A stuck brake on a Warn winch can bring your off-roading adventures to a screeching halt. Whether you’re a seasoned off-roader or a weekend warrior, understanding the common causes and solutions for a stuck Warn winch brake can save you time, frustration, and potentially a costly trip to the mechanic. This guide will walk you through the steps to remotely diagnose and potentially fix the issue using innovative software solutions.

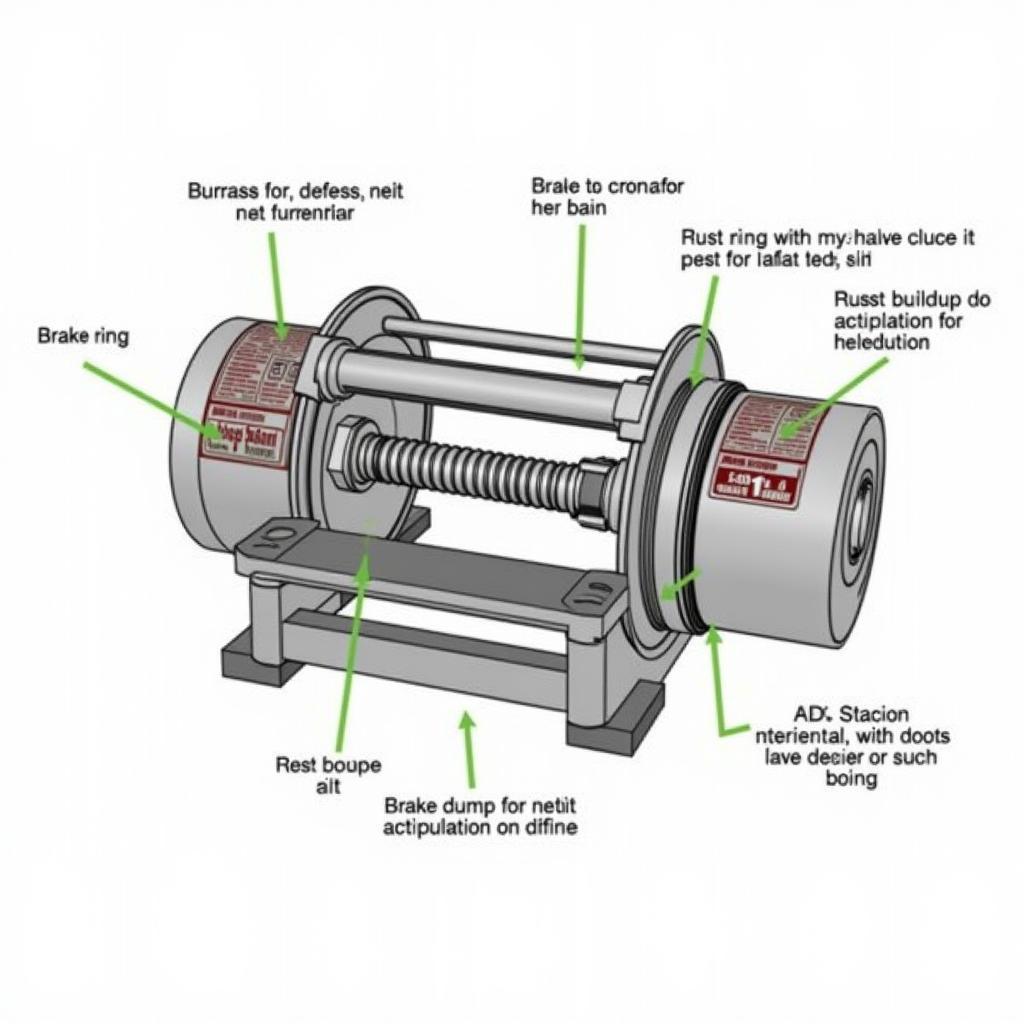

Warn winch brake system components

Warn winch brake system components

Understanding Your Warn Winch Brake

Before diving into troubleshooting, it’s crucial to understand how your Warn winch brake system works. The brake is designed to hold the load securely when the winch is not in use, preventing unwanted spooling and potential danger. Most Warn winches utilize an automatic mechanical brake system that engages when the winch motor is not powered.

