Warner Electric brake clutches manufactured in China have become increasingly prevalent in the automotive industry. This guide delves into the key aspects of these components, from their functionality and applications to sourcing and troubleshooting. We’ll explore the benefits and challenges associated with choosing Chinese manufacturers and provide valuable insights for informed decision-making.

Understanding Warner Electric Brake Clutches

Warner Electric brake clutches are electromagnetic devices that combine the functions of a brake and a clutch. They are essential for precise control of motion and stopping power in various automotive applications. These clutches engage when energized, transmitting torque and disengaging when de-energized, applying the brake. Their compact design and quick response times make them ideal for demanding applications.

Functionality and Applications in Automotive Systems

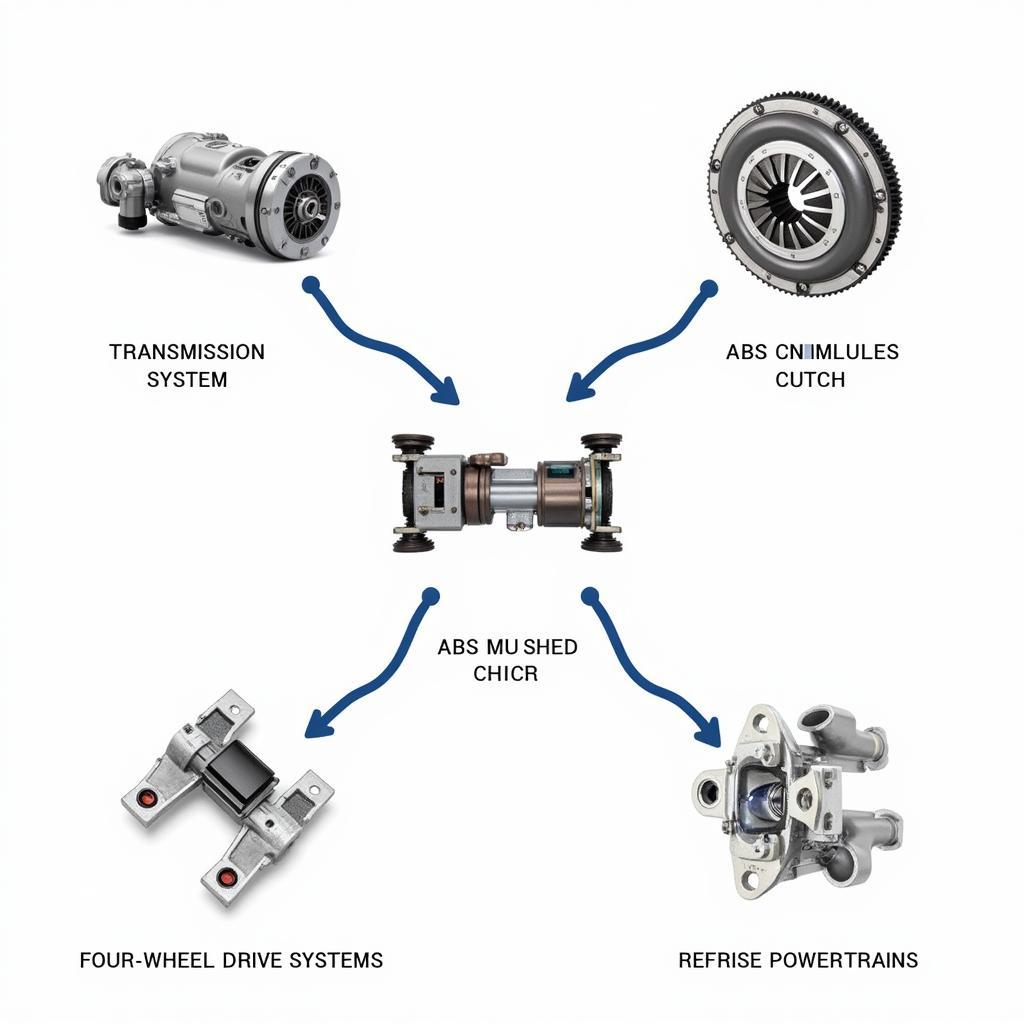

These clutches play a critical role in various automotive systems, including:

- Transmission Systems: Precise gear shifting and smooth power delivery.

