Brake service and clutch service are crucial for vehicle safety and performance. When it comes to Warner electric brakes and clutches, understanding their intricacies can be particularly important. This guide will provide valuable insights into these systems, addressing common issues, diagnostic techniques, remote programming options, and best practices for maintenance.

For those seeking brake service specifically, you might find our page on Brakes Plus Gilbert Warner helpful. brakes plus gilbert warner This guide explores the importance of proper brake and clutch maintenance and how neglecting these systems can lead to costly repairs and safety hazards.

Understanding Warner Electric Brake & Clutch Systems

Warner electric brakes and clutches are commonly found in various vehicles and industrial machinery. They offer precise control and reliable performance, but like any mechanical system, they require regular maintenance and occasional repair. Identifying potential issues early on can prevent major breakdowns and ensure optimal functionality. These systems utilize electromagnetic forces to engage and disengage, offering significant advantages in terms of response time and controllability compared to traditional hydraulic systems.

Common Issues with Warner Brakes and Clutches

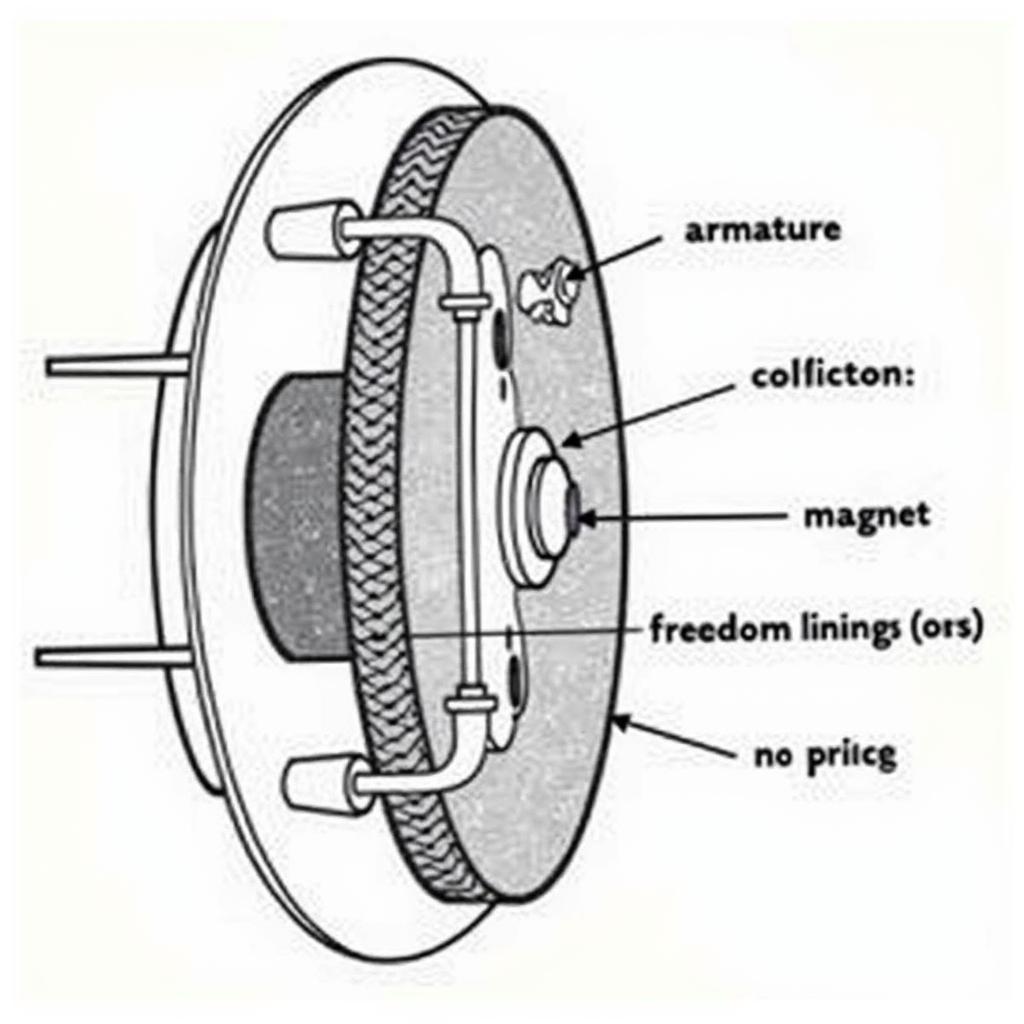

Several factors can contribute to problems with Warner electric brakes and clutches. Wear and tear on components like friction linings, springs, and armatures are common. Electrical issues can also arise, affecting the solenoids, wiring, and control modules. Additionally, environmental factors such as moisture, dirt, and extreme temperatures can negatively impact performance.

You can find more information on specific Warner Electric brake products warner electric brake & and their functionalities.

Warner Brake and Clutch Components

Warner Brake and Clutch Components

Diagnostic Techniques and Remote Solutions

Diagnosing issues with Warner electric brakes and clutches requires a systematic approach. Visual inspections can reveal obvious signs of wear or damage. Specialized diagnostic tools can be used to assess the electrical system and identify any faults in the wiring, solenoids, or control modules. Remote programming and software updates are also becoming increasingly prevalent, allowing technicians to address certain issues without physical access to the vehicle, significantly streamlining the repair process.

