Power Warner electric brakes utilizing Pulse Width Modulation (PWM) offer a sophisticated solution for trailer braking systems. Unlike traditional electric brakes that rely on constant voltage, PWM systems deliver controlled pulses of electricity, resulting in smoother braking, enhanced control, and improved performance. This article will delve into the intricacies of Power Warner electric brakes with PWM, exploring their functionality, benefits, and troubleshooting tips for optimal braking performance.

How Power Warner Electric Brakes with PWM Work

At the heart of the system lies the PWM controller, responsible for regulating the electrical pulses sent to the brake magnets. Instead of a continuous flow of electricity, the controller generates pulses of varying widths (duration). The width of these pulses determines the strength of the magnetic field generated, and consequently, the braking force applied.

When you apply the trailer brakes, the PWM controller sends a signal to the brake magnets. A wider pulse width corresponds to a stronger magnetic field, resulting in greater braking force. Conversely, a narrower pulse width weakens the magnetic field, reducing the braking force. This dynamic adjustment of pulse widths allows for precise control over the trailer’s deceleration, ensuring a smooth and controlled stop.

Advantages of Power Warner Electric Brakes with PWM

The integration of PWM technology into Power Warner electric brakes brings forth a range of advantages over conventional braking systems. Let’s explore some key benefits:

Enhanced Braking Control and Smoothness

PWM technology enables extremely precise control over the braking force applied to the trailer. By fine-tuning the pulse width, the system can achieve gradual and seamless braking, minimizing jerky movements and providing a more comfortable ride for both the driver and the load being towed.

“The beauty of PWM lies in its ability to deliver smooth, proportional braking,” says John Miller, a seasoned automotive electrical engineer with over 20 years of experience. “This translates to a safer and more controlled towing experience, especially in challenging conditions.”

Increased Efficiency and Reduced Heat Generation

Traditional electric brakes often generate excessive heat due to the constant flow of electricity, leading to reduced performance and potential component wear. PWM systems address this issue by delivering short bursts of electricity, minimizing heat buildup and maximizing efficiency.

Extended Brake Life and Reduced Wear

The controlled application of braking force through PWM minimizes wear and tear on the brake components. Since the system applies only the necessary amount of force, the brake shoes and drums experience less friction, extending their lifespan and reducing maintenance requirements.

Troubleshooting Power Warner Electric Brakes with PWM

While Power Warner electric brakes with PWM are generally reliable, occasional issues may arise. Here are some common problems and troubleshooting tips:

1. No Trailer Brakes:

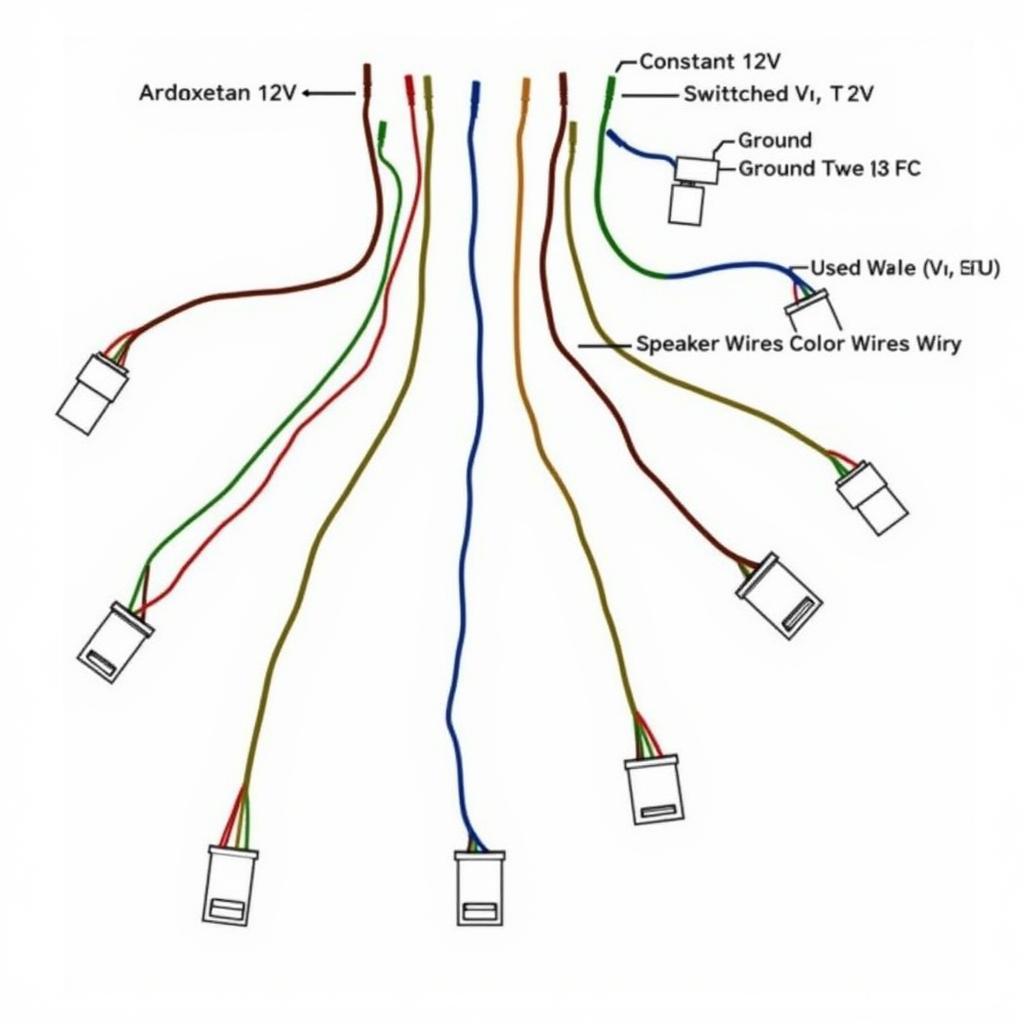

- Check the connections: Ensure all wiring connections between the controller, battery, and brake magnets are secure and free from corrosion.

- Test the brake controller: Use a voltmeter to check for power output from the controller when the brake pedal is depressed.

- Inspect the breakaway switch: Verify that the breakaway switch is properly connected and functioning correctly.

2. Trailer Brakes Lock Up:

- Adjust the gain setting: Lower the gain setting on the brake controller to reduce the initial braking force applied.

- Check for shorts in the wiring: Inspect the wiring harness for any signs of damage, pinching, or exposed wires that could cause a short circuit.

3. Uneven Braking:

- Inspect brake shoes and drums: Ensure that the brake shoes are properly adjusted and that the drums are free from excessive wear or damage.

- Clean the brake assemblies: Dirt and debris buildup can interfere with proper brake operation.

4. Intermittent Braking Issues:

- Check the ground connection: Ensure the ground wire from the controller to the vehicle chassis has a clean and secure connection.

- Inspect the trailer connector: Look for any signs of damage or corrosion that could be causing intermittent connections.

Conclusion

Power Warner electric brakes with PWM represent a significant advancement in trailer braking technology. Their ability to deliver smooth, controlled, and efficient braking enhances safety and performance while minimizing wear and tear on the braking system. By understanding the workings of these systems and following the provided troubleshooting tips, you can ensure optimal braking performance and enjoy a safer, more controlled towing experience. Remember, regular maintenance and prompt attention to any arising issues will contribute significantly to the longevity and reliability of your trailer’s braking system.