Is your diesel engine showing signs of trouble? Poor fuel economy, rough idling, or excessive smoke could indicate a problem with your fuel injectors. Accurately diagnosing and addressing these issues is crucial for maintaining your engine’s performance and longevity. This is where VCDS (Vag-Com System) comes into play, offering a powerful diagnostic tool for inspecting and analyzing your diesel injectors.

Understanding VCDS and its Role in Injector Diagnostics

VCDS is a powerful diagnostic software suite developed specifically for vehicles in the Volkswagen Audi Group (VAG). It allows you to access and interpret the data from your car’s Engine Control Unit (ECU), essentially acting as the language bridge between you and your vehicle’s complex electronic systems.

When it comes to diesel injectors, VCDS provides crucial insights into their operation, allowing you to identify potential problems.

How to Check Injectors with VCDS: A Step-by-Step Guide

Before you begin, ensure you have the correct VCDS software version for your vehicle model and a compatible cable to connect to your car’s OBD-II port.

Here’s a general guide to checking injectors with VCDS:

- Connect and Run VCDS: Connect your VCDS interface to your car’s OBD-II port and your computer. Turn the ignition on but don’t start the engine. Launch the VCDS software and establish communication with your vehicle.

- Select Engine Control Module: Navigate to the “Select Control Module” section and choose “Engine” or the equivalent module for your specific vehicle.

- Access Measuring Blocks: Locate the “Measuring Blocks” function within the Engine module. This is where you can view live data streams from various engine sensors, including the fuel injectors.

- Identify Injector Measuring Blocks: Each injector will have a designated measuring block, often labeled as “Injector Quantity Deviation” or similar. Refer to your VCDS documentation or online resources to find the specific block numbers for your engine code.

- Monitor Injector Values: Observe the values displayed in the injector measuring blocks. These values typically represent the amount of fuel being delivered by each injector or any deviations from the expected range.

- Analyze the Results: Ideal injector values should be relatively close to each other, indicating a balanced fuel delivery. Significant deviations between injectors could suggest a problem with one or more injectors.

Note: This is a general guide, and the specific steps and measuring block numbers might vary depending on your vehicle model and year. Consult your VCDS documentation or reputable online forums for precise instructions for your car.

