Attaching spring Borg Warner brakes can seem daunting, but with the right guidance, it’s a manageable task. This guide will provide a step-by-step approach to help you confidently tackle this process, whether you’re a seasoned mechanic or a DIY enthusiast.

Understanding Borg Warner Brake Springs

Before diving into the attachment process, it’s essential to understand the role of these springs. Borg Warner brakes are known for their robust design and dependable performance. The springs are crucial components, ensuring proper retraction of the brake shoes after application, preventing dragging and overheating. Different Borg Warner brake systems may use variations of spring designs, so it’s crucial to identify your specific system before proceeding. This will ensure you use the correct springs and follow the appropriate procedure.

Gathering Your Tools and Materials

Having the right tools at hand will significantly simplify the process. You’ll typically need:

- Spring pliers (specifically designed for brake springs)

- Brake spoon

- Small flathead screwdriver

- Safety glasses

- Work gloves

- Penetrating oil (if dealing with rusty components)

- Service manual for your specific vehicle

Step-by-Step Guide to Attaching the Springs

- Prepare the Brake Assembly: Ensure the brake drum is removed and the brake shoes are accessible. Clean the brake assembly thoroughly to remove any dirt, grease, or debris that could interfere with the spring attachment. Apply penetrating oil to rusty parts to ease the process.

- Identify the Spring Locations: Consult your service manual to identify the correct location for each spring. Borg Warner brake systems often utilize multiple springs with varying tensions and functions. Misplacing a spring can lead to improper brake function.

- Attach the Hold-Down Springs: These springs typically secure the brake shoes to the backing plate. Use spring pliers to carefully hook one end of the spring onto the designated location on the shoe and the other end to the backing plate.

- Install the Return Springs: Return springs are responsible for retracting the brake shoes after braking. These are often more challenging to install due to higher tension. Use the spring pliers to carefully stretch and position the spring onto its designated hooks on the shoe and anchor point.

- Connect the Parking Brake Cable Spring: If your vehicle has a drum-in-hat parking brake system, ensure the parking brake cable spring is correctly attached to the lever and equalizer. This spring is vital for proper parking brake operation.

- Double-Check Your Work: Before reassembling the brake drum, meticulously inspect all springs to ensure they are correctly seated and securely attached. Any loose or misaligned springs can compromise brake performance and safety.

Attaching Borg Warner Brake Springs

Attaching Borg Warner Brake Springs

Common Challenges and Troubleshooting

Sometimes, attaching these springs can be tricky. Here are some common challenges and how to overcome them:

- Difficulty Hooking the Spring: Use a brake spoon or small flathead screwdriver to assist in guiding the spring onto its hook.

- Spring Slipping Off: Ensure the spring pliers have a firm grip on the spring. Using a second pair of pliers can help stabilize the spring while attaching it.

- Rusty Components: Applying penetrating oil and allowing it to soak for a few minutes can significantly ease the process of working with rusted components.

