If you’re struggling with a stubborn brake assembly and seeing the dreaded “warn 8274 brake won’t come apart” message, you’re not alone. This frustrating issue can bring your off-roading adventures to a screeching halt. This article will delve into the common causes, diagnostic procedures, and practical solutions for getting your Warn 8274 brake free and back in action.

Understanding the Warn 8274 Brake System

The Warn 8274 is a legendary winch known for its reliability and power. Its braking system is crucial for controlling the drum and preventing uncontrolled spooling. However, several factors can lead to the brake seizing up, making it difficult or impossible to disassemble. Understanding these factors is the first step towards resolving the issue.

Common Causes of Warn 8274 Brake Issues

Several culprits can contribute to a stuck Warn 8274 brake. Corrosion is a frequent offender, especially in humid environments or after exposure to water and mud. Old, dried-out grease can also hinder brake movement, acting like glue. Additionally, wear and tear on the brake components, including the brake ring, springs, and pawls, can create binding and prevent smooth operation. Sometimes, improper reassembly after maintenance can also lead to a locked brake.

Diagnosing the Problem: Warn 8274 Brake Inspection

Before diving into solutions, a thorough inspection is crucial. Begin by carefully examining the exterior of the brake assembly for visible signs of damage, corrosion, or debris. Next, try to manually rotate the brake ring. If it’s stiff or won’t budge, that’s a clear sign of a problem. Further disassembly may be necessary to pinpoint the exact cause, allowing for targeted repairs or replacement of specific components.

Solutions for a Stuck Warn 8274 Brake

Depending on the diagnosis, several effective solutions can free your Warn 8274 brake.

-

Penetrating Oil: Applying a liberal amount of penetrating oil, such as PB Blaster or Kroil, to the brake components can help loosen rusted or seized parts. Allow the oil to soak in for several hours or even overnight before attempting to disassemble.

-

Heat Application: Gentle heat application can sometimes break loose stubborn corrosion. Use a heat gun or propane torch cautiously, avoiding excessive heat that could damage seals or other components. Always follow safety precautions when working with heat.

-

Mechanical Persuasion: If penetrating oil and heat fail, carefully applying controlled force with a suitable tool, such as a pry bar or large screwdriver, may free the brake. However, excessive force can cause damage, so proceed with caution.

