The Warner Electric clutch brake is a critical component found in various industrial and commercial vehicles. It plays a vital role in smoothly engaging and disengaging power transmission, impacting the vehicle’s overall performance and safety. This comprehensive guide dives deep into the intricacies of the Warner Electric clutch brake, exploring its functionality, common issues, troubleshooting techniques, and maintenance best practices.

What is a Warner Electric Clutch Brake?

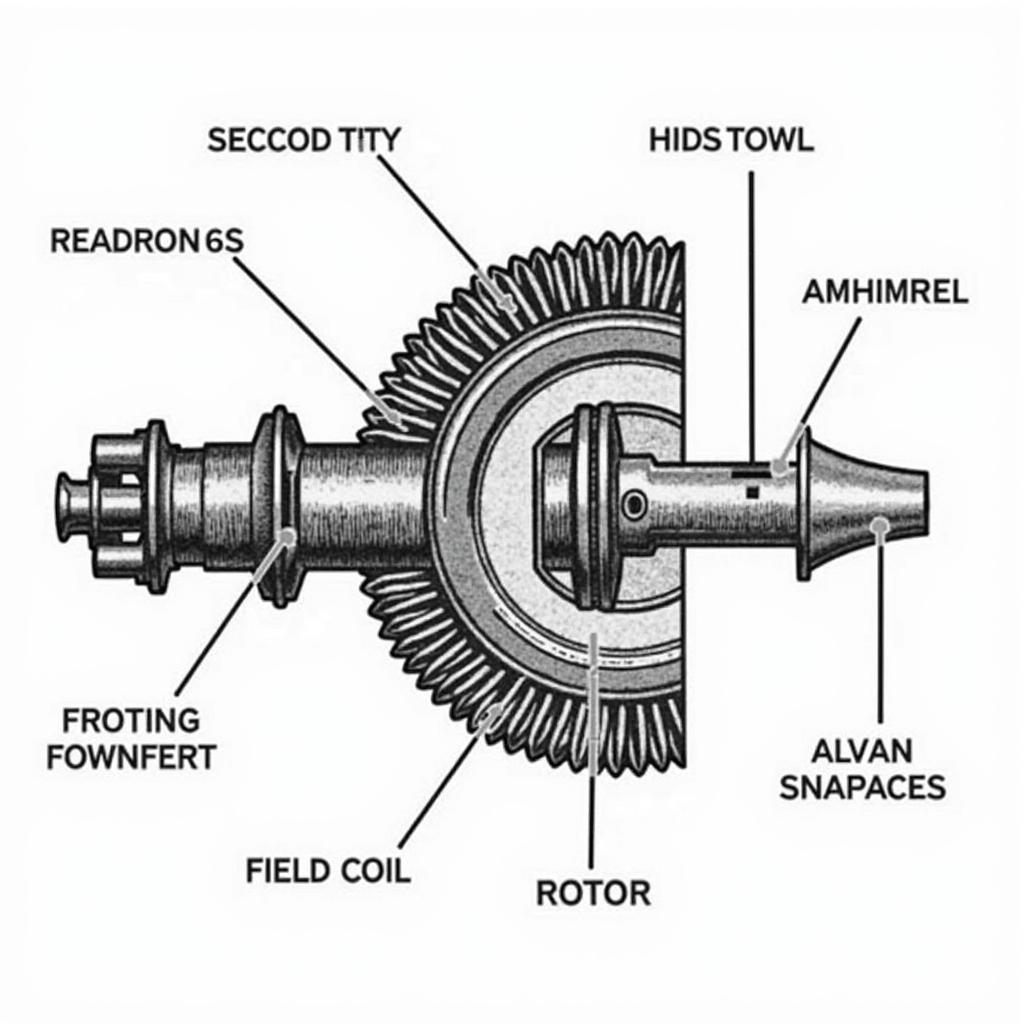

Warner Electric Clutch Brake Components

Warner Electric Clutch Brake Components

The Warner Electric clutch brake is an electromagnetic device that uses an electric current to control the engagement and disengagement of a mechanical clutch or brake. Unlike traditional mechanically actuated systems, this clutch brake operates through the generation of a magnetic field. When energized, this magnetic field attracts a rotor to the clutch or brake surface, effectively transmitting or halting power as needed.

Types of Warner Electric Clutch Brakes

Warner Electric offers a diverse range of clutch brake solutions tailored to meet various application requirements. These include:

- Power-On Clutches & Brakes: These are engaged when energized and disengaged when de-energized. They are commonly used in applications requiring quick and precise engagement, such as packaging machinery and printing presses.

- Power-Off Clutches & Brakes: These operate in the opposite manner, engaging when de-energized and disengaging when energized. They are often found in applications needing a failsafe mechanism, like holding brakes.

- Tooth Clutches & Brakes: These offer high-torque capacity and precision indexing capabilities, making them ideal for robotics and automation systems.

Common Issues and Troubleshooting

Despite their robust design and reliability, Warner Electric clutch brakes can encounter issues over time. Here are some common problems and potential solutions:

1. Clutch Slippage

- Symptom: The clutch fails to transmit the full amount of torque, resulting in a loss of power or reduced speed.

