A “warn winch drum brake” is a crucial safety feature found in most modern winches. This brake prevents the winch drum from unwinding uncontrollably when a load is applied, ensuring safe and secure operation. However, like any mechanical component, warn winch drum brakes can sometimes encounter issues. This article will guide you through common problems, diagnostics, and solutions, helping you get your winch back to safe and optimal working condition.

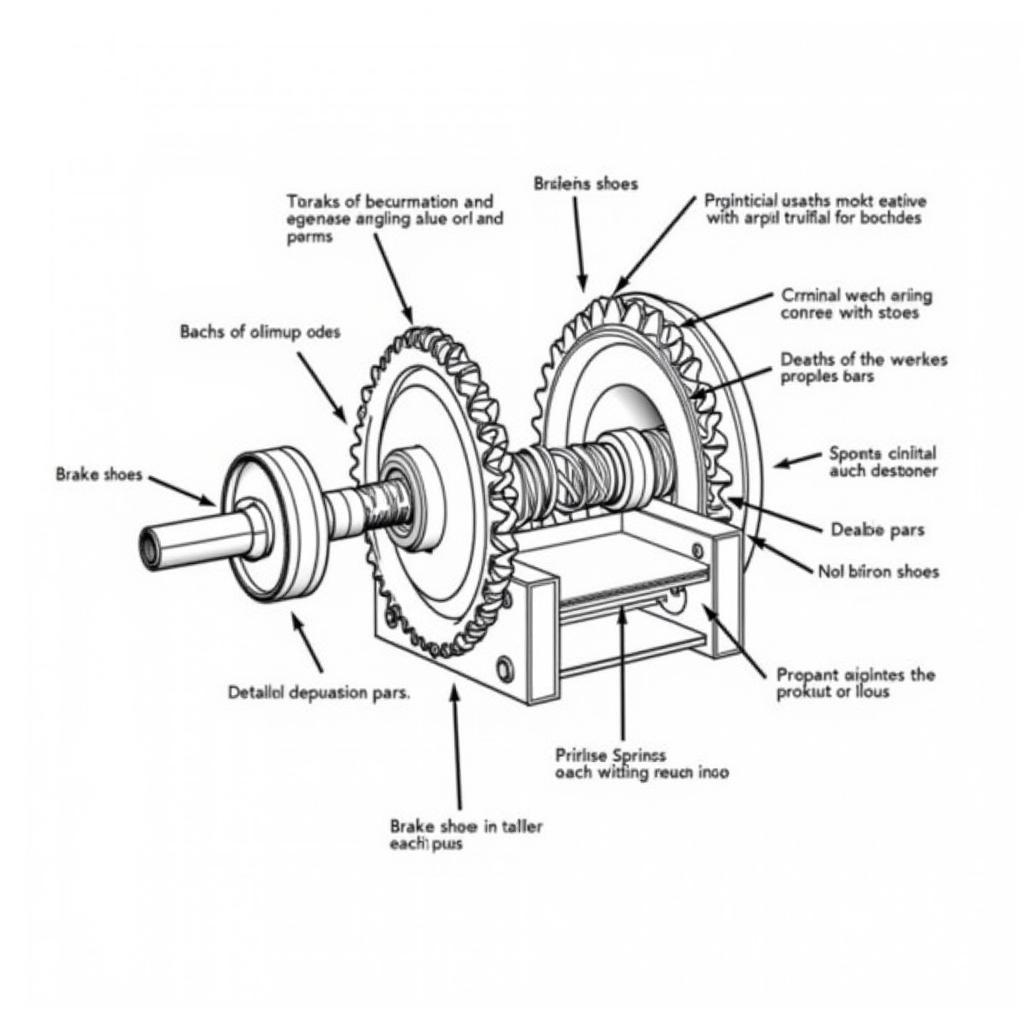

Warn Winch Drum Brake Components

Warn Winch Drum Brake Components

Understanding Your Warn Winch Drum Brake

Before diving into troubleshooting, it’s essential to understand the basic mechanics of your warn winch drum brake. Most winches employ an automatic brake system integrated into the drum. When the winch is not in use or under load, the brake remains engaged, preventing the drum from spinning. When you power the winch in, the brake automatically disengages, allowing the drum to rotate and wind the cable. As soon as the power is cut off, the brake automatically re-engages, holding the load securely.

