Removing the brake on a Warn winch can be a necessary step for maintenance, repair, or modification. Whether you’re experiencing issues with your winch brake or planning an upgrade, understanding the process is crucial. This guide provides a detailed walkthrough on how to remove a Warn winch brake, covering various models and common troubleshooting tips.  Warn Winch Brake Removal Process

Warn Winch Brake Removal Process

Understanding the Warn Winch Brake System

Before diving into the removal process, it’s essential to understand the Warn winch brake system. The brake is a critical safety component, preventing uncontrolled spooling and ensuring your load remains secure. Different Warn winch models employ slightly different brake mechanisms. For instance, some feature a cone-style brake, while others use a disc or drum brake system. Knowing your specific winch model is essential for identifying the correct removal procedure.

What are the common types of Warn winch brakes? Well, you’ll typically find drum brakes and disc brakes, each with their own advantages. Drum brakes are known for their robust design and holding power, while disc brakes offer superior heat dissipation, crucial for heavy-duty winching. warn 8274 brake removal is a common search term for those with older models.

Preparing for Brake Removal

Safety first! Disconnect the winch’s power supply before starting any work. This prevents accidental activation and ensures your safety during the removal process. Gather the necessary tools, which may include wrenches, sockets, pliers, and a retaining ring pliers, depending on your winch model. Refer to your winch’s user manual for the specific tools required. Proper preparation will make the process smoother and more efficient.

