The 1.9 TDI engine, renowned for its reliability and fuel efficiency, relies heavily on a properly functioning injection pump. This pump is responsible for delivering precise amounts of fuel to the cylinders at extremely high pressure. Any deviation from its optimal performance can lead to a drop in power, reduced fuel economy, and even engine damage.

This article will guide you through the process of checking your 1.9 TDI injection pump’s performance using VCDS (Vag-Com Diagnostic System), a powerful diagnostic tool that allows you to access and analyze your vehicle’s engine control unit (ECU).

What is VCDS and Why Use it for Injection Pump Diagnostics?

VCDS is a Windows-based software package developed by Ross-Tech, specifically designed to communicate with the ECUs of Volkswagen Group vehicles (Volkswagen, Audi, Seat, Skoda). Unlike generic OBD-II scanners, VCDS offers a comprehensive suite of features, including:

- Reading and clearing fault codes: Identify specific issues within your engine management system.

- Live data monitoring: Observe real-time sensor readings, including injection timing, fuel pressure, and more.

- Actuator tests: Command various components to activate, helping isolate faulty parts.

- Adaptation and coding: Fine-tune specific parameters within the ECU for optimal performance.

For diagnosing a 1.9 TDI injection pump, VCDS provides the necessary depth and functionality to pinpoint problems accurately.

Checking Injection Pump Performance with VCDS: A Step-by-Step Guide

Before You Begin:

- Ensure you have a genuine VCDS interface and the software is installed correctly on your Windows laptop.

- Park your vehicle on a level surface, engage the parking brake, and switch off the engine.

- Locate your vehicle’s OBD-II port, typically found under the dashboard on the driver’s side.

Step 1: Connecting and Identifying

- Connect the VCDS interface to your laptop and the vehicle’s OBD-II port.

- Turn on the ignition but do not start the engine.

- Launch the VCDS software and establish communication with your vehicle’s ECU.

- Select the appropriate control module for your engine. This is usually labeled “Engine” or has a numerical code like “01-Engine.”

Step 2: Monitoring Live Data

- Once inside the engine module, navigate to the “Measuring Blocks” or “Live Data” section.

- Here, you’ll find a list of measurable parameters. Look for values related to the injection pump, such as:

- Injection Quantity Deviation: This value indicates the difference in fuel delivery between the individual cylinders. Ideally, it should be close to zero.

- Injection Timing: This displays the timing of fuel injection relative to piston position. It should fall within the manufacturer’s specified range.

- Fuel Pressure: Check the actual fuel pressure against the specified values. Low pressure can indicate pump wear or a fuel supply issue.

- Start of Injection (SOI): This crucial parameter indicates the timing of fuel injection in relation to crankshaft position. It should align with the manufacturer’s specifications.

Step 3: Interpreting the Data

- Carefully observe the live data readings as you increase engine speed.

- Deviations from the expected values, particularly under load or acceleration, can indicate a problem with the injection pump.

- Pay close attention to fluctuations, spikes, or drops in values, which could signify a failing pump or related sensors.

Step 4: Advanced Diagnostics

- Log Data: For in-depth analysis, consider logging the live data while driving the vehicle under different load conditions.

- Compare to Specifications: Cross-reference your findings with the manufacturer’s specifications for your specific 1.9 TDI engine code.

- Consult a Professional: If the data analysis reveals significant deviations or you suspect a faulty injection pump, it’s best to consult a qualified diesel mechanic or a Volkswagen specialist for further diagnosis and repair.

FAQs

Q1: Can I adjust injection pump settings with VCDS?

Yes, VCDS allows for certain adaptations and adjustments to the injection pump timing, but it is crucial to proceed with caution. Improper adjustments can negatively impact engine performance and even cause damage. Consult a specialist or refer to detailed technical manuals before making any alterations.

Q2: What are common symptoms of a failing 1.9 TDI injection pump?