- Possible Causes: Worn friction surfaces, insufficient air gap, low voltage to the clutch coil.

- Troubleshooting: Inspect the friction surfaces for wear and tear, adjust the air gap according to the manufacturer’s specifications, and verify the voltage supply to the clutch coil.

Worn Clutch Brake Friction Surfaces

Worn Clutch Brake Friction Surfaces

2. Brake Drag

- Symptom: The brake fails to disengage completely, causing the machinery to operate sluggishly or overheat.

- Possible Causes: Improper adjustment, sticking armature, worn bearings.

- Troubleshooting: Check and adjust the brake air gap, inspect the armature for signs of sticking or binding, and replace worn bearings as needed.

3. Noisy Operation

- Symptom: Unusual noises like grinding, screeching, or squealing during engagement or disengagement.

- Possible Causes: Misalignment, worn components, lubrication issues.

- Troubleshooting: Ensure proper alignment of the clutch or brake assembly, inspect and replace worn components, and lubricate moving parts according to the manufacturer’s recommendations.

4. Overheating

- Symptom: Excessive heat generation during operation, leading to reduced performance or potential damage.

- Possible Causes: Continuous slipping, inadequate cooling, improper voltage supply.

- Troubleshooting: Identify and address the root cause of slipping, ensure sufficient cooling for the application, and verify the voltage supplied to the clutch or brake coil.

Remote Diagnostics and Software Solutions

warner electric brake clutch co has been at the forefront of integrating technology into its products. Remote diagnostics and software solutions are now available for some Warner Electric clutch brake systems. These advanced tools enable technicians to:

- Real-time Data Monitoring: Monitor critical parameters such as current, temperature, and engagement time remotely to diagnose issues proactively.

- Fault Code Analysis: Quickly identify and interpret fault codes to pinpoint the root cause of malfunctions.

- Software Updates and Parameter Adjustments: Perform firmware updates and adjust operational parameters remotely to optimize performance and resolve issues.

These technological advancements streamline the troubleshooting process, minimize downtime, and improve overall efficiency for businesses utilizing Warner Electric clutch brake systems.

Maintenance Best Practices

Regular maintenance is crucial to maximize the lifespan and ensure the optimal performance of Warner Electric clutch brakes. Here are some essential maintenance practices:

- Inspection: Regularly inspect the clutch or brake assembly for signs of wear and tear, including the friction surfaces, armature, bearings, and electrical connections.

- Cleaning: Keep the clutch or brake assembly clean and free from debris, dirt, and contaminants to prevent premature wear and malfunctions.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to reduce friction and ensure smooth operation.

- Adjustment: Periodically adjust the air gap and other critical parameters according to the manufacturer’s specifications to maintain optimal performance.

- Professional Service: Consult a qualified technician for complex repairs or if you encounter issues beyond your expertise.

Choosing the Right Warner Electric Clutch Brake

Selecting the appropriate Warner Electric clutch brake is crucial for ensuring optimal performance and longevity. Here are some factors to consider:

- Torque Requirements: Determine the required torque capacity for your application to ensure the clutch or brake can handle the load.

- Speed: Consider the operational speed of your machinery to choose a clutch or brake that can operate effectively within the desired range.

- Duty Cycle: Evaluate the frequency and duration of clutch or brake engagement to determine the required duty cycle rating.

- Environmental Conditions: Factor in the operating environment, including temperature, humidity, and exposure to contaminants, to select a clutch or brake with suitable environmental protection.

- Mounting Options: Consider the available mounting space and requirements to choose a clutch or brake with compatible mounting options.

Conclusion

The Warner Electric clutch brake is a versatile and reliable component that plays a critical role in a wide range of industrial and commercial applications. Understanding its functionality, common issues, and troubleshooting techniques is essential for ensuring smooth operation, minimizing downtime, and maximizing the lifespan of your machinery. By following recommended maintenance practices and leveraging advancements in remote diagnostics and software solutions, you can ensure optimal performance and longevity for your Warner Electric clutch brake system.

bulk yj.6fy warner electric brake clutch are commonly found in industrial equipment.

FAQs

1. How long does a Warner Electric clutch brake typically last?

The lifespan of a Warner Electric clutch brake varies depending on factors such as usage, load, maintenance, and operating environment. However, with proper care and maintenance, they can last for several years or even decades.

2. Can I repair a Warner Electric clutch brake myself?

While some basic maintenance tasks can be performed by users, it’s generally recommended to consult a qualified technician for complex repairs or if you encounter issues beyond your expertise.

3. What are the advantages of using a Warner Electric clutch brake over a mechanically actuated system?

Warner Electric clutch brakes offer several advantages, including faster response times, greater control and precision, reduced wear and tear on associated components, and enhanced safety features.

4. How can I prevent overheating in my Warner Electric clutch brake?

Ensure the clutch or brake is appropriately sized for the application, avoid continuous slipping, provide adequate cooling, and maintain the correct voltage supply.

5. Where can I find technical documentation and support for my Warner Electric clutch brake?

You can access technical documentation, support resources, and contact information for Warner Electric through their official website or authorized distributors.