A “warn winch brake” is a critical safety component designed to prevent unintentional spooling or unwinding of your winch cable. When functioning correctly, it locks the drum securely in place when not in use. However, various factors can cause a warn winch brake to malfunction, leading to potential safety hazards and operational issues. This comprehensive guide aims to shed light on the workings of a warn winch brake, common problems associated with it, and effective troubleshooting steps to resolve those issues.

Warn winch brake assembly diagram

Warn winch brake assembly diagram

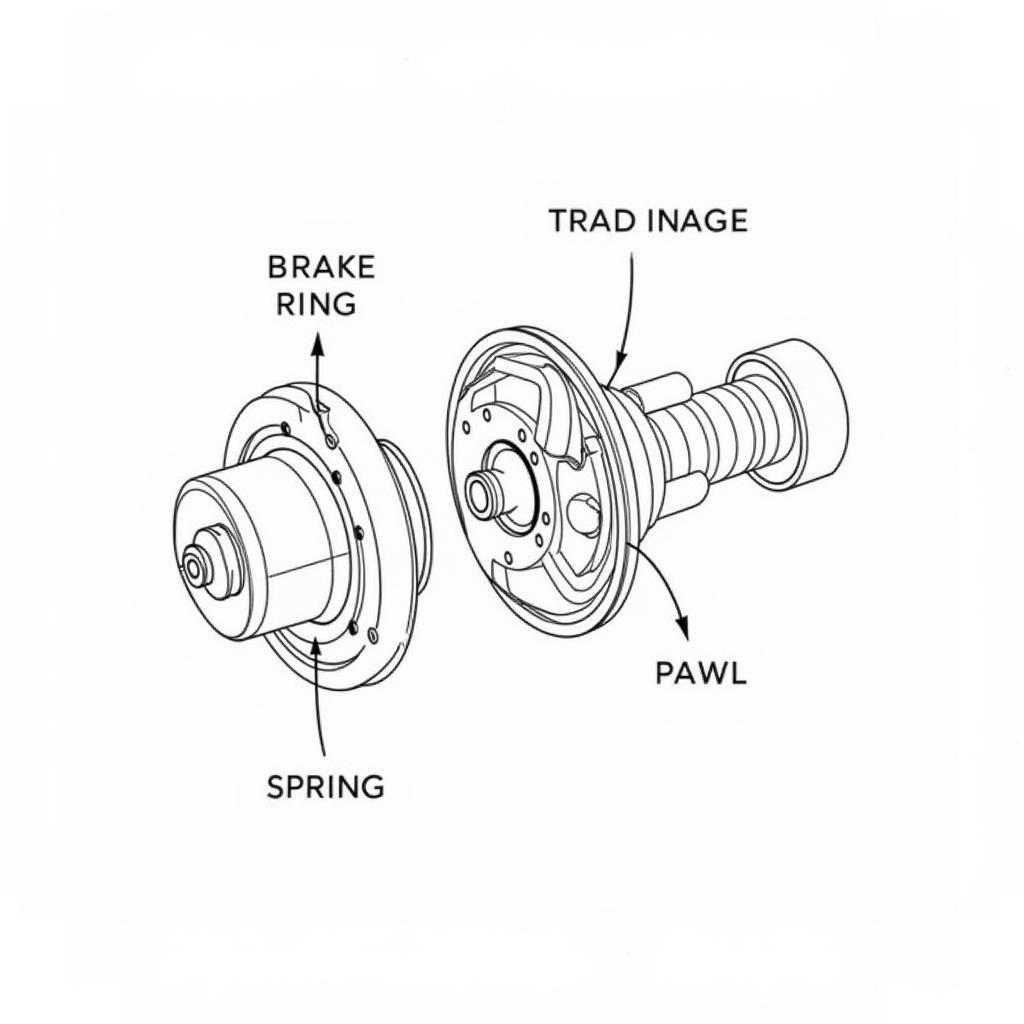

How a Warn Winch Brake Works

A warn winch brake typically operates on a mechanical principle using a series of components working in sync. The core of the system is a spring-loaded pawl mechanism that engages with teeth on a brake ring directly connected to the winch drum.

When the winch is not in use, the spring pushes the pawl into the teeth of the brake ring, preventing the drum from rotating. Conversely, when you activate the winch, the pulling force overcomes the spring tension, disengaging the pawl and allowing the drum to rotate freely and reel in or out the cable.

Common Warn Winch Brake Problems

Several issues can arise with your warn winch brake, often manifesting as:

-

Winch Free Spooling: The most common problem is the winch freely spooling cable even when not engaged. This usually points to a faulty brake mechanism, often caused by a worn-out brake ring, a damaged pawl, or a weakened spring.

-

Winch Hard to Engage: If your winch struggles to engage or disengage smoothly, it could be due to a sticking pawl, often caused by dirt, debris, or corrosion buildup within the brake assembly.

-

Unusual Noise During Operation: Grinding, clicking, or squealing sounds during winching operations can indicate a problem with the brake. These noises often result from a worn-out brake ring, a misaligned pawl, or inadequate lubrication.

Worn-out warn winch brake pawl

Worn-out warn winch brake pawl

Troubleshooting Your Warn Winch Brake

Before you begin, remember to disconnect the power to your winch and wear appropriate safety gear.

1. Inspect the Brake Assembly:

Begin by visually inspecting the brake assembly for any visible signs of damage, wear, or debris. Pay close attention to the brake ring, pawl, and spring. Look for missing teeth on the brake ring, cracks or bending on the pawl, and loss of tension in the spring.