- ABS and Traction Control: Modulation of braking force for enhanced safety.

- Four-Wheel Drive Systems: Engaging and disengaging drive axles for optimal traction.

- Hybrid and Electric Vehicles: Managing power flow between different drive components.

Warner Electric Brake Clutch Applications in Automotive Systems

Warner Electric Brake Clutch Applications in Automotive Systems

Sourcing Warner Electric Brake Clutches from China

China has become a significant player in the manufacturing of Warner Electric brake clutches. Sourcing from China offers potential cost advantages and a vast network of suppliers. However, it’s crucial to approach this process with careful consideration.

Navigating the Chinese Manufacturing Landscape

- Identifying Reputable Manufacturers: Conduct thorough research and due diligence to ensure quality and reliability.

- Verifying Certifications and Standards: Look for ISO certifications and adherence to international quality standards.

- Negotiating Pricing and Lead Times: Be prepared to negotiate and establish clear terms.

- Communication and Logistics: Effective communication and streamlined logistics are essential for a smooth procurement process.

Sourcing Warner Electric Brake Clutches from China

Sourcing Warner Electric Brake Clutches from China

Benefits and Challenges of Choosing Chinese Manufacturers

Choosing Warner electric brake clutch manufacturers China offers several advantages, primarily cost-effectiveness and high production capacity. However, potential challenges include quality control consistency, communication barriers, and intellectual property protection. Mitigating these challenges requires proactive measures like establishing clear quality control procedures and engaging reputable sourcing agents.

Troubleshooting Warner Electric Brake Clutches

Effective troubleshooting is crucial for maintaining optimal performance and minimizing downtime. Here are common issues and potential solutions:

- Clutch Slippage: This can be caused by worn friction material or insufficient coil voltage. Check the friction material and electrical connections.

- Overheating: Overheating can indicate excessive engagement or inadequate cooling. Ensure proper cooling and adjust engagement cycles as needed.

- Failure to Engage/Disengage: This can result from electrical faults, mechanical binding, or damaged components. Inspect wiring, mechanical linkages, and the clutch assembly.

Remote Diagnostics and Software Solutions

Remote diagnostics and software solutions can greatly enhance troubleshooting efficiency. These tools allow technicians to access real-time data and identify potential issues remotely. Software updates and calibrations can often be performed remotely, minimizing downtime and reducing repair costs.

Remote Diagnostics for Warner Electric Brake Clutches

Remote Diagnostics for Warner Electric Brake Clutches

Conclusion

Warner electric brake clutch manufacturers China present a significant opportunity for businesses seeking cost-effective solutions. By carefully navigating the Chinese manufacturing landscape and implementing robust quality control measures, businesses can leverage the benefits while mitigating the challenges. Understanding the functionality, applications, and troubleshooting procedures for these crucial components ensures optimal performance and longevity in automotive systems.

FAQ

- What are the key advantages of sourcing Warner Electric brake clutches from China? Cost-effectiveness and high production capacity are the primary advantages.

- What are the potential challenges of working with Chinese manufacturers? Potential challenges include quality consistency, communication barriers, and intellectual property protection.

- How can I identify reputable Warner Electric brake clutch manufacturers in China? Conduct thorough research, check certifications, and seek recommendations from industry professionals.

- What are common troubleshooting issues with these clutches? Common issues include slippage, overheating, and failure to engage/disengage.

- How can remote diagnostics help with troubleshooting? Remote diagnostics allow for real-time data analysis and remote software updates, minimizing downtime and repair costs.

- What are the primary applications of these clutches in automotive systems? Transmission systems, ABS, traction control, four-wheel drive systems, and hybrid/electric vehicle powertrains.

- What are the key considerations when negotiating with Chinese suppliers? Clearly define quality standards, payment terms, lead times, and communication protocols.