Understanding the intricacies of your car’s turbo system can be daunting, especially when issues arise. The N75 valve, a critical component controlling boost pressure, often plays a central role in these problems. Performing a “test n75 vcds” is a key diagnostic step for identifying the source of turbo-related malfunctions. This guide will equip you with the knowledge to understand the N75 valve’s function, common issues, and how to effectively test it using VCDS.

Understanding the N75 Valve’s Role

The N75 valve, also known as the boost control solenoid, is the gatekeeper of your turbocharger’s boost pressure. It regulates the pressure by controlling the flow of exhaust gases that spin the turbine. The engine’s ECU (Electronic Control Unit) commands the N75 valve, precisely adjusting boost based on driving conditions. A malfunctioning N75 can lead to overboost, underboost, or erratic boost fluctuations, significantly impacting engine performance.

Common N75 Valve Issues

Several issues can plague the N75 valve, leading to performance problems. These include:

- Sticking Valve: A sticky N75 valve can become stuck open or closed, disrupting boost regulation. This often results in limp mode or reduced power.

- Electrical Malfunction: A faulty electrical connection or internal short circuit can prevent the N75 from functioning correctly.

- Vacuum Leaks: Leaks in the vacuum lines connected to the N75 can compromise its ability to control boost pressure.

- Failed Diaphragm: Internal damage to the valve’s diaphragm can cause erratic boost control.

A vcds n75 test helps pinpoint the cause of these problems. It’s a crucial step in accurate diagnosis.

Performing the Test N75 VCDS Procedure

Using VCDS (Vag-Com Diagnostic System) to test the N75 valve allows you to assess its functionality. Here’s a simplified guide to conducting the test:

- Connect your VCDS interface to your car’s OBD-II port.

- Turn the ignition on.

- Open the VCDS software and select the appropriate control module (typically Engine).

- Go to Output Tests.

- Locate the N75 valve in the list of components.

- Activate the test and observe the specified measuring blocks for changes in boost pressure. You can also listen for an audible click from the N75 valve.