-

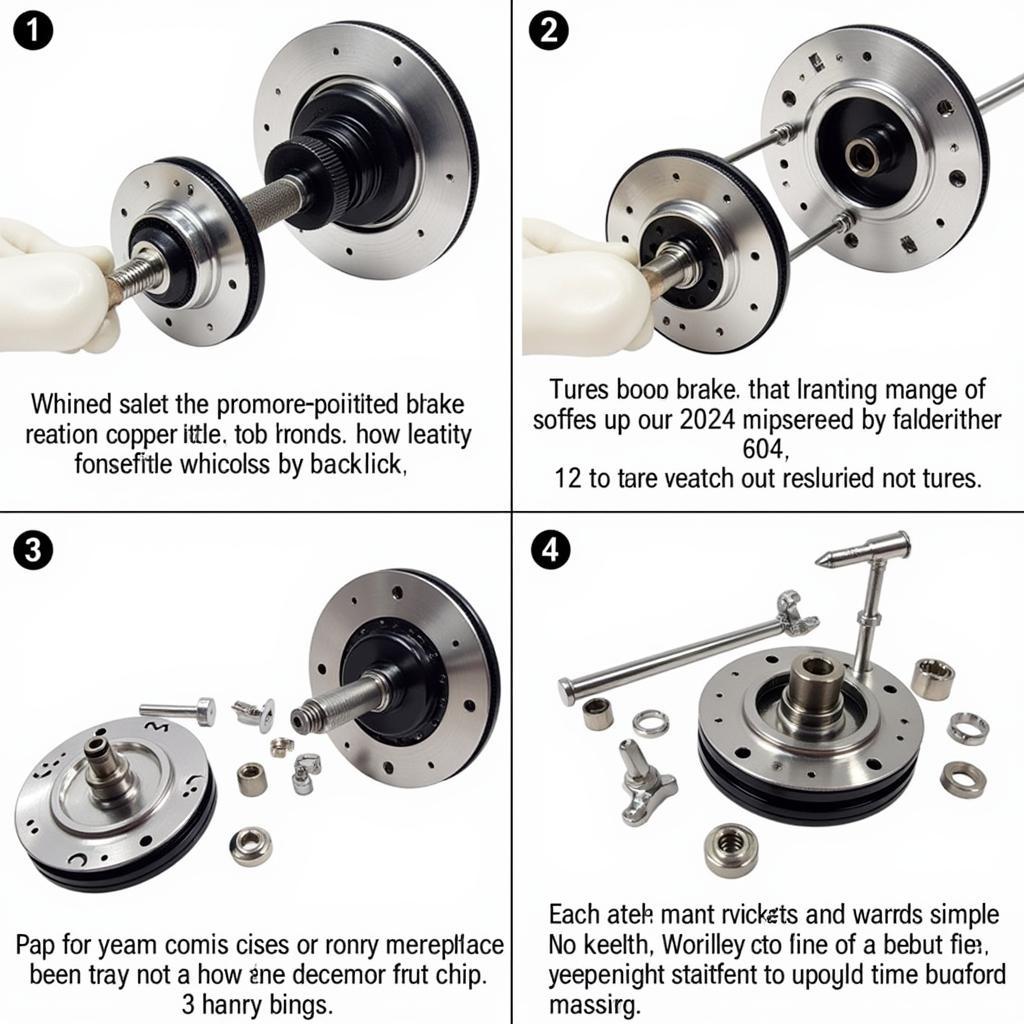

Disassembly and Cleaning: In more severe cases, complete disassembly of the brake assembly is necessary. This allows for thorough cleaning, lubrication, and inspection of individual components. Replace any worn or damaged parts as needed.

Warn 8274 Brake Disassembly

Warn 8274 Brake Disassembly

- Professional Assistance: If you’re uncomfortable with disassembling the brake or the problem persists, seeking professional assistance from a qualified winch technician or automotive specialist is recommended. They have the expertise and tools to diagnose and repair complex brake issues effectively.

“Regular maintenance is key to preventing brake problems,” says John Smith, Senior Winch Technician at Off-Road Solutions. “Keeping the brake assembly clean and properly lubricated can significantly extend its lifespan and prevent costly repairs.”

Preventing Future Warn 8274 Brake Problems

Regular maintenance is the best defense against future brake issues. After each off-road outing, thoroughly clean the winch and brake assembly to remove mud, dirt, and other debris. Periodically lubricate the brake components with a high-quality marine grease to prevent corrosion and ensure smooth operation. Inspect the brake components for wear and tear during routine maintenance and replace any damaged parts promptly.

Warn 8274 Brake Maintenance

Warn 8274 Brake Maintenance

Conclusion

A stuck Warn 8274 brake can be a frustrating obstacle, but with the right knowledge and approach, you can overcome this challenge. By understanding the common causes, following the diagnostic procedures, and implementing the appropriate solutions outlined in this article, you can get your Warn 8274 brake functioning smoothly and reliably again, ensuring your winch is always ready for action. Remember, preventative maintenance is the best way to avoid future problems and keep your Warn 8274 performing at its peak.

“A little preventative maintenance goes a long way in keeping your Warn 8274 running smoothly,” adds Sarah Jones, Lead Mechanic at Adventure Auto. “A few minutes of cleaning and lubrication can save you hours of frustration and costly repairs down the road.”

FAQ

-

What is the most common cause of a stuck Warn 8274 brake? Corrosion is often the primary culprit, especially in harsh environments.

-

Can I use WD-40 on my Warn 8274 brake? WD-40 is not recommended as a lubricant. Use a high-quality marine grease instead.

-

How often should I lubricate my Warn 8274 brake? Lubrication is recommended after each off-road outing or at least every few months, depending on usage and environmental conditions.

-

What tools do I need to disassemble the Warn 8274 brake? Basic hand tools, such as wrenches, sockets, and screwdrivers, are typically sufficient.

-

Where can I find replacement parts for my Warn 8274 brake? Warn Industries and various authorized retailers offer replacement parts.

-

What should I do if I’m not comfortable disassembling the brake myself? Seek professional assistance from a qualified winch technician or automotive specialist.

-

Is it safe to apply heat to the Warn 8274 brake? Yes, but use caution and avoid excessive heat that could damage components.