Borg Warner air brake valves are critical components in heavy-duty vehicles, ensuring safe and reliable braking performance. A malfunctioning valve can lead to serious safety hazards, making prompt diagnosis and repair essential. This guide delves into common issues, troubleshooting techniques, and remote programming solutions for Borg Warner air brake valves, offering valuable insights for both professionals and DIY enthusiasts.

Understanding Borg Warner Air Brake Valves and Their Importance

These valves control the flow of compressed air to the brake chambers, enabling the vehicle to stop effectively. Their precise operation is crucial for maintaining control and preventing accidents. Different types of Borg Warner air brake valves exist, each designed for specific applications, such as relay valves, quick release valves, and modulator valves. Understanding the specific type in your vehicle is vital for accurate troubleshooting. Regular maintenance and timely repairs are key to ensuring their optimal performance and longevity.

Common Problems with Borg Warner Air Brake Valves

Several issues can arise with these valves, ranging from air leaks and slow response times to complete system failure. Air leaks are often caused by worn seals or damaged components within the valve. Slow response times can be attributed to clogged air lines or internal valve malfunctions. Complete system failure can result from severe damage or electrical issues. Recognizing these symptoms early is crucial for preventing further damage and ensuring safety.

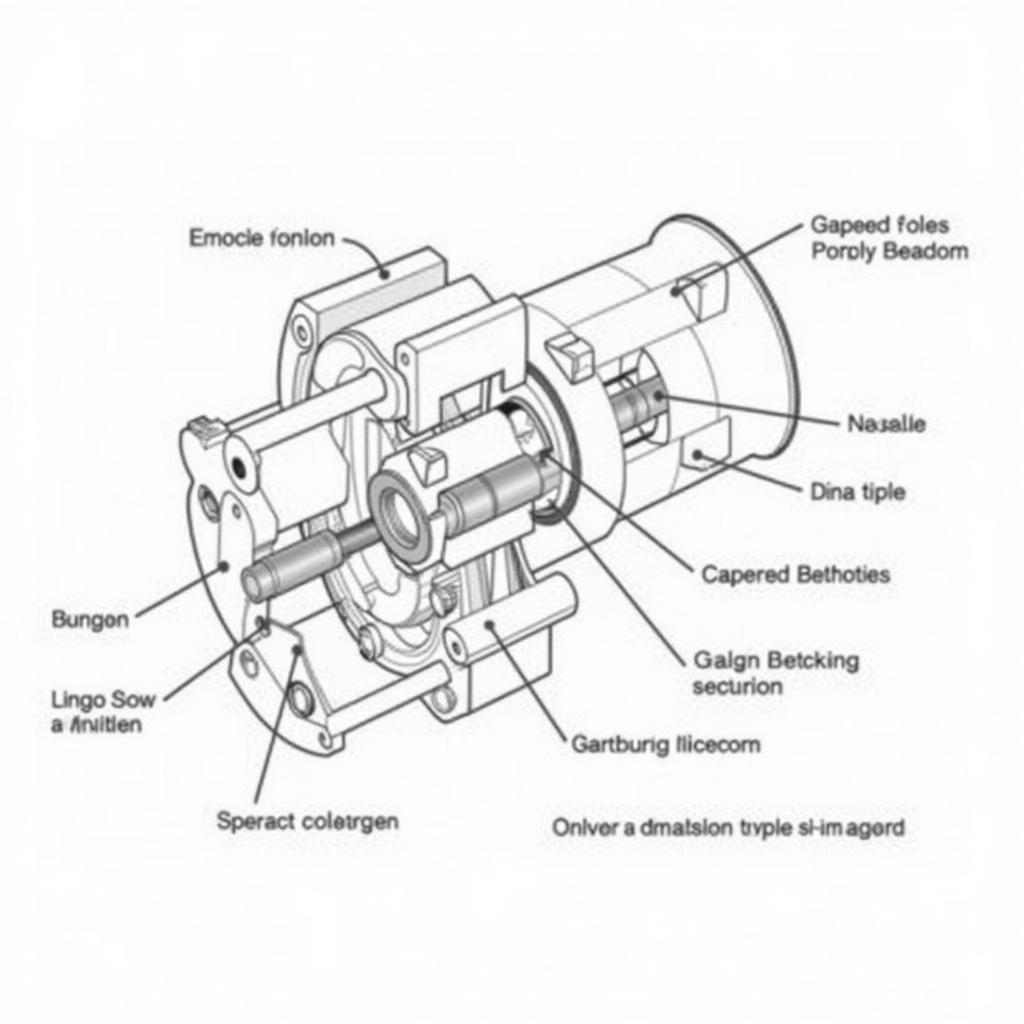

Borg Warner Air Brake Valve Diagram

Borg Warner Air Brake Valve Diagram

Diagnosing Borg Warner Air Brake Valve Problems

Diagnosing these issues requires a systematic approach. Start by visually inspecting the valve for any obvious signs of damage, such as cracks, leaks, or loose connections. Then, check the air pressure in the system using a gauge, ensuring it meets the manufacturer’s specifications. If the pressure is low, locate the source of the leak. Use soapy water to identify leaks in air lines and fittings. For internal valve issues, specialized diagnostic tools may be necessary.

Remote Programming and Software Solutions

Modern Borg Warner air brake valves often incorporate electronic control units (ECUs) that can be programmed remotely. This technology allows for efficient diagnostics and adjustments without physical access to the valve. Remote programming can be used to calibrate the valve, update its software, and troubleshoot specific error codes. This can significantly reduce downtime and repair costs.

Remote Programming of a Borg Warner Air Brake Valve

Remote Programming of a Borg Warner Air Brake Valve

DIY vs. Professional Repair: When to Seek Expert Help

While some minor issues can be addressed by knowledgeable DIYers, complex problems often require the expertise of a qualified technician. If you’re unsure about the cause of the problem or lack the necessary tools and experience, it’s always best to seek professional assistance. Attempting complex repairs without proper training can worsen the issue and potentially compromise safety.

Preventive Maintenance for Borg Warner Air Brake Valves

Regular maintenance is essential for preventing problems and extending the lifespan of your air brake valves. This includes routine inspections, cleaning, lubrication, and replacement of worn components. Adhering to the manufacturer’s recommended maintenance schedule can significantly reduce the risk of unexpected failures.

Maintaining a Borg Warner Air Brake Valve

Maintaining a Borg Warner Air Brake Valve

Conclusion

Properly functioning Borg Warner air brake valves are crucial for safe and reliable vehicle operation. Understanding the common problems, diagnostic procedures, and available repair options empowers you to address issues promptly and effectively. By prioritizing regular maintenance and seeking professional help when needed, you can ensure the long-term performance and safety of your vehicle’s braking system. Remember, a well-maintained air brake system is a vital investment in safety.