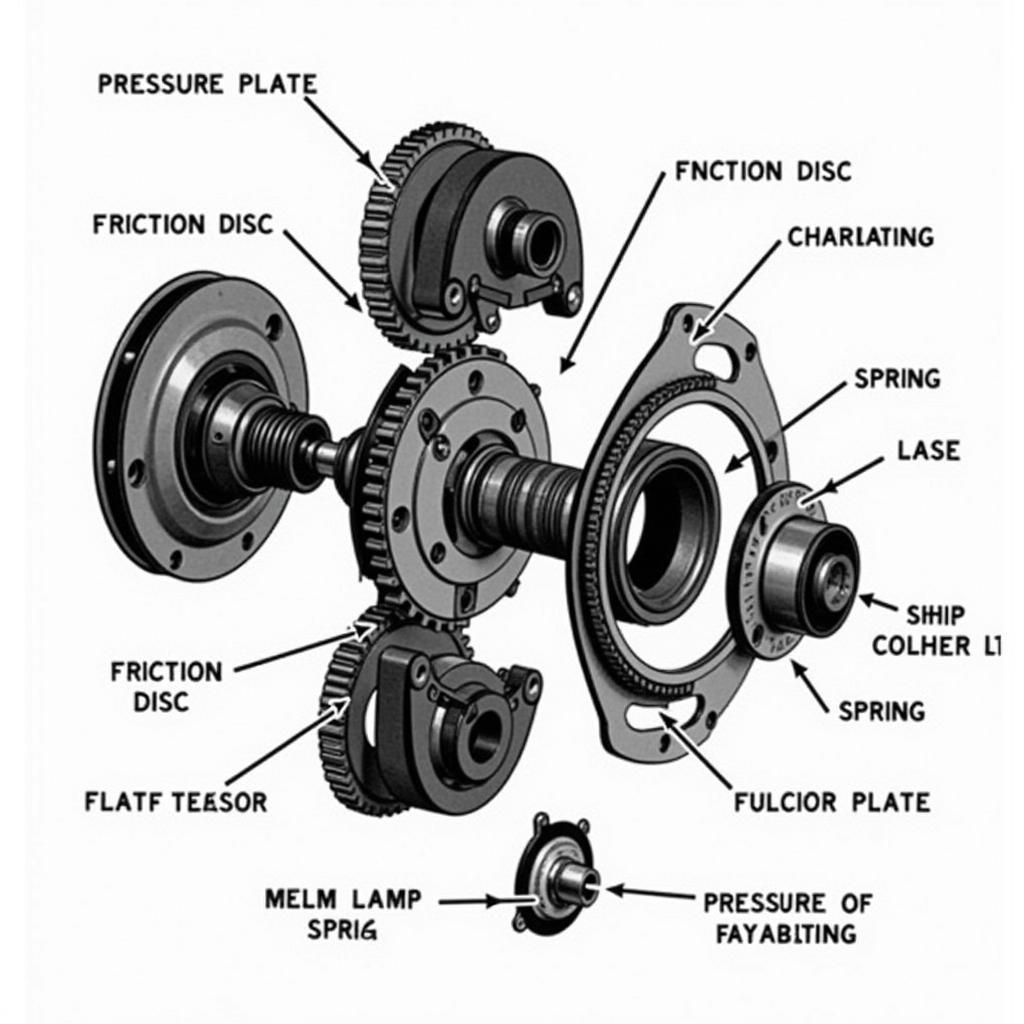

Warner Clutch and Brake Components

Warner Clutch and Brake Components

Understanding Warner Clutches and Brakes

Warner, a leading manufacturer of motion control solutions, offers a diverse range of clutches and brakes designed to meet the demanding requirements of various industries. These components are crucial for controlling motion and torque transmission in a wide array of machinery and vehicles.

How Warner Clutches Work

A clutch is a mechanical device that engages and disengages power transmission between a driving shaft and a driven shaft. Warner clutches utilize various mechanisms, including:

- Friction Clutches: These clutches rely on friction between two or more surfaces to transmit torque. Warner offers a variety of friction clutches, including electromagnetic clutches and mechanical clutches.

- Fluid Clutches: Fluid clutches, also known as hydraulic clutches, utilize fluid coupling to transmit torque. They are often found in heavy-duty applications due to their smooth operation and high torque capacity.

