The brake pressure warning light on your 2002 International 4900 is a critical safety feature that alerts you to potential problems within your air brake system. Ignoring this warning light could lead to reduced braking power and dangerous driving conditions. This comprehensive guide will delve into the common causes of a lit brake pressure warning light in your International 4900 and provide practical solutions for diagnosis and repair.

Understanding Your Air Brake System

Before diving into troubleshooting, it’s essential to grasp the basics of how your International 4900’s air brake system operates. Unlike hydraulic systems found in passenger vehicles, air brakes rely on compressed air to engage the brakes. The system comprises several key components:

- Air Compressor: This component generates the pressurized air needed for braking.

- Air Dryer: This unit removes moisture from the compressed air, preventing corrosion and freezing within the system.

- Air Tanks: These reservoirs store the compressed air.

- Brake Valves: These valves control the flow of air pressure to the brakes.

- Brake Chambers: Located at each wheel, these chambers use air pressure to push the brake shoes or pads against the drums or rotors, respectively.

Common Causes of a Lit Brake Pressure Warning Light

A lit brake pressure warning light usually indicates a loss of air pressure within the system. Here are the most common culprits:

1. Air Leaks

- Loose Fittings: Check all air lines and fittings for any signs of looseness or damage.

- Worn Hoses: Over time, air hoses can deteriorate, leading to leaks. Inspect hoses for cracks, bulges, or abrasions.

- Faulty Air Dryer: A malfunctioning air dryer can allow moisture to enter the system, corroding components and causing leaks.

Air Brake System Leak

Air Brake System Leak

2. Compressor Issues

- W Worn Compressor: A worn-out compressor may not generate sufficient air pressure. Listen for unusual noises from the compressor, which could indicate wear.

- Faulty Compressor Governor: The governor regulates air pressure. A malfunctioning governor can lead to overcharging or undercharging the system.

3. Brake Valve Problems

- Malfunctioning Valves: Brake valves control the flow of air to the brakes. A sticking or leaking valve can disrupt system pressure.

- Electrical Issues: Electrical problems with the valve solenoids or wiring can also prevent proper valve operation.

