Dealing with a stubborn Warner 2-piece brake clutch where the lower half refuses to separate? You’re not alone. This common issue can bring your vehicle to a standstill, but understanding the causes and solutions can get you back on the road quickly. Whether you’re a seasoned mechanic or a DIY enthusiast, this guide will walk you through the steps to diagnose and fix the problem.

Common Causes of a Stuck Lower Half

Before jumping into solutions, it’s crucial to identify the root cause. Here are some common culprits:

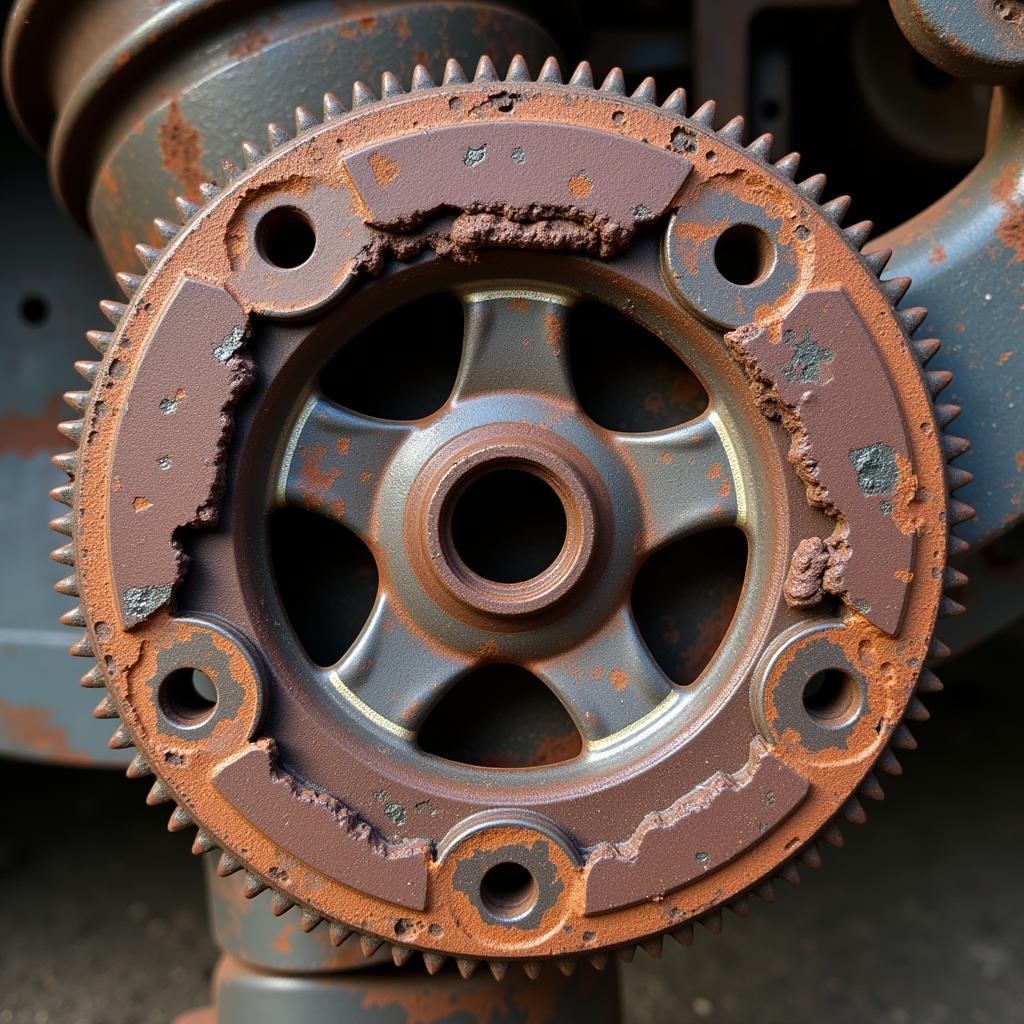

- Corrosion and Rust: The most frequent offender, especially in areas with high humidity or exposure to road salt. Corrosion can bind the clutch components together.

- Worn-out Components: Over time, the clutch’s moving parts, like the release bearing or pilot bearing, can wear down, leading to increased friction and sticking.

- Misalignment: Incorrect installation or impact damage can cause the clutch assembly to misalign, making separation difficult.

- Hydraulic Issues: Problems with the clutch master cylinder or slave cylinder can result in insufficient hydraulic pressure to disengage the clutch properly.

Troubleshooting and Solutions

Follow these steps to troubleshoot and resolve the issue:

-

Visual Inspection: Begin by visually inspecting the clutch assembly for any obvious signs of damage, corrosion, or fluid leaks.

Rusted Clutch Components

Rusted Clutch Components

-

Check for Hydraulic Issues: Inspect the clutch master cylinder and slave cylinder for leaks or damage. Ensure the fluid reservoir is full and the fluid is at the correct level.

Clutch Fluid Reservoir Inspection

Clutch Fluid Reservoir Inspection

-

Lubrication: Apply a generous amount of penetrating oil or a specialized clutch lubricant to the splines where the two halves of the clutch connect. Allow the lubricant to penetrate for several hours or overnight.

-

Gentle Persuasion: After lubrication, use a rubber mallet or a block of wood and a hammer to gently tap the lower half of the clutch. Avoid using excessive force, as this can damage the components.

“When freeing a stuck clutch, patience is key. Avoid using brute force, which can lead to costly repairs. Start with gentle tapping and gradually increase force if needed,” advises John Miller, a senior automotive engineer with over 20 years of experience.

-

Seek Professional Help: If the problem persists, it’s crucial to seek professional assistance. A qualified mechanic can diagnose the issue accurately and perform necessary repairs or replacements.

“Attempting to force the clutch apart without proper knowledge and tools can result in further damage. In some cases, internal components may need replacement, requiring professional expertise,” cautions Miller.

Preventive Measures

Preventing future sticking issues is crucial for maintaining a healthy clutch system:

- Regular Inspections: Inspect your clutch system regularly, especially during routine maintenance, for any signs of wear, damage, or fluid leaks.

- Timely Lubrication: Periodically lubricate the clutch splines with a suitable lubricant to prevent rust and corrosion.

- Proper Installation: Ensure the clutch is installed correctly by a qualified mechanic. Proper alignment and torque specifications are critical.

- Address Issues Promptly: If you experience any clutch-related problems, address them immediately to prevent further damage.

Conclusion

A stuck lower half on your Warner 2-piece brake clutch can be a frustrating experience, but understanding the causes and solutions can get you back on the road with minimal downtime. Remember to prioritize safety and seek professional help when needed. By following these tips and performing regular maintenance, you can extend the life of your clutch system and avoid unexpected breakdowns.