2. Clean the Brake Assembly:

Over time, dirt, grime, and dried grease can accumulate within the brake assembly, hindering its operation. Use a brake cleaner and a stiff brush to thoroughly clean the brake ring, pawl, and surrounding components.

3. Lubricate the Brake Mechanism:

Proper lubrication is crucial for smooth brake engagement and disengagement. After cleaning, apply a thin layer of high-quality winch grease to the brake ring, pawl, and other moving parts within the assembly.

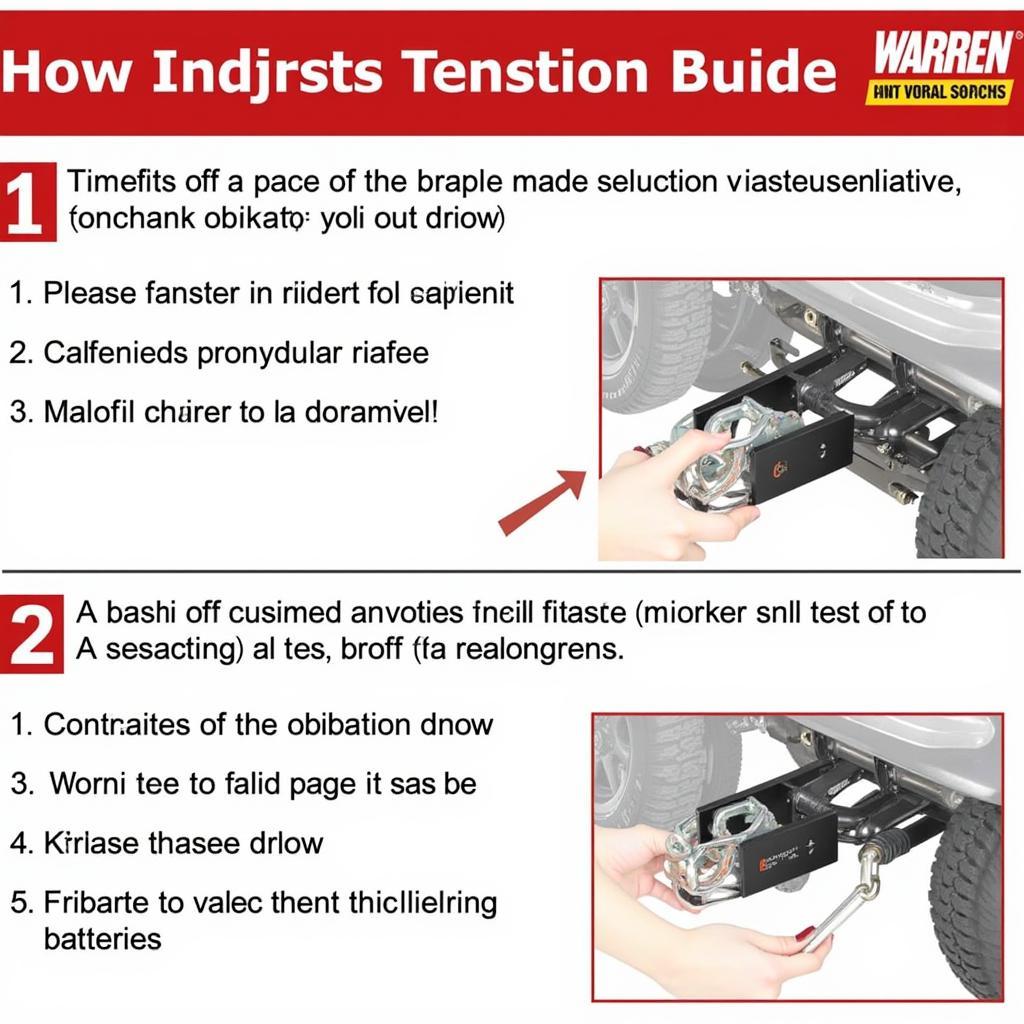

4. Adjust the Brake Assembly:

Some warn winch models feature an adjustment mechanism to fine-tune the brake engagement. Refer to your winch’s user manual for specific instructions on how to adjust the brake. Typically, it involves tightening or loosening a nut to increase or decrease the spring tension.

5. Replace Worn-Out Components:

If cleaning, lubrication, and adjustment fail to resolve the issue, the worn-out components likely need replacement. You can purchase replacement brake rings, pawls, and springs from authorized warn winch dealers or online retailers.

Adjusting warn winch brake tension

Adjusting warn winch brake tension

When to Seek Professional Help

While these troubleshooting steps can resolve many common warn winch brake problems, it’s crucial to recognize when to seek professional help. If you are uncomfortable working with mechanical components or if the issue persists after trying these steps, it’s best to consult a qualified warn winch technician. Attempting complex repairs without proper knowledge and tools can lead to further damage and potential safety hazards.

Expert Insights

“A well-maintained warn winch brake is not just about the smooth operation of your winch, it’s about safety,” says John Miller, a senior winch technician with over 20 years of experience. “Regular inspection and maintenance can prevent unexpected failures and ensure that your winch operates reliably when you need it the most.”

Conclusion

Understanding the workings of your warn winch brake and performing regular maintenance can significantly extend its lifespan and, most importantly, ensure your safety during winching operations. By following the troubleshooting steps outlined in this guide, you can address many common warn winch brake problems and keep your winch functioning reliably. However, always prioritize safety and seek professional help when needed.