The Warner clutch brake coupling is a critical component found in various industrial and automotive applications. It ensures seamless power transmission and precise control, contributing significantly to the overall performance and safety of the machinery it powers. This comprehensive guide delves into the intricacies of this remarkable device, exploring its functionality, applications, common issues, and troubleshooting techniques.

How a Warner Clutch Brake Coupling Works

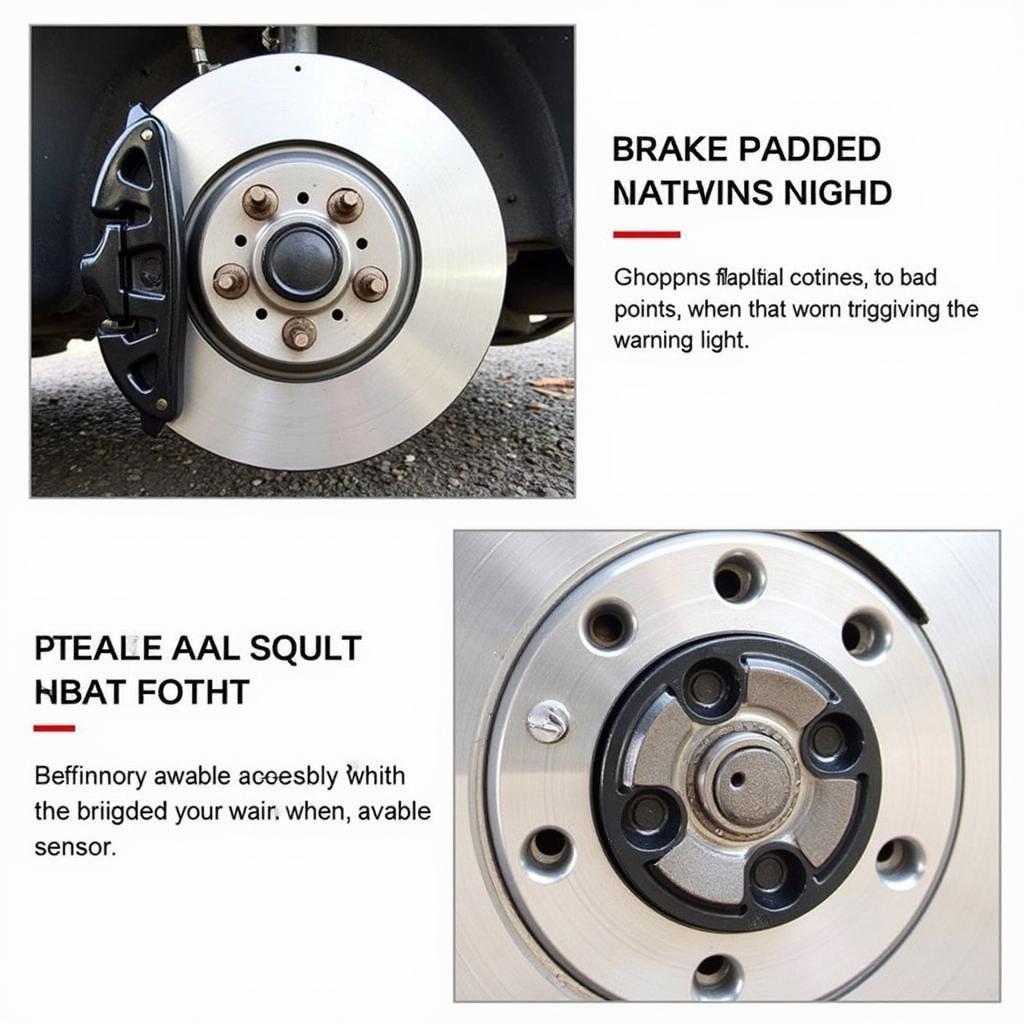

A Warner clutch brake coupling is essentially a combination of two mechanisms: a clutch and a brake, integrated into a single unit. This ingenious design allows for controlled engagement and disengagement of power transmission from a driving shaft to a driven shaft.