Symptoms can vary but may include:

- Difficult starting, especially when cold

- Rough idling and engine misfires

- Reduced power and acceleration

- Increased smoke, particularly black smoke under acceleration

- Poor fuel economy

Q3: Can I clean or repair a 1.9 TDI injection pump myself?

While some components, like fuel filters, are user-serviceable, directly working on the injection pump requires specialized tools, knowledge, and experience. It’s generally recommended to leave internal pump repairs to qualified professionals to avoid causing further damage.

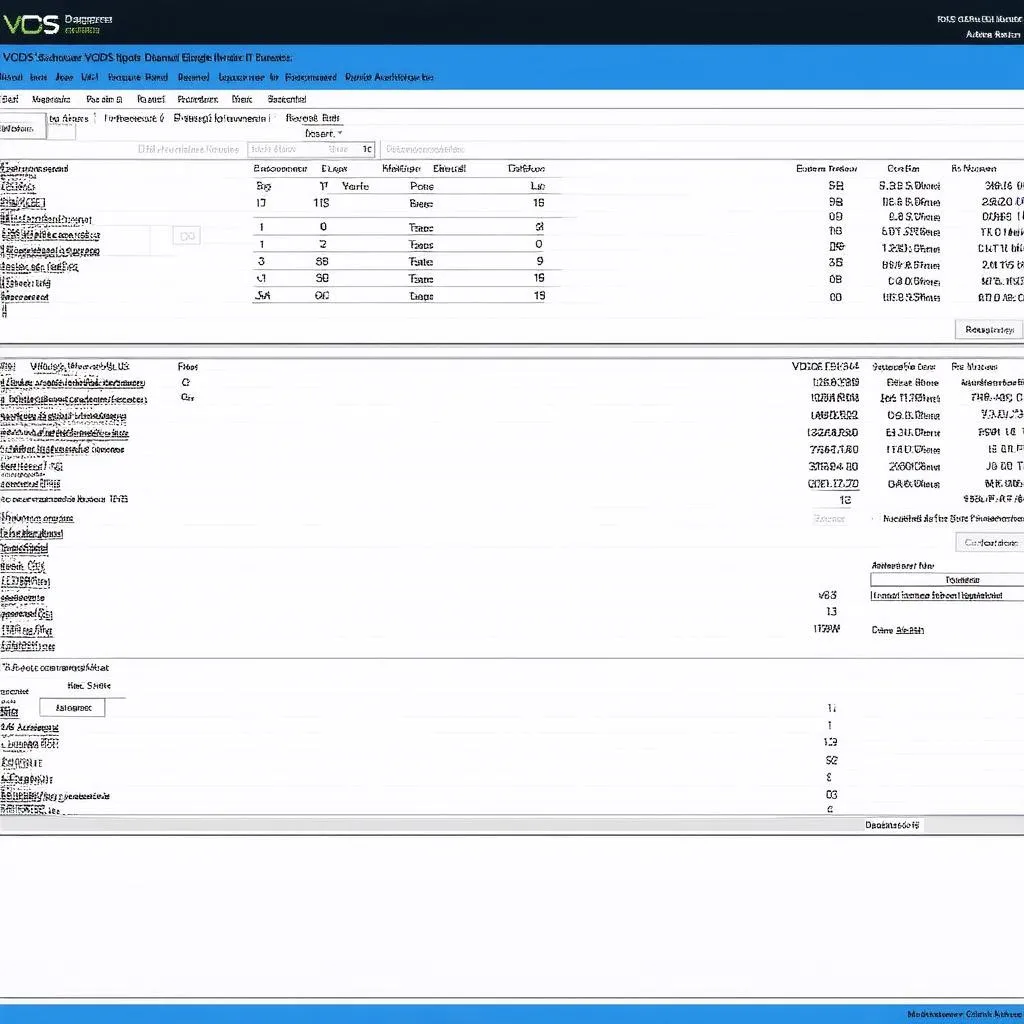

VCDS Software and Interface

VCDS Software and Interface

