The Warner clutch brake module is a critical component in many industrial and automotive applications, controlling precise stopping and starting motions. Understanding its function and how to troubleshoot potential issues is essential for maintaining optimal performance. warner clutch brake module um50-1020 plays a crucial role in various machinery and vehicles.

Understanding the Warner Clutch Brake Module

The Warner clutch brake module integrates the functionality of a clutch and a brake into a single unit. It’s commonly used in applications requiring quick and accurate engagement and disengagement, such as printing presses, packaging machines, and automated guided vehicles (AGVs). These modules often utilize electromagnetic actuation, providing precise control over the braking and clutching actions. This allows for smooth operation and minimizes wear and tear on connected components. Different models are available, catering to varying voltage and torque requirements. Choosing the right Warner clutch brake module is crucial for ensuring proper system operation and preventing premature failure.

Common Problems with Warner Clutch Brake Modules

Like any electromechanical device, Warner clutch brake modules can experience issues over time. Common problems include:

- Coil Failure: Overheating, voltage spikes, or general wear can lead to coil failure, preventing the module from engaging or disengaging.

- Wear of Friction Material: The friction material within the module is subject to wear, eventually reducing its effectiveness and requiring replacement.

- Mechanical Binding: Mechanical binding can occur due to misalignment, debris, or lubrication issues, hindering the module’s movement.

- Electrical Connection Problems: Loose or corroded connections can interrupt the power supply to the module, leading to erratic operation.

Troubleshooting Warner Clutch Brake Modules

Diagnosing the specific issue with a Warner clutch brake module involves a systematic approach. warner clutch brake troubleshooting often requires specialized diagnostic tools and knowledge.

- Visual Inspection: Begin by visually inspecting the module for any signs of physical damage, loose connections, or wear on the friction material.

- Electrical Testing: Use a multimeter to check the coil resistance and ensure proper voltage supply to the module.

- Mechanical Check: Inspect the mechanical linkage and ensure smooth movement without any binding or obstruction.

How to Test a Warner Clutch Brake Module Coil?

Testing the coil is crucial in diagnosing electrical issues. Connect a multimeter to the coil terminals and check the resistance. Compare the measured value with the manufacturer’s specifications. A significantly different reading indicates a potential coil failure.

What are the Symptoms of a Failing Warner Clutch Brake Module?

Symptoms of a failing Warner clutch brake module can include erratic engagement/disengagement, slipping, overheating, unusual noises, and complete failure to operate.

Solutions and Maintenance

Addressing issues with a Warner clutch brake module often involves replacing worn components or repairing electrical connections. Regular maintenance is essential to prolong the module’s lifespan. This includes:

- Lubrication: Proper lubrication of moving parts minimizes friction and wear.

- Cleaning: Regularly cleaning the module prevents debris buildup that can lead to mechanical binding.

- Inspection: Periodic inspection helps identify potential issues early on before they escalate.

warner electric brake and clutch components require regular maintenance for optimal performance.

“Regular maintenance is key to preventing unexpected downtime and extending the life of your Warner clutch brake module,” says John Smith, Senior Electrical Engineer at Industrial Automation Solutions.

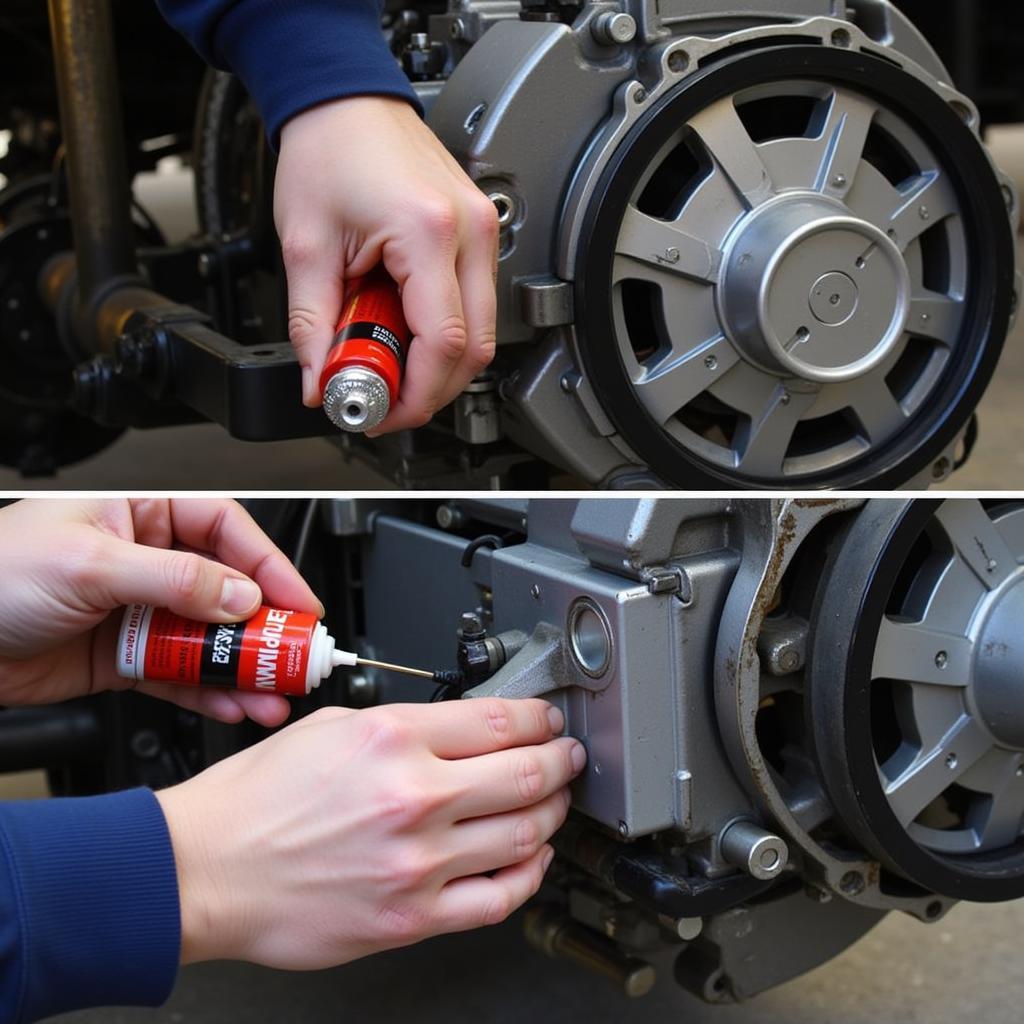

Technician Performing Maintenance on Warner Clutch Brake Module

Technician Performing Maintenance on Warner Clutch Brake Module

Conclusion

The Warner clutch brake module is a vital component in many industrial systems. Understanding its function, potential problems, and proper maintenance practices is crucial for ensuring smooth and efficient operation. By following the troubleshooting steps outlined above, you can identify and address issues effectively, minimizing downtime and maximizing productivity. Remember, regular maintenance and timely repairs are essential for extending the life of your Warner clutch brake module. warner clutch brake module um50-1020-90vdc is a specific model that might be relevant to your application. warner double c-face ac brake is another type of brake offered by Warner Electric.