The Warner clutch brake assembly is a critical component in many industrial and automotive applications, responsible for smooth engagement and disengagement of power transmission. When issues arise with this assembly, it can lead to performance problems, downtime, and safety hazards.

This comprehensive guide will delve into common problems associated with Warner clutch brake assemblies, providing you with the knowledge and remote diagnostic approaches to resolve them effectively.

Understanding the Warner Clutch Brake Assembly

Before we dive into troubleshooting, it’s essential to grasp the basics of this assembly. A Warner clutch brake assembly typically consists of a clutch and a brake integrated into a single unit. The clutch controls the connection between the driving and driven components, while the brake provides stopping power. These assemblies are known for their durability, reliability, and precise control, making them suitable for various demanding applications.

Common Warner Clutch Brake Assembly Problems

A range of issues can arise with Warner clutch brake assemblies, impacting performance and safety. Here are some common problems:

- Clutch Slipping: This occurs when the clutch fails to transmit the full torque from the input to the output shaft, leading to reduced power and potential overheating.

- Brake Drag: When the brake doesn’t release completely, it creates friction and resistance, resulting in energy loss, overheating, and premature wear.

- Noise and Vibration: Unusual noises like grinding, squealing, or chattering, along with excessive vibration, can indicate misalignment, wear, or damage within the assembly.

- Engagement and Disengagement Issues: Difficulty in engaging or disengaging the clutch or brake smoothly points to potential problems with the control system, actuators, or linkages.

Remote Diagnostic Approaches for Troubleshooting

As an automotive electrical technician specializing in remote diagnostics, I use advanced tools and techniques to identify and address Warner clutch brake assembly issues remotely. Here’s how:

-

Data Acquisition and Analysis: I remotely access the vehicle’s onboard diagnostic system (OBD-II) to gather real-time data on clutch and brake performance, including speed sensors, pressure readings, and error codes. Analyzing this data provides crucial insights into the assembly’s behavior.

-

Software Analysis and Reprogramming: Often, issues stem from software glitches or outdated firmware within the clutch or brake control modules. I can remotely access and analyze the software, identifying and rectifying any anomalies through reprogramming or updates.

