Warner Electric brake distributors are essential components in many commercial vehicles, playing a crucial role in ensuring safe and reliable braking performance. These sophisticated systems use electrical signals to control the air pressure applied to each wheel’s brake chamber, ensuring optimal braking force distribution and preventing wheel lock-up.

While Warner Electric brake distributors are renowned for their durability and reliability, like any other mechanical or electrical system, they can experience issues over time. Recognizing the symptoms of a failing brake distributor and understanding the common problems associated with them can be invaluable for fleet managers, technicians, and drivers alike. This comprehensive guide will delve into the intricacies of Warner Electric brake distributors, common issues, troubleshooting tips, and available solutions to help you maintain optimal braking performance and ensure safety on the road.

Common Issues with Warner Electric Brake Distributors:

Several factors can contribute to problems with Warner Electric brake distributors. Identifying the root cause of the issue is crucial for effective troubleshooting and repair. Here are some of the most common problems encountered:

-

Electrical Faults: Wiring harnesses and connectors can become damaged or corroded due to exposure to harsh environments, leading to intermittent connections or complete circuit failures. Malfunctioning sensors, such as the brake light switch or ABS wheel speed sensors, can also disrupt the electrical signals sent to the brake distributor.

-

Air Leaks: Air leaks within the brake distributor or its associated components, such as the air compressor, air lines, or brake chambers, can result in reduced braking efficiency and longer stopping distances. Leaks can occur due to worn-out seals, damaged components, or loose connections.

-

Internal Component Failure: Over time, the internal components of a brake distributor, such as valves, diaphragms, and springs, can wear out or break down, leading to malfunction. These failures can manifest as uneven braking, reduced braking force, or complete brake system failure.

-

Software or Programming Errors: Modern Warner Electric brake distributors incorporate electronic control units (ECUs) that rely on software for proper operation. Software bugs, corrupted data, or incompatible software versions can disrupt the brake distributor’s functionality and lead to various braking issues.

Diagnosing Warner Electric Brake Distributor Problems:

Accurate diagnosis is paramount for efficiently resolving brake distributor issues. Employing a systematic approach that combines visual inspection, diagnostic tools, and symptom analysis can help pinpoint the root cause:

-

Visual Inspection: Begin by visually inspecting the brake distributor and its associated components. Look for any signs of physical damage, corrosion, loose connections, or air leaks. Pay close attention to the wiring harness, connectors, air lines, and the brake distributor housing itself.

-

Diagnostic Scanning: Modern vehicles equipped with Warner Electric brake distributors often feature onboard diagnostic systems. Connecting a compatible scan tool to the vehicle’s OBD-II port allows you to retrieve diagnostic trouble codes (DTCs) stored in the brake distributor’s ECU. These codes provide valuable insights into the specific areas experiencing faults, streamlining the troubleshooting process.

-

Pressure Testing: Air leaks are common culprits behind brake distributor problems. Using a specialized air pressure gauge and testing kit, check for leaks within the brake distributor, air lines, and brake chambers. Listen for hissing sounds or observe pressure drops that indicate the presence of leaks.

-

Component Testing: If the visual inspection, diagnostic scanning, and pressure testing don’t reveal the issue, individual component testing may be necessary. This involves testing the functionality of sensors, valves, solenoids, and other electrical components using a multimeter or other specialized tools.

Solutions and Repair Options:

Once the root cause of the brake distributor problem has been identified, the appropriate repair or replacement steps can be taken:

-

Electrical Repairs: Addressing electrical faults may involve repairing or replacing damaged wiring harnesses, cleaning or replacing corroded connectors, or replacing faulty sensors. Ensure all electrical connections are secure and free from corrosion to prevent intermittent issues.

-

Air Leak Repair: Repairing air leaks typically involves replacing worn-out seals, tightening loose connections, or replacing damaged air lines or brake chambers. After completing any air system repairs, it’s crucial to conduct a thorough pressure test to ensure all leaks have been addressed.