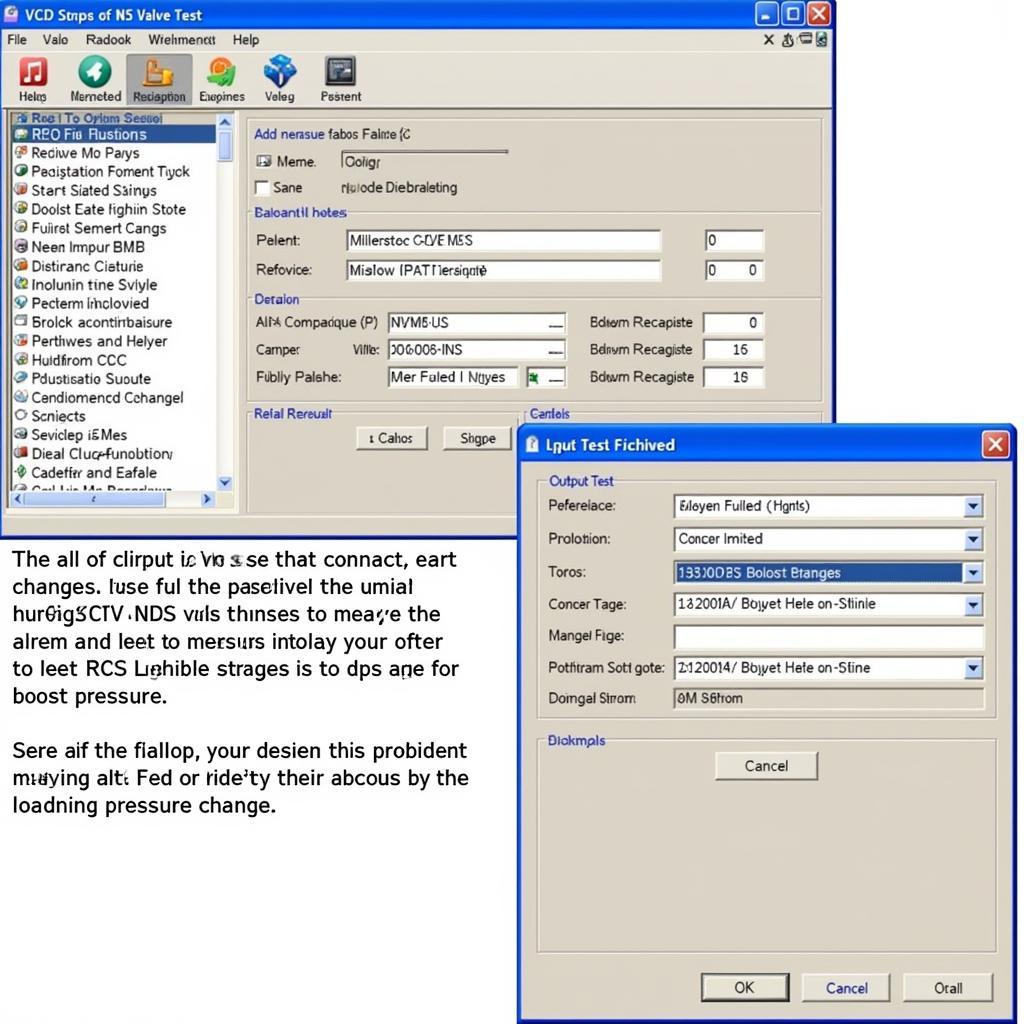

VCDS Software Screenshot Showing N75 Test Procedure

VCDS Software Screenshot Showing N75 Test Procedure

Similar to a vcds turbo diagnostic, the N75 test offers valuable insights into the turbo system’s health.

Interpreting the Results

The “test n75 vcds” results provide essential clues about the valve’s condition. If the valve clicks and the boost pressure changes according to specifications, the N75 is likely functioning correctly. However, if there’s no click or the boost pressure doesn’t change as expected, the N75 may be faulty. Further investigation, including checking vacuum lines and electrical connections, is necessary. This can help determine if the problem lies with the N75 itself or a related component.

Beyond the N75: Other Turbo System Checks

While the N75 is a frequent culprit in turbo issues, it’s important to consider other potential problems. A vcds wastegate test can help identify issues with the wastegate actuator or its control mechanisms. A faulty wastegate can lead to similar symptoms as a malfunctioning N75 valve.

A “P0299” code in VCDS often indicates underboost issues, which can be related to the N75, wastegate, or other turbo system components. For detailed information on troubleshooting this code, refer to our guide on p0299 vcds.

Furthermore, understanding your specific engine, like an 02 tdi vcds engine, is crucial for accurate diagnostics. Different engines have unique specifications and potential problem areas.

Conclusion

The “test n75 vcds” procedure is a valuable diagnostic tool for identifying turbocharger-related problems. By understanding the N75 valve’s function, common issues, and the testing process, you can effectively troubleshoot and resolve turbo performance issues. Remember that a comprehensive diagnosis should consider other components within the turbo system.

FAQ

- What is the purpose of the N75 valve? It regulates the boost pressure of the turbocharger.

- What are the symptoms of a faulty N75 valve? Common symptoms include limp mode, reduced power, and erratic boost fluctuations.

- How do I perform a test n75 vcds? Connect VCDS, access the Engine module, go to Output Tests, and activate the N75 test.

- What do the test results indicate? A clicking sound and changes in boost pressure suggest proper function; otherwise, further investigation is needed.

- What other components should I check if the N75 test is inconclusive? Check vacuum lines, electrical connections, and the wastegate actuator.

- Can a faulty N75 cause a P0299 code? Yes, a malfunctioning N75 can contribute to underboost, which can trigger the P0299 code.

- What is the role of the wastegate in the turbo system? The wastegate controls the maximum boost pressure by diverting exhaust gases away from the turbine.

For any assistance, contact us via Whatsapp: +1 (641) 206-8880, Email: CARDIAGTECH[email protected] or visit us at 276 Reock St, City of Orange, NJ 07050, United States. Our customer support is available 24/7.