The Warner Electric Brake EM-180-20 is a vital component found in many trailers, ensuring reliable braking and safe towing. However, like any complex system, it can sometimes encounter issues. This guide will walk you through common problems with the Warner Electric Brake EM-180-20, explain how to diagnose them, and offer potential solutions.

Understanding the Warner Electric Brake EM-180-20

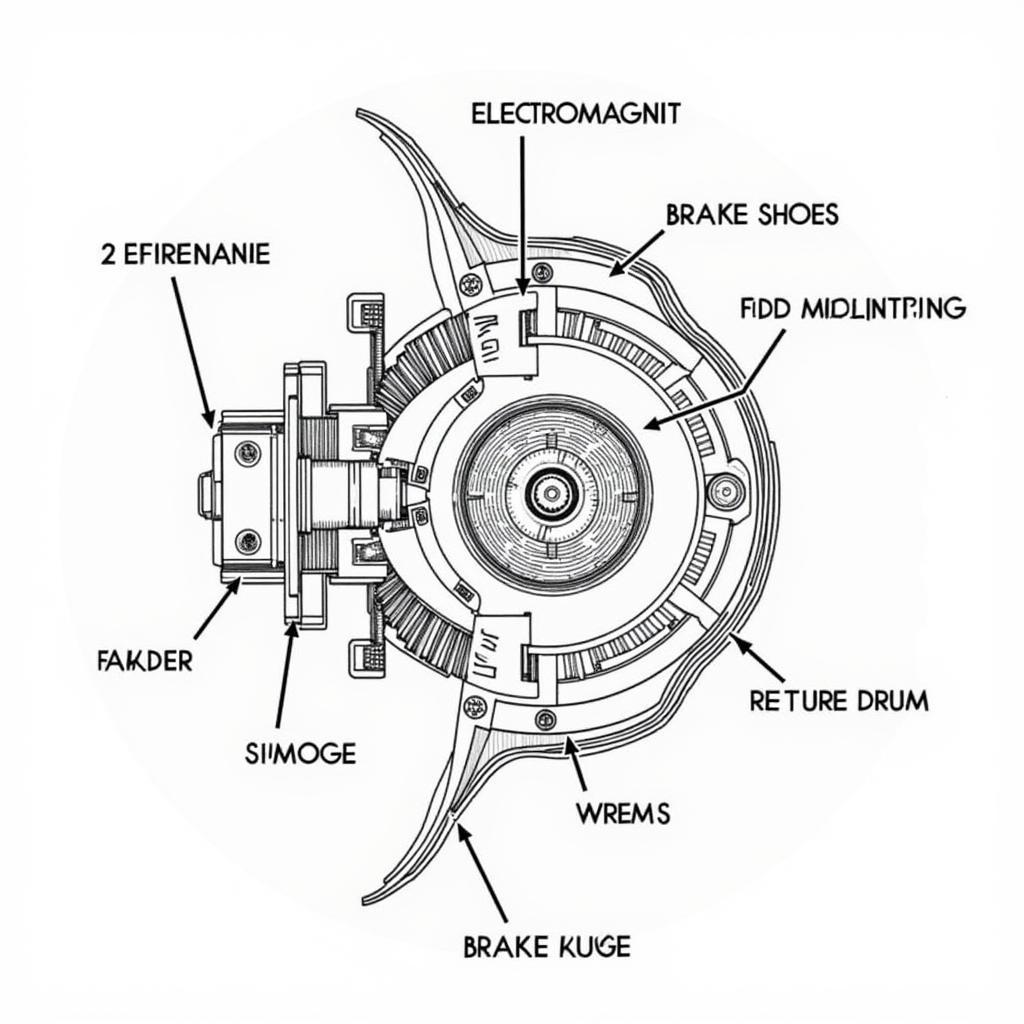

Before diving into troubleshooting, it’s crucial to understand the basic function of the EM-180-20. This electromagnetic brake assembly uses an electromagnet to activate the brake shoes, creating friction against the brake drum when the trailer brakes are applied. Its operation relies on a steady electrical current from the tow vehicle.