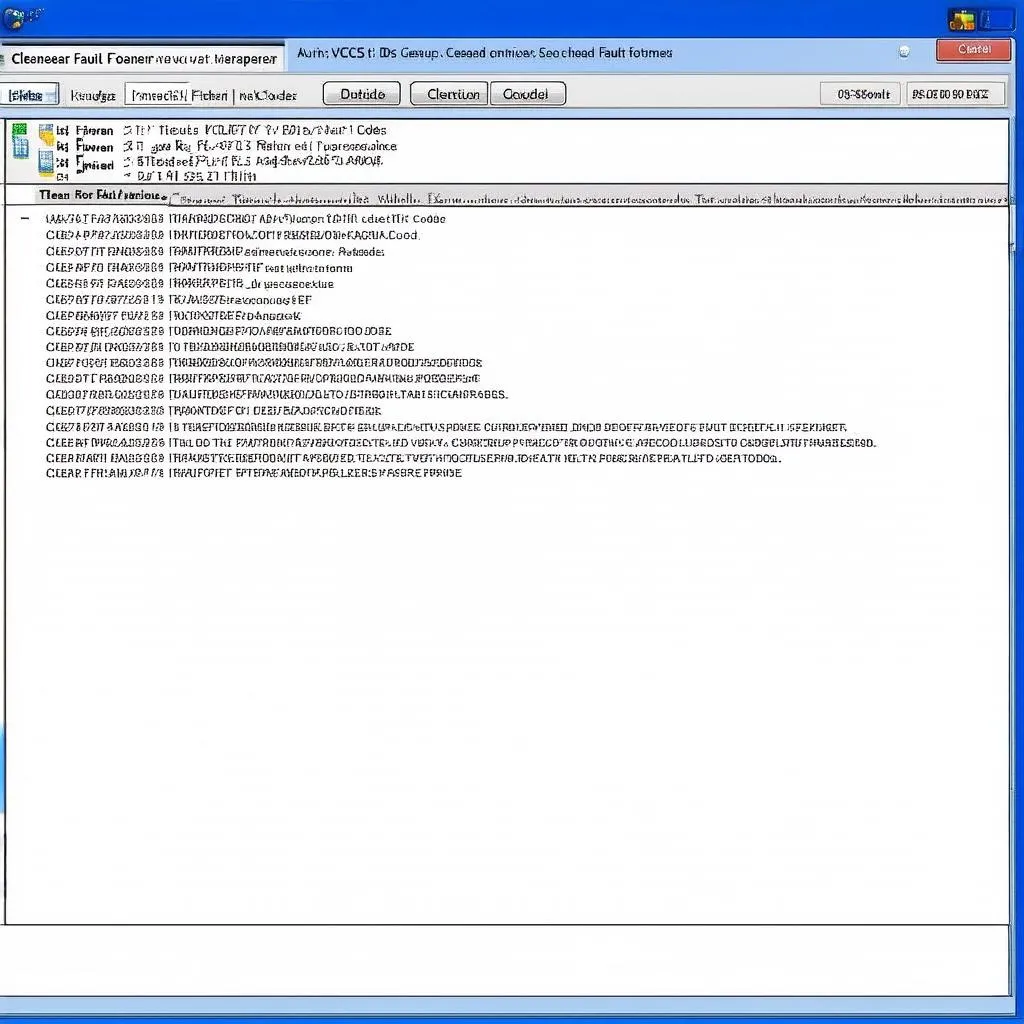

VCDS Injector Test

VCDS Injector Test

Interpreting VCDS Injector Readings

What do the numbers in those measuring blocks actually mean?

- Injector Quantity Deviation: This value indicates how much each injector’s fuel delivery deviates from the average of all injectors. A large deviation, either positive or negative, can point to a problematic injector.

- Injection Timing: Some VCDS versions display injection timing data, which shows when each injector is firing. This can help diagnose issues with injector timing, which can impact performance and emissions.

Expert Insight: “Analyzing injector deviation values is crucial for pinpointing fuel delivery imbalances. Even slight variations can lead to noticeable performance issues,” says automotive engineer and author, David Thompson, in his book “Advanced Diesel Engine Diagnostics.”

Common Injector Problems Identifiable Through VCDS

VCDS can help diagnose a range of injector problems, including:

- Clogged Injectors: A clogged injector will restrict fuel flow, leading to a lower than average quantity deviation value.

- Leaking Injectors: Leaking injectors can cause excessive fuel delivery, resulting in a higher than average deviation.

- Electrical Faults: VCDS can often detect electrical problems with injector circuits, such as open circuits or shorts.

Advantages of Using VCDS for Injector Diagnostics

- In-Depth Diagnostics: VCDS provides a more comprehensive view of your injectors compared to generic OBD-II scanners.

- Cost-Effective: VCDS can save you money on expensive dealership visits for diagnostics.

- Preventative Maintenance: Regularly monitoring your injectors with VCDS can help identify potential problems early on.

Limitations of VCDS in Injector Diagnostics

While a powerful tool, VCDS has some limitations:

- Requires Technical Knowledge: Interpreting VCDS data accurately requires a basic understanding of diesel engine systems.

- Cannot Physically Test Injectors: VCDS can only analyze data; it cannot physically test or repair injectors.

FAQs about VCDS and Injector Checks

Q: Can I use VCDS to code new injectors?

A: Yes, in many cases, VCDS allows you to adapt or code new injectors to your engine’s ECU.

Q: What should I do if VCDS detects an injector problem?

A: If an injector problem is identified, it’s best to consult with a qualified mechanic specializing in diesel engines. They can perform further tests and recommend the appropriate repairs.

Diesel Injector Cleaning

Diesel Injector Cleaning

Conclusion

VCDS offers a valuable toolset for diesel engine owners to monitor and diagnose potential injector problems. By understanding how to use VCDS and interpret its readings, you can take a proactive approach to maintaining your diesel engine’s health and performance. Remember, if you suspect injector issues, always seek the expertise of a qualified diesel mechanic for proper diagnosis and repair.

For a wide range of automotive diagnostic tools and resources, visit CARDIAGTECH.