Here’s a breakdown of the process:

- Clutch Engagement: When the clutch is engaged, it transmits power from the input shaft to the output shaft. This engagement can be achieved through various means, depending on the type of clutch used, such as electromagnetic, hydraulic, or pneumatic actuation.

- Clutch Disengagement: When the clutch is disengaged, it interrupts the power flow between the shafts, effectively decoupling the driven load from the driving source. This feature is crucial for preventing damage during overloads or emergency stops.

- Brake Activation: Simultaneously, the brake mechanism can be activated to bring the output shaft to a controlled stop. This integrated braking function eliminates the need for separate braking systems, simplifying the overall design and enhancing operational efficiency.

Applications of Warner Clutch Brake Couplings

The versatility of Warner clutch brake couplings makes them suitable for a wide range of applications across various industries, including:

- Manufacturing: In automated assembly lines, these couplings facilitate precise indexing and positioning of workpieces, ensuring smooth and efficient production processes.

- Packaging: Packaging machinery relies on these couplings for accurate material feeding, cutting, and sealing operations.

- Printing: High-speed printing presses utilize these couplings for precise web tension control, ensuring high-quality printing output.

- Automotive: In vehicles, particularly those with automatic transmissions, these couplings play a role in smooth gear shifting and power transmission.

This list represents just a fraction of the many industries and applications where Warner clutch brake couplings play a vital role. Their ability to combine controlled power transmission with braking functionality makes them indispensable components in numerous machinery systems.

Common Issues and Troubleshooting

While Warner clutch brake couplings are known for their reliability and durability, like any mechanical device, they may encounter issues over time. Some common problems include:

- Clutch Slippage: This occurs when the clutch fails to transmit the full torque, resulting in reduced power to the driven load. Possible causes include worn friction surfaces, insufficient actuation pressure, or improper adjustments.

- Brake Drag: Brake drag happens when the brake doesn’t fully release, creating friction and reducing efficiency. This issue can stem from worn brake linings, damaged actuators, or misaligned components.

- Overheating: Excessive heat generation can indicate a problem with the clutch or brake system, often caused by overloading, improper lubrication, or malfunctioning cooling systems.

Troubleshooting a Warner Clutch Brake Coupling

Troubleshooting a Warner Clutch Brake Coupling

Remote Diagnostics and Software Solutions

In today’s technologically advanced world, remote diagnostics and software solutions play a crucial role in troubleshooting and maintaining Warner clutch brake couplings. By leveraging these advanced tools, technicians can:

- Access Real-Time Data: Remote monitoring systems provide real-time data on the coupling’s performance, including speed, torque, temperature, and actuation pressures. This data allows for proactive identification of potential issues before they escalate into major problems.

- Perform Remote Diagnostics: Specialized software enables technicians to remotely diagnose faults, analyze error codes, and pinpoint the root cause of malfunctions. This remote access minimizes downtime and allows for quicker problem resolution.

- Implement Software Updates: Manufacturers often release software updates that optimize the coupling’s performance, improve efficiency, and enhance safety features. Remote software installation ensures that the coupling operates with the latest enhancements and functionalities.

warner electric clutches and brakes 5353-631-001 new

These advanced diagnostic and software capabilities streamline maintenance procedures, reduce downtime, and extend the operational life of Warner clutch brake couplings.

Conclusion

The Warner clutch brake coupling is a testament to engineering ingenuity, effectively combining power transmission and braking functionalities into a single, compact unit. Its versatility and reliability have made it an essential component in various industries, contributing to improved efficiency, precision, and safety in countless applications.

Understanding the workings, applications, and potential issues associated with Warner clutch brake couplings is crucial for ensuring optimal performance and longevity. By embracing remote diagnostics, software solutions, and proactive maintenance practices, industries can maximize the benefits of this remarkable device and maintain seamless operations.

For more information on specific Warner clutch and brake products, you can explore our selection of warner clutches and brakes.