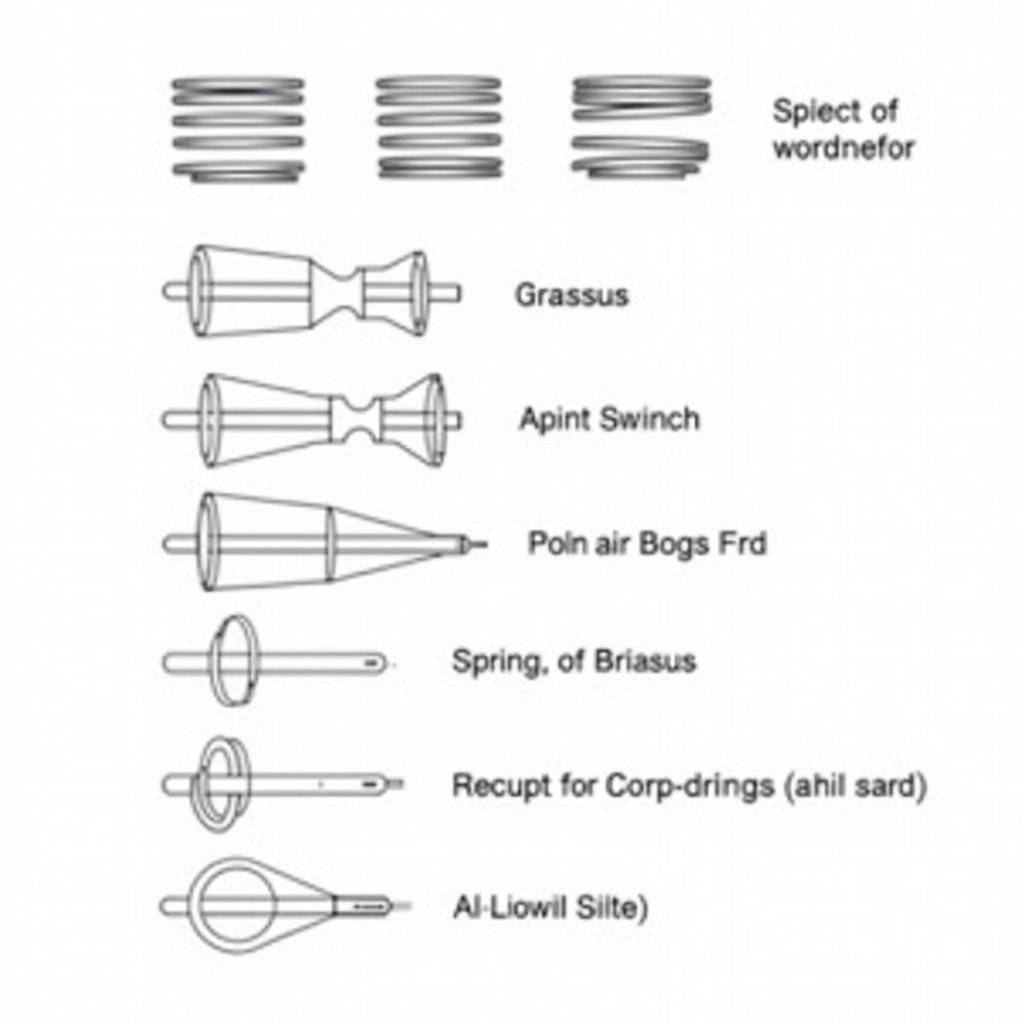

Different Borg Warner Brake Spring Types

Different Borg Warner Brake Spring Types

Importance of Proper Spring Installation

Proper spring installation is paramount for safe and effective braking. Incorrectly attached springs can lead to various issues, including:

- Brake Drag: This can cause overheating, premature wear of brake components, and reduced fuel efficiency.

- Uneven Braking: This can pull the vehicle to one side during braking, compromising stability and control.

- Parking Brake Failure: A misaligned or detached parking brake cable spring can result in a malfunctioning parking brake.

Expert Insights

“Attaching brake springs correctly is essential for optimal braking performance,” says John Smith, a seasoned automotive technician with over 20 years of experience. “Taking the time to understand your specific brake system and using the right tools can prevent potential problems down the road.”