For heavy-duty applications, check out the warner electric brake and clutches pb-1225 heavy duty page for specific details.

Leveraging Remote Programming for Brake and Clutch Service

Remote programming offers numerous benefits for both technicians and vehicle owners. It can expedite repairs, reduce downtime, and even enable preventative maintenance by allowing for remote monitoring and analysis of system performance. This technology is revolutionizing how we approach brake service and clutch service, offering greater efficiency and convenience.

Maintaining Warner Brake and Clutch Systems

Regular maintenance is essential for prolonging the lifespan and ensuring the reliability of Warner electric brakes and clutches. This includes routine inspections, adjustments, and replacement of worn components. Keeping the system clean and free of debris is also crucial.

More information on Warner brakes can be found on our warner brakes page.

Preventing Common Problems

Following recommended maintenance schedules and addressing minor issues promptly can prevent more significant problems from developing. Proper lubrication, periodic inspections of wiring and connections, and adhering to load capacity guidelines are crucial for maintaining optimal performance and preventing premature wear.

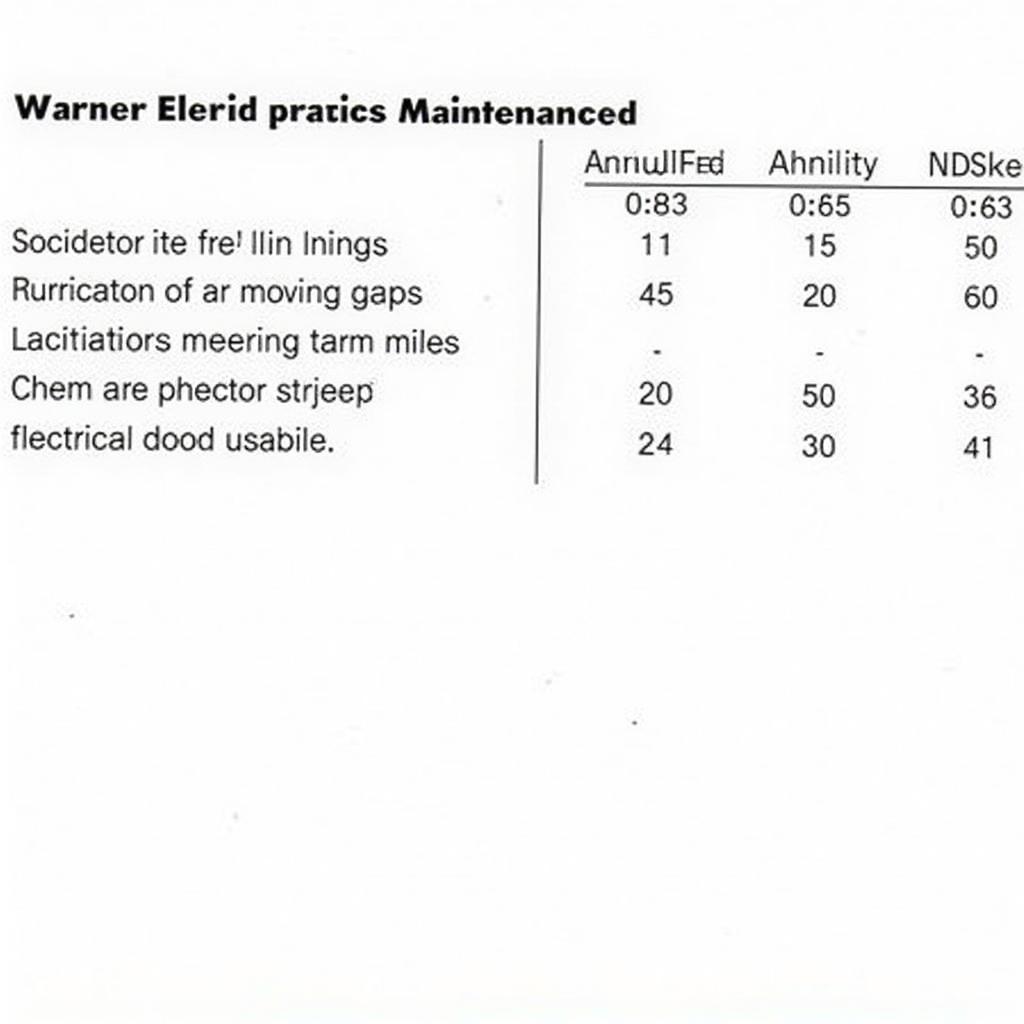

Warner Brake Maintenance Checklist

Warner Brake Maintenance Checklist

Conclusion

Proper brake service and clutch service, especially for Warner systems, are paramount for vehicle safety and performance. Understanding these systems, their potential issues, and leveraging modern diagnostic and programming techniques can ensure optimal functionality and longevity. Regular maintenance and preventative measures are key to avoiding costly repairs and maximizing the lifespan of these critical components. Remember to prioritize regular inspections and address any concerns promptly for optimal brake and clutch performance and, most importantly, your safety on the road. For more insights, explore our resources on clutch brake warner electric.