-

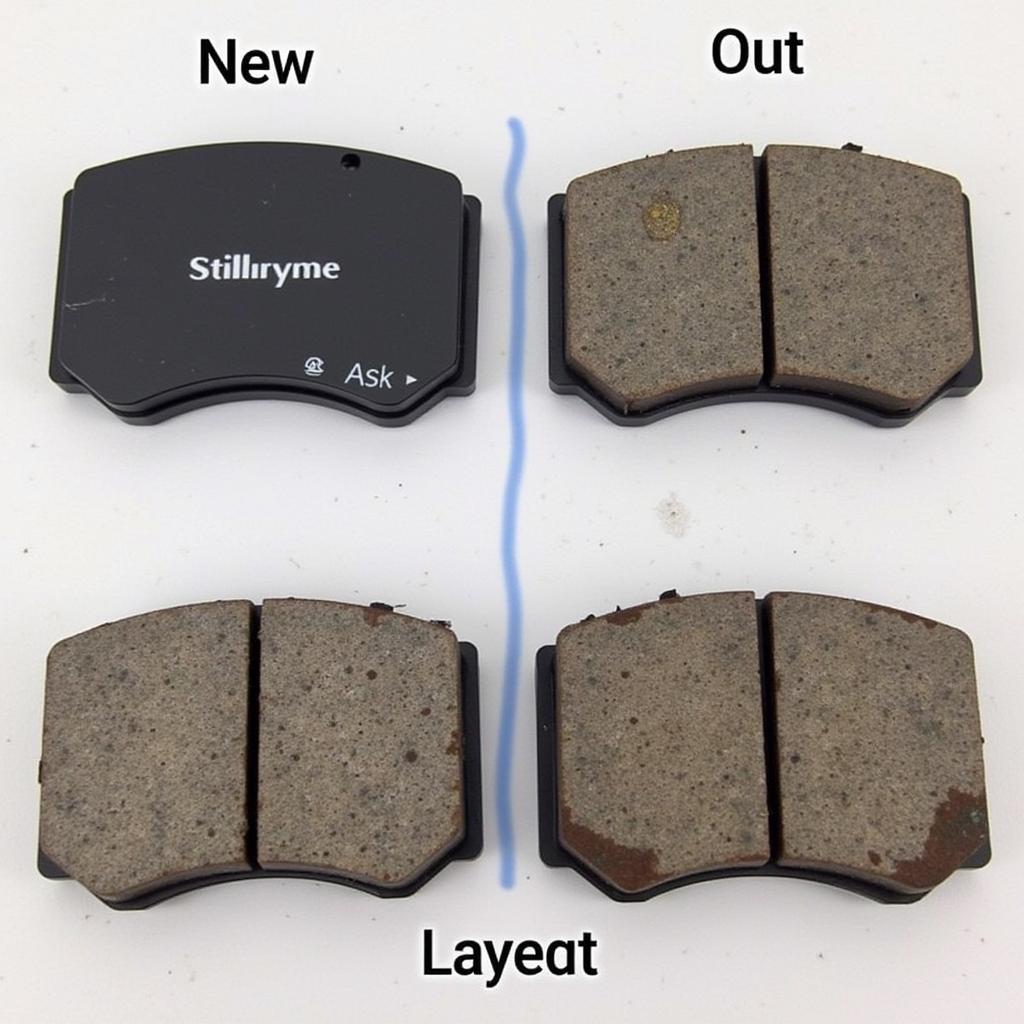

Component Replacement: Worn-out or broken internal components often necessitate replacement. This may involve replacing valves, diaphragms, springs, or other internal parts. In some cases, rebuilding the brake distributor with new components may be a cost-effective solution compared to complete replacement.

-

Software Updates and Reprogramming: Software-related issues may require updating the brake distributor’s ECU software to the latest version. Reprogramming the ECU with the correct parameters and configurations for the specific vehicle application is essential for optimal performance and compatibility.

Remote Diagnostics and Programming:

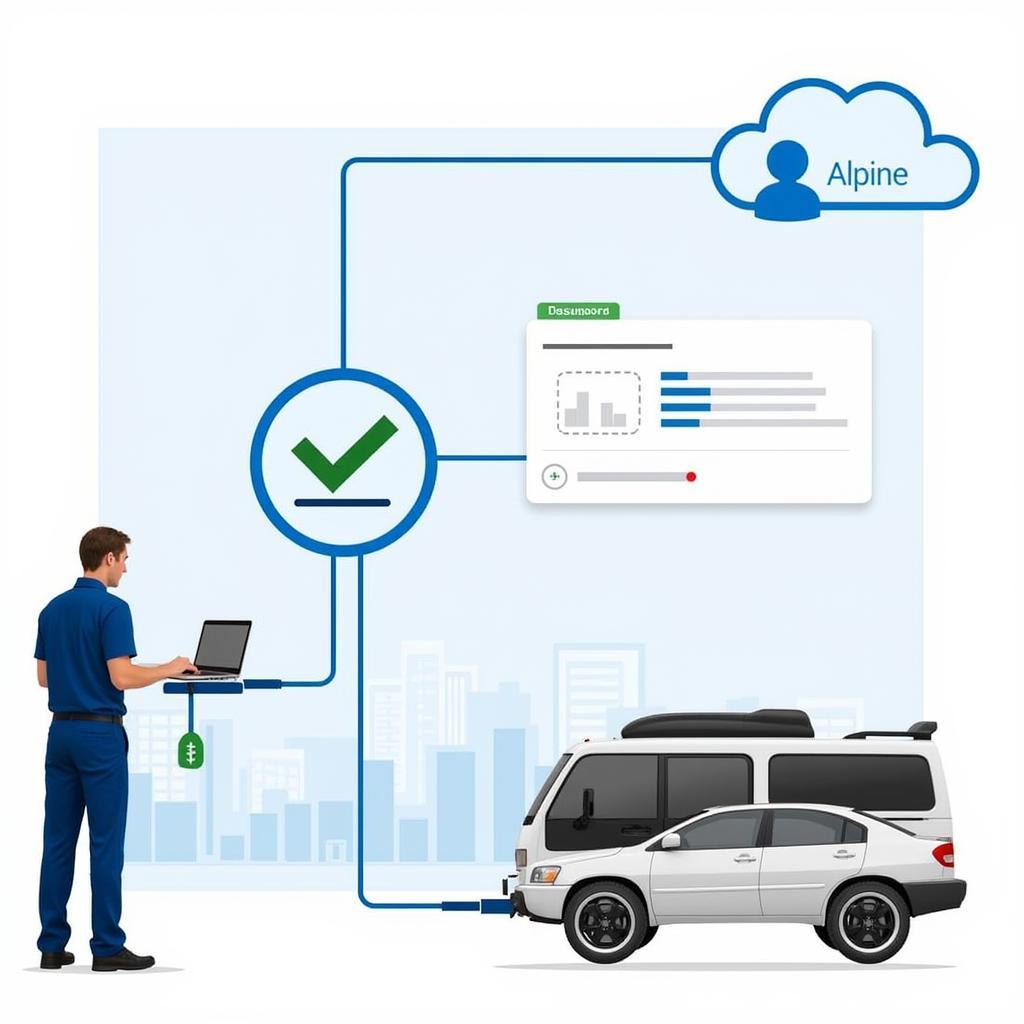

Advancements in automotive technology have paved the way for remote diagnostics and programming of Warner Electric brake distributors. This cutting-edge capability enables technicians to access and troubleshoot brake systems remotely, minimizing downtime and reducing repair costs.

Through specialized software and a secure internet connection, technicians can perform the following tasks remotely:

-

Remote Diagnostics: Retrieve diagnostic trouble codes, monitor real-time sensor data, and analyze system performance to diagnose issues accurately.

-

Software Updates and Calibration: Upload and install the latest software updates to the brake distributor’s ECU to enhance functionality, address known issues, and ensure optimal compatibility.

-

Parameter Adjustments and Configuration: Fine-tune various brake system parameters, such as brake pressure modulation and ABS sensitivity, remotely to optimize performance based on specific vehicle usage and operating conditions.

Conclusion:

Warner Electric brake distributors are critical components in ensuring reliable braking performance in commercial vehicles. Understanding the common problems, troubleshooting steps, and available solutions can help fleet managers, technicians, and drivers maintain optimal brake system health. By embracing proactive maintenance practices and leveraging advancements in remote diagnostics and programming, you can minimize downtime, reduce repair costs, and most importantly, ensure the safety of your vehicles and drivers on the road. If you’re experiencing issues with your Warner Electric brake distributor, it’s crucial to consult with a qualified technician to diagnose and repair the problem promptly, restoring your vehicle’s braking system to its optimal operating condition.

FAQs:

Q: How often should I have my Warner Electric brake distributor inspected?

A: It’s recommended to have your brake distributor inspected annually or every 100,000 miles, whichever comes first, as part of your vehicle’s regular maintenance schedule.

Q: Can I drive my vehicle with a faulty brake distributor?

A: No, it’s extremely dangerous to operate a vehicle with a faulty brake distributor. A malfunctioning brake distributor can lead to reduced braking performance or complete brake failure, putting you and others at risk.

Q: What is the average lifespan of a Warner Electric brake distributor?

A: The lifespan of a brake distributor varies depending on factors like driving conditions, maintenance, and vehicle usage. However, with proper care, they can last for several years or hundreds of thousands of miles.

Q: Are there any warning signs of a failing brake distributor?

A: Yes, common warning signs include illuminated brake warning lights, longer stopping distances, uneven braking, pulling to one side while braking, and unusual noises coming from the brake system.

Q: Can I replace a Warner Electric brake distributor myself?

A: While it’s technically possible to replace a brake distributor yourself, it’s a complex procedure that requires specialized tools, knowledge, and experience. It’s highly recommended to have this repair performed by a qualified technician to ensure it’s done correctly and safely.

Q: What are the benefits of remote diagnostics and programming for brake distributors?

A: Remote diagnostics and programming offer numerous advantages, including reduced downtime, lower repair costs, faster diagnosis, access to specialized expertise, and proactive maintenance capabilities.

Q: How can I find a qualified technician to service my Warner Electric brake distributor?

A: You can search online for certified truck mechanics or automotive repair shops specializing in commercial vehicle brake systems. Additionally, you can contact your vehicle manufacturer or dealer for recommendations on authorized service centers.

This article provides general information and should not be considered a substitute for professional advice from a qualified technician. Always consult with a qualified mechanic for any brake system repairs or maintenance needs.