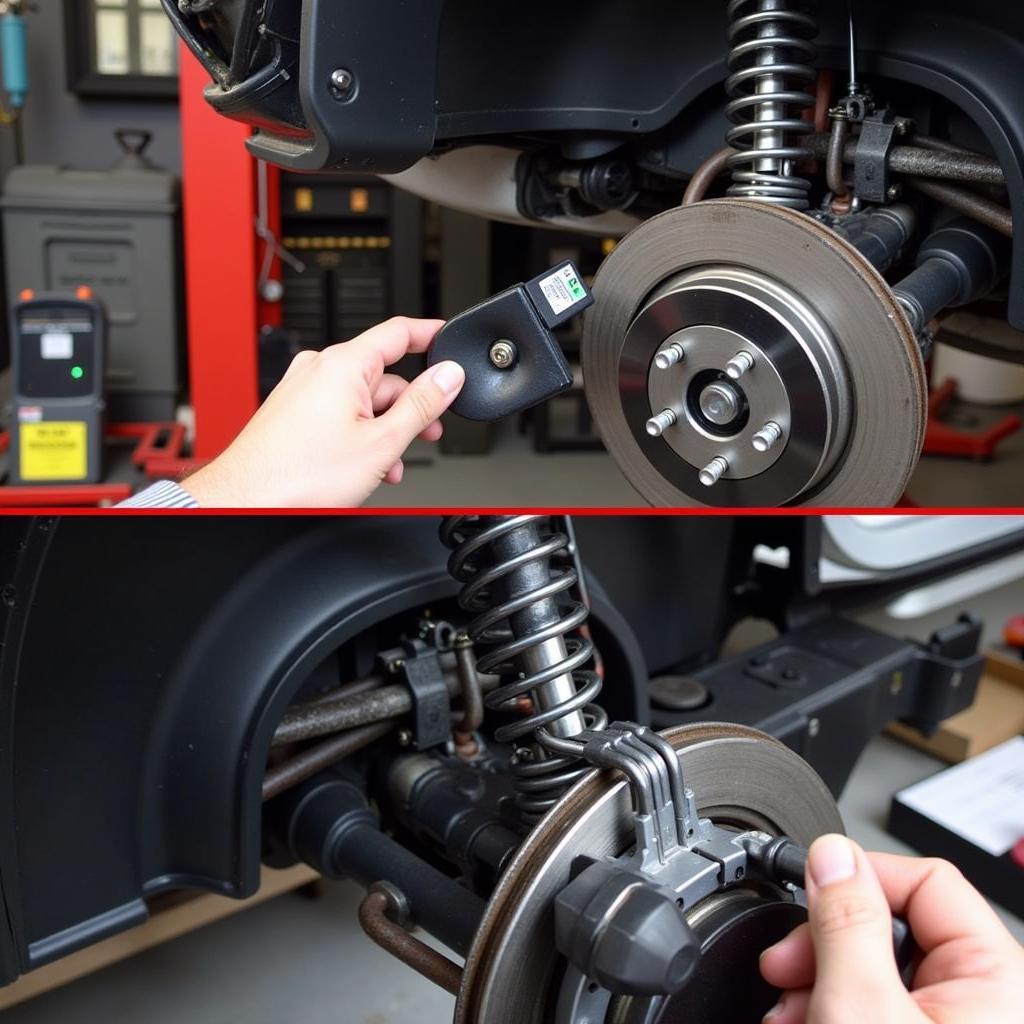

Checking Borg Warner Brake Springs After Installation

Checking Borg Warner Brake Springs After Installation

Conclusion

Attaching spring Borg Warner brakes requires attention to detail and the right tools. Following this guide and referencing your vehicle’s service manual will ensure a successful installation. Remember, properly installed brake springs are vital for safe and efficient braking, so take your time and double-check your work.

FAQ

- What type of pliers are best for attaching brake springs? Specialized brake spring pliers are recommended for their designed grip and leverage.

- Do I need a service manual for this task? Yes, consulting your vehicle’s service manual is crucial for identifying the correct spring locations and procedures.

- What happens if a brake spring is installed incorrectly? Incorrectly installed springs can lead to brake drag, uneven braking, or parking brake failure.

- Can I reuse old brake springs? While it’s possible, it’s generally recommended to replace brake springs with new ones during a brake job.

- How often should brake springs be inspected? Brake springs should be inspected during every brake service or anytime brake issues are suspected.

- What should I do if I’m struggling to attach a spring? Consider using a brake spoon or seeking assistance from a qualified mechanic.

- Why are Borg Warner brakes considered reliable? Borg Warner brakes are known for their robust design and dependable performance, making them a popular choice in many vehicles.