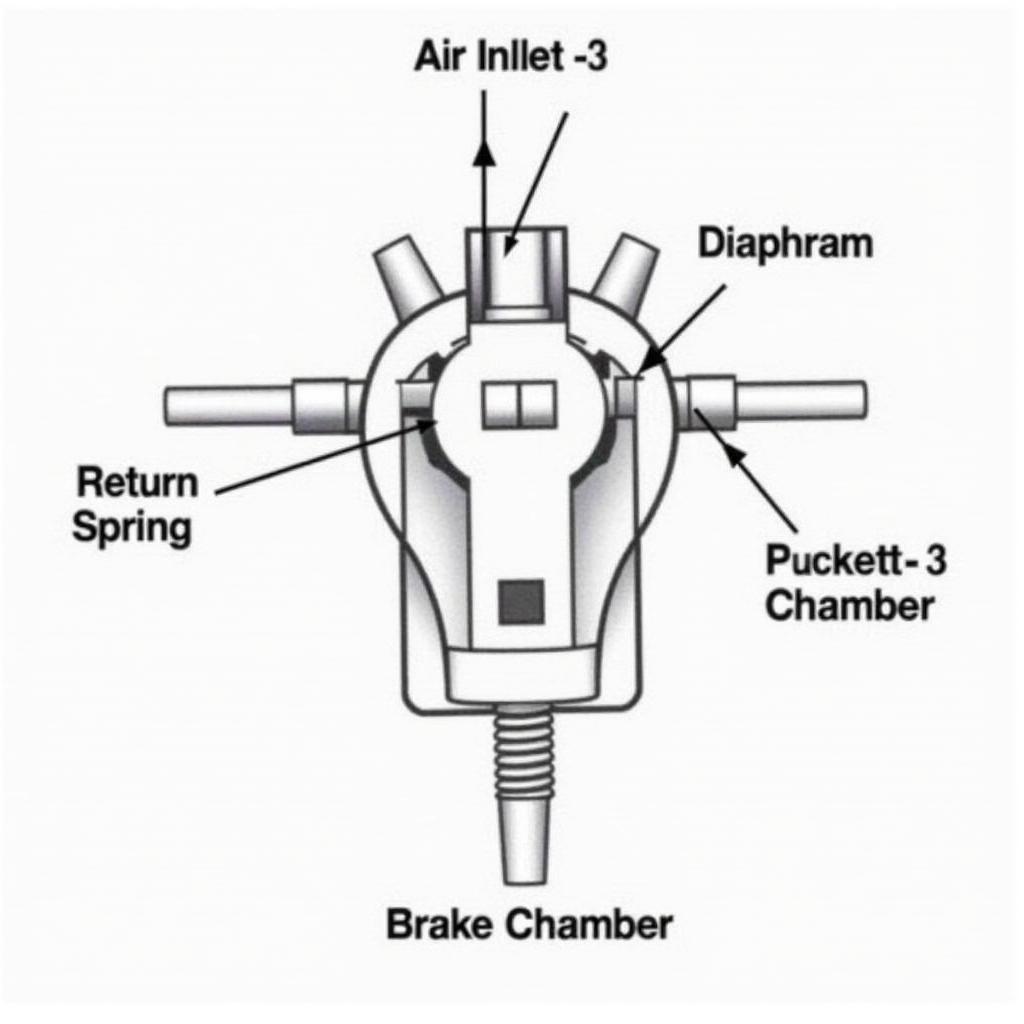

4. Brake Chamber Issues

- Leaking Chamber: A damaged or worn-out brake chamber can lead to air loss and reduced braking force.

- Stuck Brake Shoes: Seized brake shoes can prevent the brake chamber from properly releasing air pressure.

Brake Chamber Components

Brake Chamber Components

Diagnosing the Problem

- Check Air Pressure Gauge: Your International 4900’s dashboard gauge will show the current air pressure level. Low pressure confirms a leak or compressor issue.

- Listen for Leaks: With the engine running, carefully listen for hissing sounds near air lines, fittings, and components.

- Apply Soap Solution: A mixture of soap and water applied to suspected leak points can help pinpoint their location by forming bubbles.

- Inspect Air Dryer Purge Valve: A constantly purging air dryer valve indicates a problem with the dryer itself or a persistent air leak.

“When diagnosing air brake issues, prioritize safety,” advises veteran truck mechanic, John Riley. “Always chock the wheels and release air pressure from the system before working on any components.”

Resolving Brake Pressure Warning Light Issues

For Air Leaks:

- Tighten Loose Fittings: Using a wrench, carefully tighten any loose air line fittings.

- Replace Damaged Hoses: If you find cracked or damaged air hoses, replace them immediately. Ensure the new hoses are the correct size and pressure rating.

- Repair or Replace Faulty Components: For leaks originating from components like the air dryer or brake valves, repair or replacement might be necessary.

For Compressor Problems:

- Inspect and Clean Air Intake: A clogged air intake can restrict airflow to the compressor, reducing its efficiency.

- Test Compressor Governor: A mechanic can test the compressor governor to ensure it’s functioning correctly.

- Rebuild or Replace Compressor: If the compressor is worn out or damaged, rebuilding or replacement might be the only option.

For Brake Valve and Chamber Issues:

- Check for Stuck Valves: Inspect brake valves for signs of sticking or debris that might be hindering their operation.

- Inspect and Test Electrical Components: Verify the functionality of valve solenoids, wiring harnesses, and connections.

- Inspect Brake Chambers: Check for leaks, damage, or seized components within the brake chambers.

Mechanic Inspecting Air Brakes

Mechanic Inspecting Air Brakes

Conclusion

The brake pressure warning light on your 2002 International 4900 should never be ignored. By understanding the common causes behind this warning, you can take the necessary steps to diagnose and address the issue promptly. Remember, a properly functioning air brake system is crucial for your safety and the safety of others on the road. If you’re unsure about any aspect of diagnosing or repairing your truck’s air brake system, consult with a qualified truck mechanic immediately.

FAQ

1. Can I drive my truck with the brake pressure warning light on?

It’s highly discouraged. Driving with a lit brake pressure warning light significantly increases the risk of brake failure.

2. How often should I have my air brake system serviced?

It’s recommended to have your air brake system inspected by a qualified mechanic at least once a year or as specified in your truck’s owner’s manual.

3. How much does it cost to fix a brake pressure warning light issue?

The cost can vary greatly depending on the underlying cause and the necessary repairs.

4. What is the normal air pressure range for my International 4900?

The typical air pressure range is between 100 and 120 PSI.

5. Can I use starting fluid to find air leaks?

No! Starting fluid is extremely flammable and dangerous to use near an air brake system. Stick to a soap and water solution.