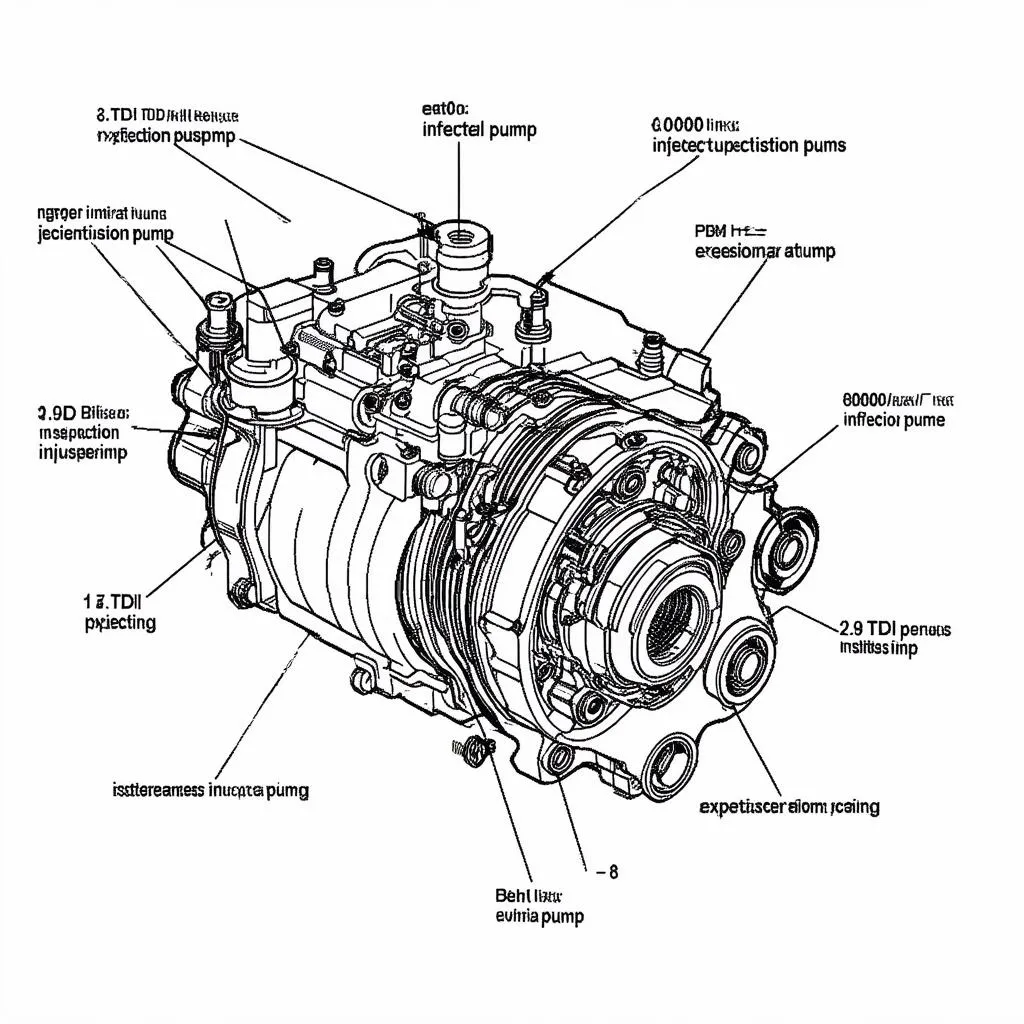

Injection Pump Diagram

Injection Pump Diagram

Conclusion

Checking the performance of your 1.9 TDI injection pump using VCDS provides valuable insights into the health of this vital engine component. By understanding the key parameters and interpreting the data correctly, you can identify potential problems early on, preventing costly repairs and ensuring the longevity of your engine. Remember, while VCDS is a powerful tool, it’s always advisable to seek professional help if you encounter complex issues or are unsure about interpreting the diagnostic results. For further assistance or inquiries, feel free to reach out to the experts at CARDIAGTECH.