A malfunctioning warn winch brake can be a serious safety hazard. This guide offers expert advice on diagnosing, repairing, and maintaining your warn winch brake to ensure optimal performance and safety. We’ll delve into common issues, troubleshooting techniques, and preventive maintenance to keep your winch operating smoothly.

Understanding the Warn Winch Brake

The warn winch brake is a crucial safety feature that prevents uncontrolled unwinding of the winch drum. It works by engaging automatically when the winch motor is not powered. A faulty brake can lead to dangerous situations, especially when carrying heavy loads. This is why regular inspection and maintenance of your warn winch brake is essential.

Why is a functional brake so critical? Imagine descending a steep incline with a heavy load. A failing brake could cause the load to accelerate uncontrollably, resulting in potential damage or injury. Proper maintenance can prevent such scenarios and ensure your safety.

Common Warn Winch Brake Problems

Several issues can affect the performance of your warn winch brake. These include:

- Brake slippage: The brake fails to hold the load, resulting in slow unwinding.

- Brake sticking: The brake remains engaged even when the winch motor is powered.

- Noisy brake: Grinding or squeaking sounds coming from the brake assembly.

- Complete brake failure: The brake does not engage at all, leading to free spooling.

Identifying the specific problem is crucial for effective warn winch brake repair. Let’s explore some troubleshooting techniques to pinpoint the cause of your brake issues.  Troubleshooting a Warn Winch Brake

Troubleshooting a Warn Winch Brake

Troubleshooting and Repairing Your Warn Winch Brake

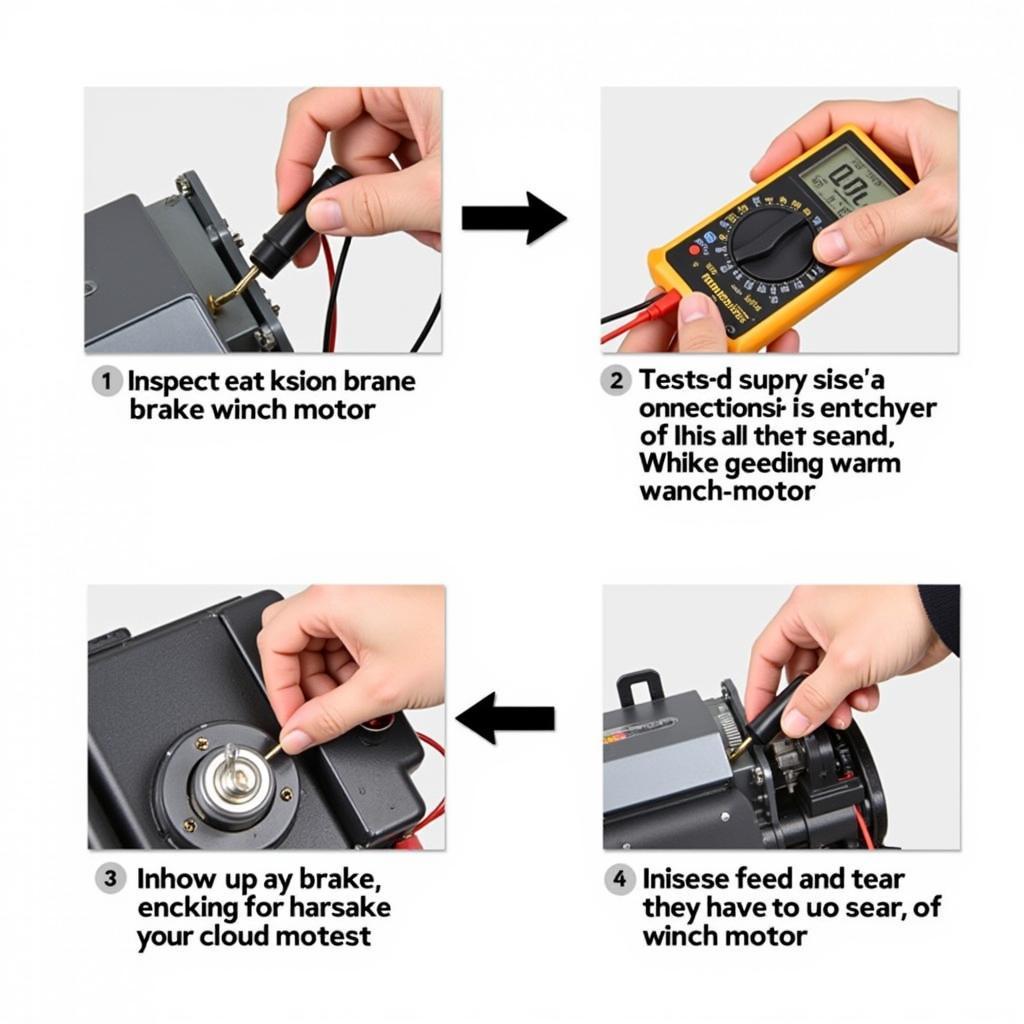

Before attempting any warn winch brake repair, disconnect the winch from the power source and ensure the vehicle is parked on a level surface. Safety should always be your top priority. remove brake warn winch will guide you through the process.

Diagnosing the Problem

- Inspect the brake drum and shoes: Look for signs of wear, damage, or contamination.

- Check the brake actuating mechanism: Ensure it’s functioning correctly and not obstructed.