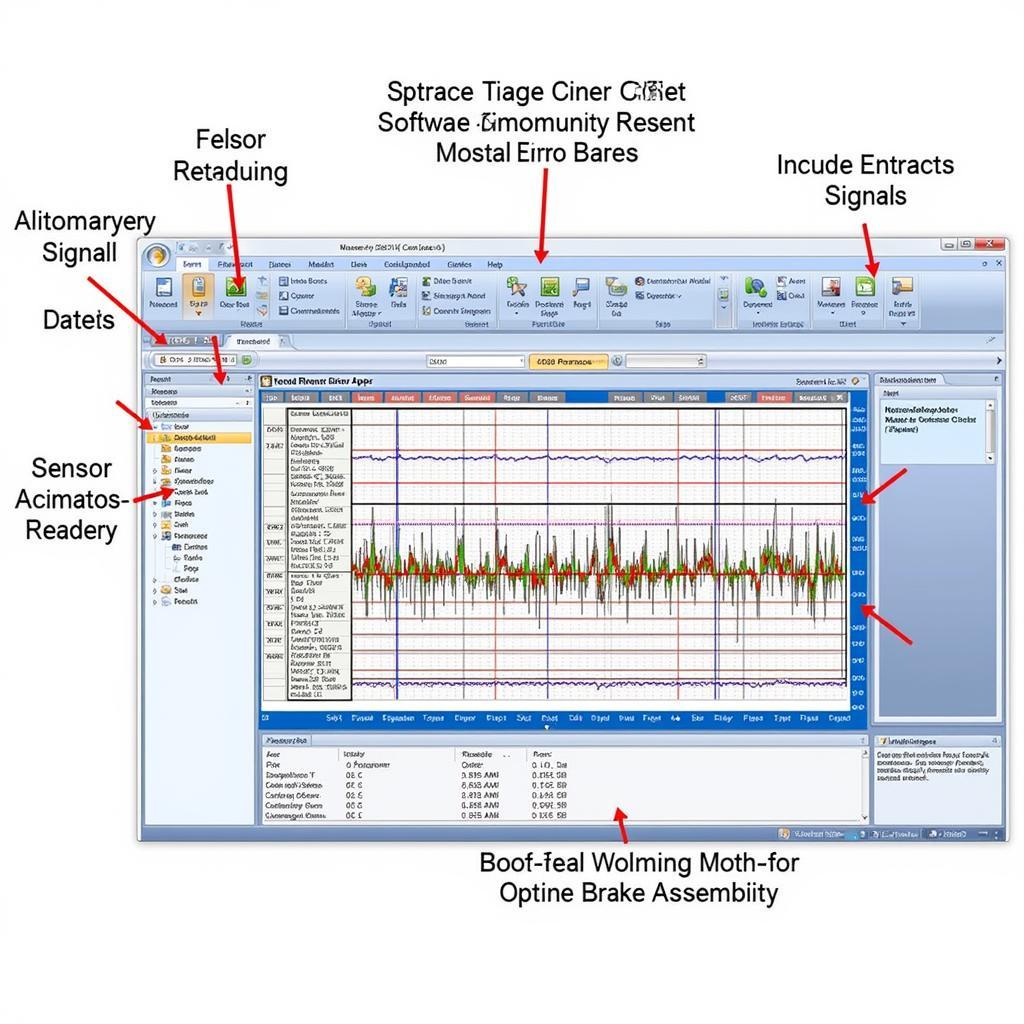

Remote Diagnostics Software Interface for Warner Assembly

Remote Diagnostics Software Interface for Warner Assembly

-

Visual Inspection (Remotely Guided): While physical access is ideal, I can guide technicians or vehicle owners through a visual inspection remotely. Utilizing video conferencing and clear instructions, I can identify external signs of damage, leaks, or wear on the assembly.

-

Component Testing (Remotely Guided): In some cases, remote testing of individual components within the assembly is necessary. I can guide technicians through specific tests, using multimeters or other diagnostic tools to check solenoids, sensors, and actuators for proper function.

Expert Insight

“In today’s connected world, remote diagnostics plays a pivotal role in quickly and efficiently resolving Warner clutch brake assembly issues,” says automotive electronics expert, David Miller. “By leveraging data analysis, software manipulation, and remote guidance, we can significantly reduce downtime and get vehicles back on the road faster.”

Preventive Maintenance for Optimal Performance

Regular preventive maintenance is key to prolonging the lifespan of your Warner clutch brake assembly and avoiding costly repairs.

- Regular Inspections: Conduct routine visual inspections for signs of wear, leaks, or damage to the assembly, including the clutch facings, brake linings, actuators, and linkages.

- Lubrication: Properly lubricate all specified points according to the manufacturer’s recommendations to reduce friction and wear.

- Adjustments: Ensure proper adjustments are made to the clutch and brake according to the manufacturer’s specifications to maintain optimal performance and prevent premature wear.

- Fluid Checks and Replacements: Regularly check and replace hydraulic fluids or air system components as recommended by the manufacturer to maintain system pressure and prevent contamination.

Conclusion

Troubleshooting Warner clutch brake assembly issues requires a systematic approach, and remote diagnostics has become an invaluable tool in this process. By understanding the common problems, utilizing remote diagnostic techniques, and adhering to preventive maintenance practices, you can ensure the optimal performance, reliability, and longevity of your Warner clutch brake assembly.

Remember, if you’re experiencing issues with your Warner clutch brake assembly, seeking assistance from a qualified automotive electrical technician specializing in remote diagnostics, like myself, is crucial for accurate diagnosis and effective resolution. For more information on Warner electric clutches and brakes, you can visit warner electric clutches and brakes.

FAQ

1. What are the signs of a failing Warner clutch brake assembly?

Common signs include clutch slipping, brake drag, unusual noises (grinding, squealing), excessive vibration, and difficulty engaging or disengaging the clutch or brake.

2. Can I drive my vehicle with a faulty Warner clutch brake assembly?

It’s not recommended to drive with a faulty assembly as it can lead to further damage, reduced performance, and safety hazards.

3. How often should I service my Warner clutch brake assembly?

Refer to your vehicle or equipment manufacturer’s recommendations for specific service intervals.

4. Can I replace parts of the assembly myself?

While some components might seem straightforward to replace, it’s best to consult a qualified technician to ensure proper installation and adjustments.

5. Are there any software updates available for my Warner clutch brake assembly?

Contact your vehicle or equipment manufacturer or a certified dealer to inquire about software updates for your specific assembly model.