Warner Electric Brake EM-180-20 Components

Warner Electric Brake EM-180-20 Components

Common Problems and Solutions

Here are some common issues you might encounter with your Warner Electric Brake EM-180-20:

1. No Power to the Brake Assembly

Symptoms: The brake assembly fails to engage when the trailer brakes are applied.

Possible Causes:

- Blown fuse in the tow vehicle or trailer.

- Damaged or disconnected wiring between the tow vehicle and the trailer.

- Faulty brake away kit.

- Malfunctioning brake controller.

Troubleshooting Steps:

- Check the fuses: Locate the fuse related to the trailer brakes in both the tow vehicle and trailer fuse boxes. Replace any blown fuses.

- Inspect the wiring: Thoroughly examine the wiring harness connecting the tow vehicle and trailer, looking for any signs of damage, corrosion, or loose connections. Repair or replace damaged wiring as needed.

- Test the brake away kit: Ensure the brake away kit’s battery is charged and the unit is functioning correctly.

- Verify brake controller operation: Use a circuit tester or consult the brake controller manual to ensure it sends power to the trailer brakes when activated.

2. Weak or Uneven Braking Performance

Symptoms: The trailer brakes engage, but the braking force is insufficient or uneven on one side.

Possible Causes:

- Incorrectly adjusted brakes.

- Worn brake shoes or drums.

- Air gap between the electromagnet and brake drum is too large.

- Damaged or corroded brake components.

Troubleshooting Steps:

- Adjust the brakes: Consult your trailer’s owner’s manual for the proper brake adjustment procedure. Ensure the brake shoes make good contact with the drum when applied, but don’t drag.

- Inspect the brake shoes and drums: Check the brake shoes for excessive wear and the drums for scoring or damage. Replace any worn or damaged components.

- Check the air gap: The air gap between the electromagnet and brake drum should fall within the manufacturer’s specifications. Adjust as needed.

- Inspect for damage or corrosion: Examine all brake components, including the backing plate, springs, and hardware for any signs of damage or corrosion. Replace any compromised parts.

Adjusting the Warner Electric Brake EM-180-20

Adjusting the Warner Electric Brake EM-180-20

3. Overheating Brakes

Symptoms: The brakes overheat excessively, leading to reduced braking performance or potential damage.

Possible Causes:

- Riding the brakes.

- Overloaded trailer.

- Seized brake components.

- Incorrectly adjusted brakes.

Troubleshooting Steps:

- Avoid riding the brakes: Maintain a safe distance from other vehicles and anticipate braking needs to avoid prolonged brake application.

- Check trailer weight: Ensure the trailer’s load is within its specified weight capacity.

- Inspect for seized components: Check for any seized brake components, such as the wheel cylinders or parking brake mechanism. Free up or replace any seized parts.

- Readjust the brakes: Ensure the brakes are properly adjusted to prevent dragging and excessive heat buildup.

4. Noise Coming from the Brake Assembly

Symptoms: Grinding, squealing, or scraping sounds emanating from the brake assembly.

Possible Causes:

- Worn brake shoes or drums.

- Loose brake components.

- Foreign object lodged in the brake assembly.

Troubleshooting Steps:

- Inspect the brake shoes and drums: Check for wear or damage. Replace if necessary.

- Tighten loose components: Ensure all brake hardware, including springs, retainers, and mounting bolts, are securely fastened.

- Inspect for foreign objects: Carefully examine the brake assembly for any debris, stones, or other foreign objects that may be causing noise or interference.

Remote Software Solutions: The Future of Automotive Repair

“With the increasing complexity of modern vehicles, remote diagnostics and software solutions are becoming invaluable tools in automotive repair,” says John Miller, a senior automotive electrical engineer specializing in remote diagnostics.

He further explains, “By remotely accessing a vehicle’s onboard computer system, skilled technicians can identify problems, update software, and even perform calibrations, significantly reducing downtime and inconvenience for vehicle owners.”

Remote Diagnostics Interface

Remote Diagnostics Interface

Conclusion

The Warner Electric Brake EM-180-20 is a robust braking system. However, understanding its operation and common issues can help you diagnose and address problems effectively. Remember to prioritize safety by performing regular maintenance and addressing any brake issues promptly. If you encounter persistent problems or are unsure about performing any of the troubleshooting steps, consult a qualified trailer mechanic.