Here’s a simplified breakdown:

- Brake Ring: This component makes direct contact with the brake drum, creating friction to stop and hold the load.

- Brake Drum: Attached to the winch drum, this component houses the brake ring and provides the necessary surface for braking.

- Activation Mechanism: Typically a spring-loaded system that applies pressure to the brake ring, engaging the brake when the winch motor is off.

Common Causes of a Stuck Warn Winch Brake

A stuck brake can stem from several factors, often related to wear and tear, lack of maintenance, or environmental factors:

- Rust and Corrosion: Exposure to moisture, especially in coastal or humid environments, can lead to rust buildup on the brake ring, drum, or activation mechanism, hindering movement.

- Dirt and Debris: Mud, sand, and other debris can accumulate within the brake system, interfering with the brake ring’s ability to move freely.

- Lack of Lubrication: Insufficient lubrication on moving parts within the brake system can create excessive friction, leading to a stuck brake.

- Cable Overwrap: Incorrectly spooling the winch cable can jam the mechanism, putting pressure on the brake and preventing release.

- Worn Brake Components: Over time, the brake ring, springs, or other components can wear down, leading to malfunctions.

Remote Diagnostics for Warn Winch Brake Issues

Advances in automotive technology now allow for remote diagnostics of many vehicle systems, including winches. Utilizing specialized software and diagnostic tools, experienced technicians can connect to your vehicle remotely to:

- Read Fault Codes: Retrieve diagnostic trouble codes (DTCs) stored in your vehicle’s electronic control unit (ECU) related to the winch system.

- Monitor Live Data: Analyze real-time data streams from various sensors within the winch system, such as voltage, current, and motor speed, to pinpoint anomalies.

- Perform Actuator Tests: Remotely engage and disengage the winch motor and brake system to assess functionality and identify potential sticking points.

Technician using remote diagnostics software for a Warn winch

Technician using remote diagnostics software for a Warn winch

Steps to Troubleshoot a Stuck Warn Winch Brake Remotely

While a remote diagnosis from a qualified technician is recommended for accurate troubleshooting, here are some general steps they might take:

-

Connect to the Vehicle: Using specialized software and hardware, the technician establishes a secure connection to your vehicle’s onboard diagnostics port (OBD-II).

-

Retrieve Fault Codes: The technician scans for and retrieves any stored DTCs related to the winch system, providing valuable clues about the potential cause of the stuck brake.

-

Analyze Live Data: By monitoring live data streams from the winch system, the technician can identify irregularities in voltage, current, or other parameters that might indicate a stuck brake.

-

Perform Actuator Tests: The technician remotely engages and disengages the winch motor and brake to assess functionality. Observing the system’s response during these tests can help pinpoint the source of the problem.

-

Interpret Results and Recommend Solutions: Based on the information gathered, the technician can provide a diagnosis and recommend solutions. This might involve simple adjustments, lubrication, or replacement of specific components.

When to Seek Professional Help

While remote diagnostics can be incredibly helpful, certain situations might require hands-on inspection and repair by a qualified technician:

-

Physical Damage: If the stuck brake is due to physical damage to the winch, such as a bent shaft or damaged housing, a physical inspection and repair will be necessary. For guidance on brake shaft removal, refer to our guide on warn 8274 brake shaft removal.

-

Internal Component Failure: Internal issues within the winch motor or gearbox typically require specialized tools and expertise for disassembly and repair.

-

Software or Electrical Problems: Complex electrical or software-related problems might necessitate advanced diagnostic equipment and knowledge to resolve.

Conclusion

A stuck Warn winch brake can be a frustrating experience, but with the advent of remote diagnostics, troubleshooting and resolving the issue has become more accessible. Understanding how your winch brake works, recognizing common causes of problems, and utilizing remote diagnostics can save you time and money. Remember, always consult a qualified technician for any complex repairs or if you’re unsure about performing any maintenance yourself.