- Test the electrical connections: Use a multimeter to verify the winch motor and brake solenoid are receiving power.

Once you’ve identified the issue, you can proceed with the appropriate repair.

Repairing the Brake

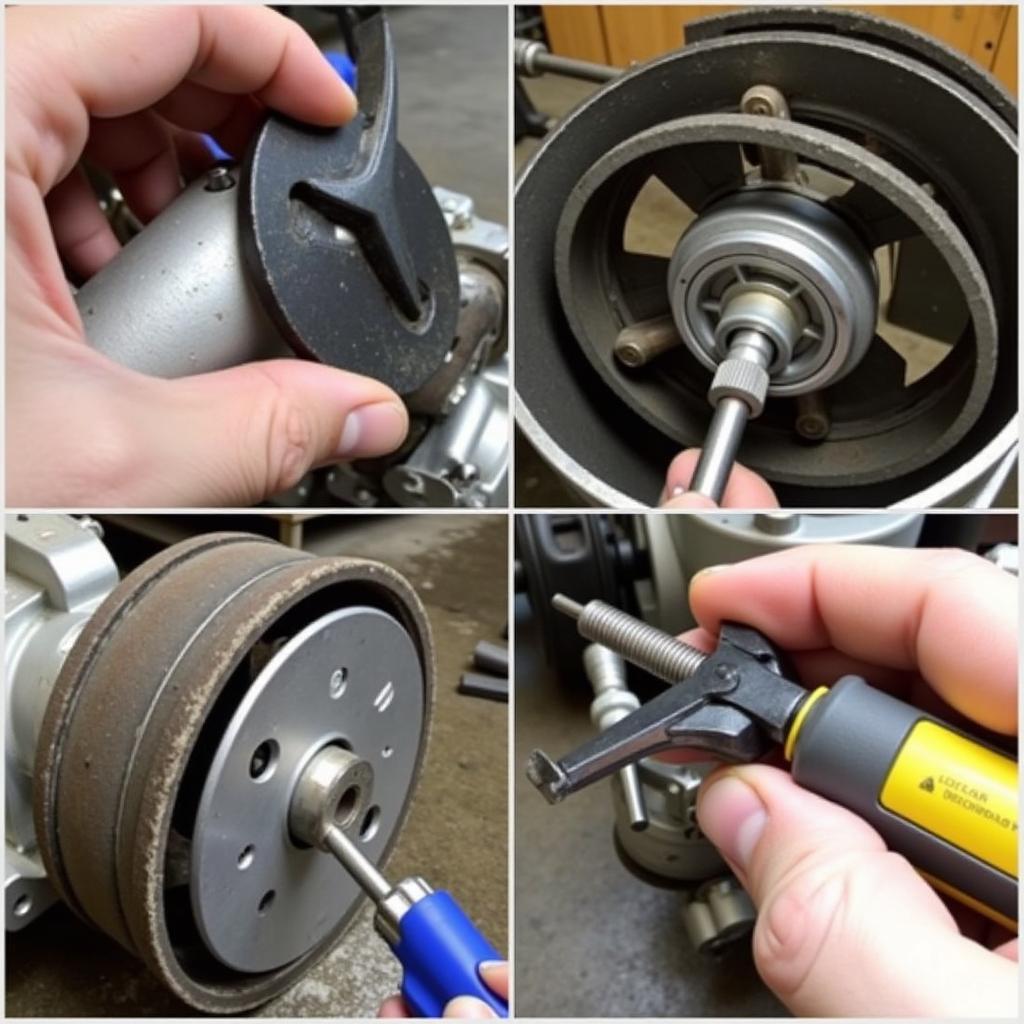

Depending on the problem, the repair might involve:

- Cleaning and adjusting the brake: This can often resolve minor issues like sticking or noise. warn 8274 winch brake rebuild offers step by step instructions.

- Replacing worn or damaged parts: Brake shoes, springs, and other components can be replaced to restore proper function. You might run into issues like those found in warn 8274 brake wont come apart, but with patience, you can often resolve these.

- Rebuilding the entire brake assembly: In cases of severe damage or extensive wear, a complete rebuild might be necessary.

Remember, if you’re not comfortable performing the repairs yourself, seek assistance from a qualified mechanic.  Warn Winch Brake Repair

Warn Winch Brake Repair

Preventing Warn Winch Brake Issues

Regular maintenance can significantly extend the lifespan of your warn winch brake and prevent costly repairs. Here are a few preventative measures:

- Regularly inspect the brake: Check for wear, damage, or contamination.

- Keep the brake clean and lubricated: This will prevent sticking and ensure smooth operation.

- Avoid overloading the winch: This can put excessive strain on the brake and lead to premature failure. You may experience something similar to this scenario warn winch brake doesnt hold winding opposite direction.

- Store the winch properly: Protect it from the elements to prevent corrosion and damage.

Conclusion

Maintaining a properly functioning warn winch brake is crucial for safe and reliable winching operations. By understanding the common problems, implementing effective troubleshooting techniques, and practicing preventative maintenance, you can keep your winch operating smoothly and minimize the risk of potential hazards. Regular inspection and timely warn winch brake repair ensure your safety and the longevity of your equipment. Don’t forget to also check your other safety systems like your toyota seat belt warning sound.