Step-by-Step Brake Removal

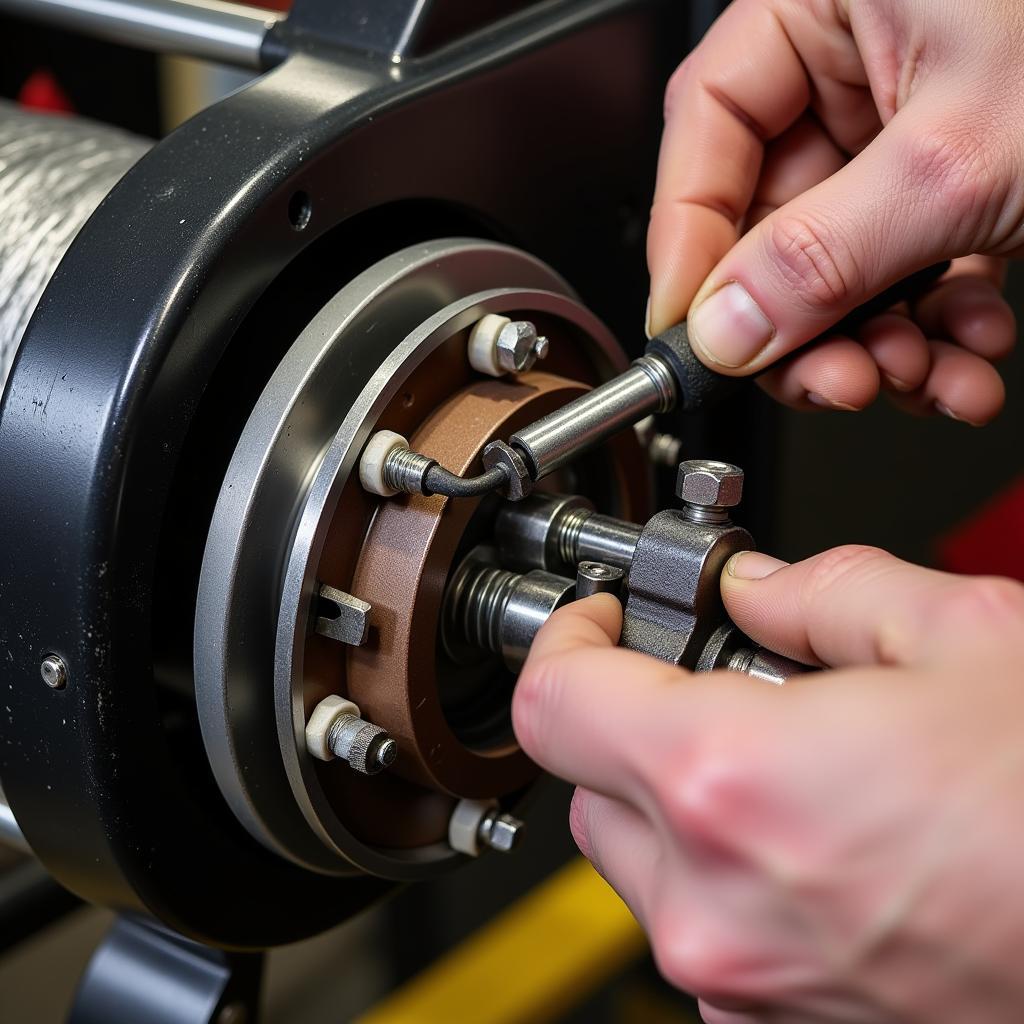

- Locate the brake assembly: The brake assembly is typically located behind the drum or near the motor end of the winch.

- Remove the retaining ring/circlip: This ring secures the brake drum or disc. Use retaining ring pliers to carefully remove it.

- Remove the drum/disc: Once the retaining ring is removed, carefully slide the drum or disc off the shaft.

- Inspect the brake components: Examine the brake pads, springs, and other components for wear or damage. If you find any worn or damaged parts, replace them with genuine Warn parts. Using the wrong parts can compromise the brake’s performance and safety. warn 8274 brake wont come apart is a common issue; ensure you’re using the correct tools and technique.

- Reassemble (if not replacing): If you’re not replacing the brake, carefully reassemble the components in the reverse order, ensuring everything is correctly aligned and secured.

“A well-maintained winch brake is vital for safe and reliable operation,” says John Miller, a certified automotive technician with 20 years of experience. “Regular inspection and timely replacement of worn parts are crucial for preventing potential problems.” warn winch brake doesnt hold winding opposite direction suggests potential issues with the brake mechanism itself and warrants a thorough inspection.

Common Problems and Troubleshooting

Sometimes, the brake can be stubborn. warn winch brake pads are often a source of issues if worn or incorrectly installed. If the brake drum or disc won’t come off, it might be seized due to rust or corrosion. Apply penetrating oil and allow it to soak before trying again. If you’re still having trouble, consult a qualified technician.

“Using the right tools and following the correct procedure are key to a successful brake removal,” adds Sarah Chen, a mechanical engineer specializing in winch systems. “Don’t force anything; if you encounter resistance, double-check the steps and seek expert advice if needed.” Considering a warn belleview winch brake upgrade? Ensure compatibility and follow the manufacturer’s instructions carefully.

Conclusion

Removing a Warn winch brake requires careful attention to detail and adherence to the correct procedure. By following the steps outlined in this guide and understanding the common troubleshooting tips, you can successfully remove your winch brake for maintenance, repair, or upgrades. Remember to always prioritize safety and consult your winch’s user manual for specific instructions related to your model. A properly functioning brake is paramount for safe and efficient winching operations.

FAQ

- Why would I need to remove my Warn winch brake? Common reasons include brake maintenance, repair, or upgrading to a higher-performance brake system.

- What tools do I need to remove a Warn winch brake? The specific tools vary depending on the winch model, but commonly include wrenches, sockets, pliers, and a retaining ring pliers.

- What should I do if the brake drum is seized? Apply penetrating oil and allow it to soak before attempting removal again.

- Where can I find the correct brake replacement parts for my Warn winch? Always use genuine Warn parts, which can be purchased from authorized dealers or online retailers.

- What safety precautions should I take when removing the brake? Always disconnect the winch’s power supply before starting any work to prevent accidental activation.

- Do I need any special skills to remove the brake? While basic mechanical skills are helpful, always refer to the user manual and seek professional assistance if needed.

- How often should I inspect my Warn winch brake? Regular inspection, at least annually or more frequently with heavy use, is recommended.