Common Warn Winch Drum Brake Problems

Several issues can arise with a warn winch drum brake, affecting its performance and safety. Here are some of the most common ones:

- Winch slipping under load: If your winch struggles to hold a load or the cable slowly unwinds even when the winch is not powered, it indicates a slipping brake.

- Winch difficult to free spool: Difficulty in disengaging the brake and freely unwinding the cable could signal a problem with the brake mechanism.

- Unusual noises during operation: Grinding, squealing, or scraping noises when winching in or out can indicate brake shoe wear, misalignment, or a lack of lubrication.

- Visible signs of wear: Inspecting the brake components for excessive wear, damage, or missing parts is crucial.

Diagnosing the Problem

Identifying the root cause of the issue is essential for effective repair. Here’s a step-by-step approach to diagnose your warn winch drum brake:

-

Visual Inspection: Begin by visually inspecting the brake components. Look for signs of wear on the brake shoes, drum surface, springs, and the activation mechanism. Check for any loose, damaged, or missing parts.

-

Check for Free Spooling: Disengage the clutch on your winch to allow for free spooling. The drum should rotate smoothly without any resistance. If you encounter difficulty or hear unusual noises, the brake might be the culprit.

Adjusting Warn Winch Drum Brake

Adjusting Warn Winch Drum Brake

-

Adjust the Brake: Most warn winches offer a way to adjust the brake engagement. Refer to your winch’s user manual for specific instructions. In most cases, you can adjust the brake using an external screw or nut. Try tightening the brake incrementally while checking for improvements in holding power.

-

Test Under Load: After adjustments, carefully test the winch with a light load to ensure the brake engages and holds effectively. Never exceed the winch’s rated capacity.

Solutions and Repairs

Once you’ve identified the problem with your warn winch drum brake, here are some potential solutions:

- Brake Adjustment: If you experience slight slipping or difficulty free spooling, a simple brake adjustment might resolve the issue. Refer to your winch’s user manual for the correct procedure.

- Brake Shoe Replacement: Worn-out brake shoes can significantly impact performance and safety. If you notice excessive wear, replace them with genuine Warn parts designed for your winch model.

- Lubrication: Proper lubrication is vital for smooth brake operation. Consult your user manual for recommended lubricants and lubrication points.

- Component Replacement: Damaged or broken components like springs, adjusters, or the activation mechanism might require replacement. Again, using genuine Warn parts ensures compatibility and optimal performance.

- Professional Service: For complex issues or if you’re uncomfortable working on the winch yourself, seek assistance from a qualified Warn winch service center.

Preventing Future Issues

Regular maintenance is key to ensuring the longevity and reliable performance of your warn winch drum brake:

- Regular Inspection: Periodically inspect your winch for any visible signs of wear, damage, or loose components, particularly after demanding use.

- Cleaning and Lubrication: Keep your winch clean and lubricated according to the manufacturer’s recommendations.

- Proper Spooling: Always ensure the winch cable is neatly wound onto the drum under tension. Avoid loose or uneven spooling, which can damage the cable and brake.

- Load Management: Never exceed the winch’s rated capacity. Overloading can lead to premature wear and potential brake failure.

Conclusion

A properly functioning warn winch drum brake is paramount for safety and efficient winching operations. Understanding the common issues, implementing preventive maintenance practices, and addressing problems promptly will ensure your winch remains a reliable tool for years to come. Remember, safety should always be the top priority when operating any winch equipment. If you encounter persistent issues or have any doubts, consult your winch’s user manual or seek professional assistance from a qualified Warn service center.