The Warn RT25 brake diagram is a crucial resource for anyone who owns or maintains a Warn RT25 winch. This robust winch, popular for its reliability and power, relies on a well-maintained braking system for safe and efficient operation. Whether you’re a seasoned off-road enthusiast or a newcomer to the world of winching, a firm grasp of the brake diagram can be invaluable for troubleshooting issues and ensuring optimal performance.

This article will delve into the intricacies of the Warn RT25 brake diagram, empowering you with the knowledge to confidently tackle brake-related maintenance and repairs.

Decoding the Warn RT25 Brake System

The braking system on a Warn RT25 winch is a vital safety feature. It’s responsible for holding the load securely when the winch is not actively spooling, preventing uncontrolled unwinding. Understanding the components and their interplay as illustrated in the brake diagram is essential.

Key Components and Their Functions:

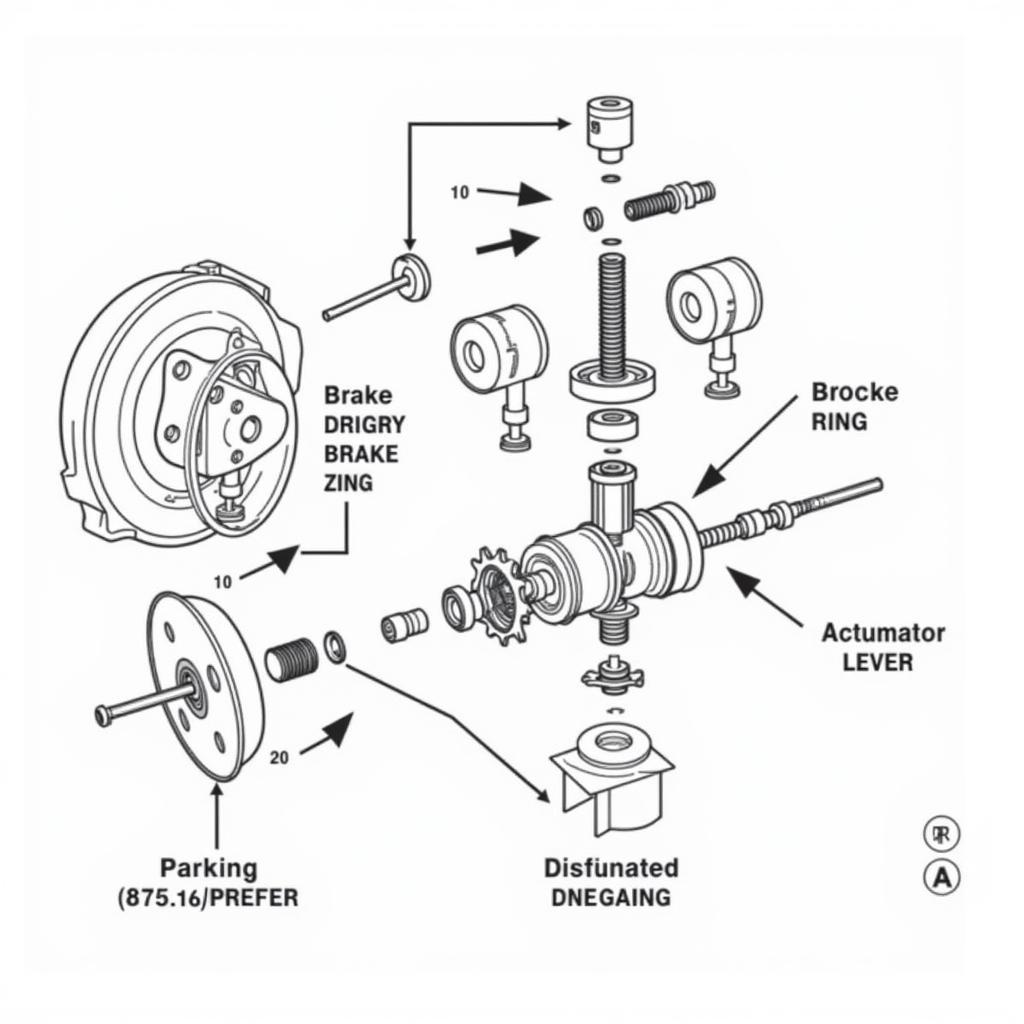

- Brake Ring: This component is directly responsible for generating the braking force. It’s typically made of high-friction material and interfaces with the brake drum.

- Brake Drum: An integral part of the winch drum assembly, the brake drum provides the contact surface for the brake ring.

- Brake Spring(s): These springs provide the necessary force to engage the brake when the winch is not in use. Their tension is crucial for effective braking action.

- Actuator: The actuator, often a lever or a sliding mechanism, is responsible for releasing the brake when you need to spool the winch.

Warn RT25 Brake Diagram Exploded View

Warn RT25 Brake Diagram Exploded View

Common Warn RT25 Brake Problems and Solutions

Like any mechanical system, the Warn RT25 brake can encounter issues over time. Familiarizing yourself with these common problems can save you time and frustration when troubleshooting.

- Winch Won’t Hold a Load: This is often a sign of worn brake linings or a problem with the brake spring tension.

- Winch is Hard to Release: A sticking brake actuator, a jammed brake ring, or excessive spring tension can make it difficult to disengage the brake.

- Grinding Noise During Operation: This could indicate a worn brake ring, debris trapped in the brake assembly, or improper lubrication.

Utilizing the Warn RT25 Brake Diagram for Troubleshooting

The Warn RT25 brake diagram is an invaluable tool for diagnosing and addressing brake-related issues. It provides a visual guide to the brake assembly, allowing you to:

- Identify Components: Easily locate and name each part of the brake system.

- Understand Relationships: Visualize how the components interact and influence each other.

- Trace Force Flow: Follow the path of force as it’s applied and released within the brake mechanism.

“When diagnosing a brake problem, always consult the Warn RT25 brake diagram,” advises veteran mechanic and off-road enthusiast, Mark Stevenson. “It’s your roadmap to understanding how the system works and pinpointing the root cause of any issues.”

Adjusting Brake Spring Tension

Adjusting Brake Spring Tension

Conclusion

The Warn RT25 brake diagram is an indispensable resource for anyone looking to maintain, troubleshoot, or repair their winch’s braking system. By understanding its components, function, and common issues, you can ensure the safe and reliable operation of your winch for years to come. Remember to consult your winch’s user manual for specific instructions and safety precautions.