How Warner Brakes Work

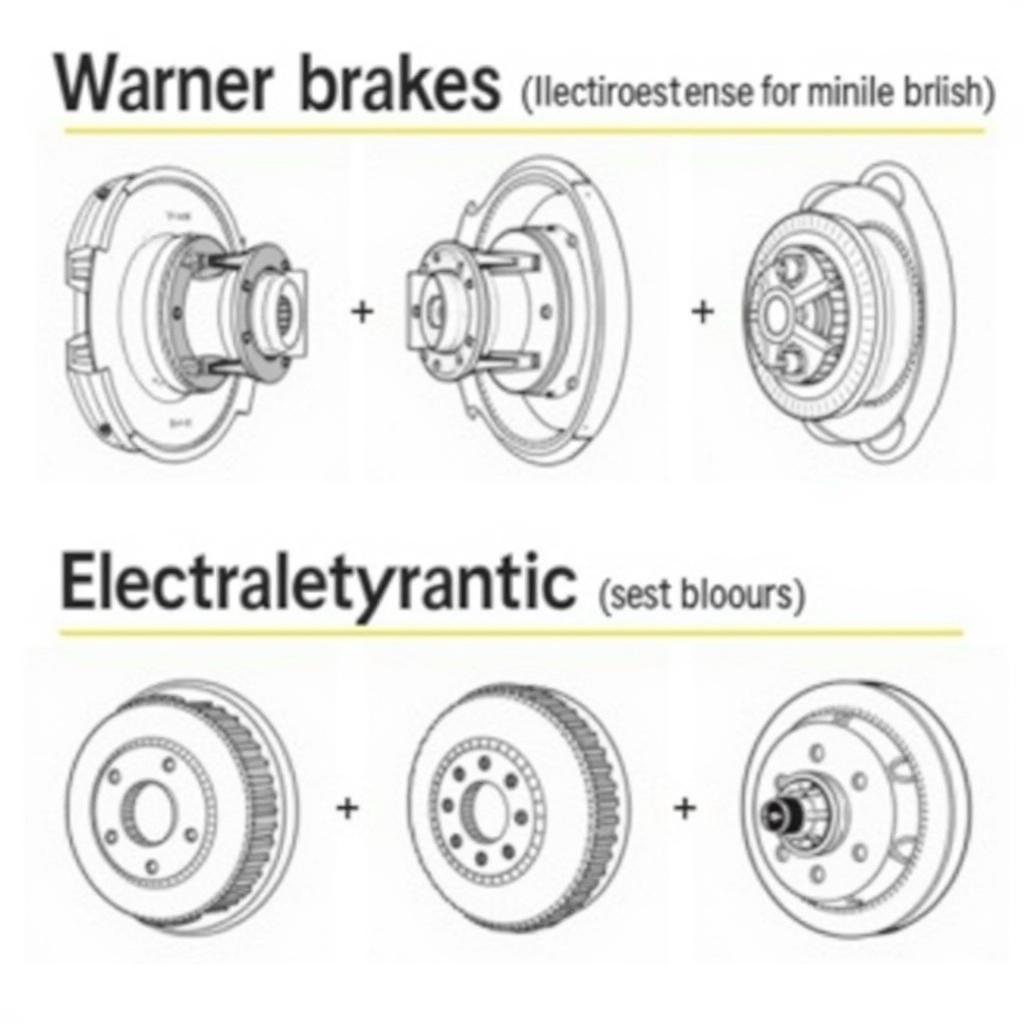

Brakes are designed to slow down or stop the motion of rotating components. Warner brakes employ different principles of operation:

- Friction Brakes: Similar to friction clutches, these brakes use friction between surfaces to generate stopping power. Warner offers a range of friction brakes, including drum brakes and disc brakes.

- Electromagnetic Brakes: These brakes utilize electromagnetic force to engage the braking mechanism, providing precise and reliable stopping power.

Different Types of Warner Brakes

Different Types of Warner Brakes

Applications of Warner Clutches and Brakes

The durability and performance of Warner clutches and brakes make them suitable for a diverse range of applications:

- Automotive: From transmissions and axles to all-wheel drive systems, Warner clutches contribute to smooth gear shifting and power distribution in vehicles.

- Agriculture: Clutches and brakes are essential for agricultural machinery such as tractors, harvesters, and balers, ensuring precise control over various implements.

- Construction: Cranes, excavators, and other construction equipment rely on Warner clutches and brakes for safe and efficient operation in demanding conditions.

- Industrial Machinery: Manufacturing plants utilize Warner clutches and brakes in conveyor systems, packaging machines, and other industrial equipment for precise motion control and automation.

The Advantages of Remote Diagnostics and Software Solutions

In today’s interconnected world, remote diagnostics and software solutions have revolutionized troubleshooting and maintenance in the automotive industry. These technologies offer several advantages when dealing with Warner clutches and brakes:

- Faster Diagnosis: Remote diagnostics allow technicians to quickly identify issues with Warner clutches and brakes without the need for physical inspection, reducing downtime.

- Accurate Troubleshooting: Sophisticated software programs provide technicians with detailed information about the clutch or brake system, enabling accurate diagnosis and repair.

- Software Updates and Calibration: Remote software updates ensure that the clutch or brake system operates at peak performance with the latest software versions and calibrations.

- Reduced Downtime: By utilizing remote diagnostics and software solutions, technicians can address issues promptly, minimizing downtime and keeping vehicles operating efficiently.

warner brakes are known for their reliability and performance in demanding applications.

Common Issues with Warner Clutches and Brakes

While known for durability, Warner clutches and brakes can experience issues over time:

- Wear and Tear: Friction materials in clutches and brakes wear down with use, leading to reduced effectiveness and potential slippage.

- Fluid Leaks: In hydraulic clutches or brakes, fluid leaks can compromise performance and require immediate attention.

- Sensor Malfunctions: Sensors within electronic control systems can fail, affecting clutch engagement and braking performance.

- Software Glitches: As with any electronic system, software glitches can disrupt the normal operation of clutches and brakes.

Remote Diagnostics for Warner Brake Systems

Remote Diagnostics for Warner Brake Systems

Conclusion

Warner clutches and brakes are crucial components in numerous applications, providing reliable motion control and stopping power. Understanding their functionality and utilizing remote diagnostics and software solutions are paramount for efficient troubleshooting and maintenance. By embracing these advancements, technicians can ensure optimal performance, longevity, and safety of vehicles and machinery equipped with Warner clutches and brakes.