The Warner Electric brake EM 180 20FBB is a crucial component in many trailer braking systems. When it malfunctions, it can lead to safety hazards and costly repairs. This guide will provide you with expert advice on diagnosing, troubleshooting, and potentially fixing issues with your Warner Electric EM 180 20FBB brake, even through remote software solutions.

Understanding the Warner Electric Brake EM 180 20FBB

The EM 180 20FBB is an electrically activated brake commonly used on trailers. Its robust design and reliable performance make it a popular choice. However, like any mechanical and electrical component, it can experience issues. Understanding the common problems associated with this brake is the first step towards effective troubleshooting.

Common Issues with the Warner Electric EM 180 20FBB

Some common problems include: no power to the brake magnets, worn brake shoes, seized components due to corrosion, and issues with the breakaway cable system. Identifying the specific problem requires a systematic diagnostic approach.

Diagnosing Power Issues with the EM 180 20FBB

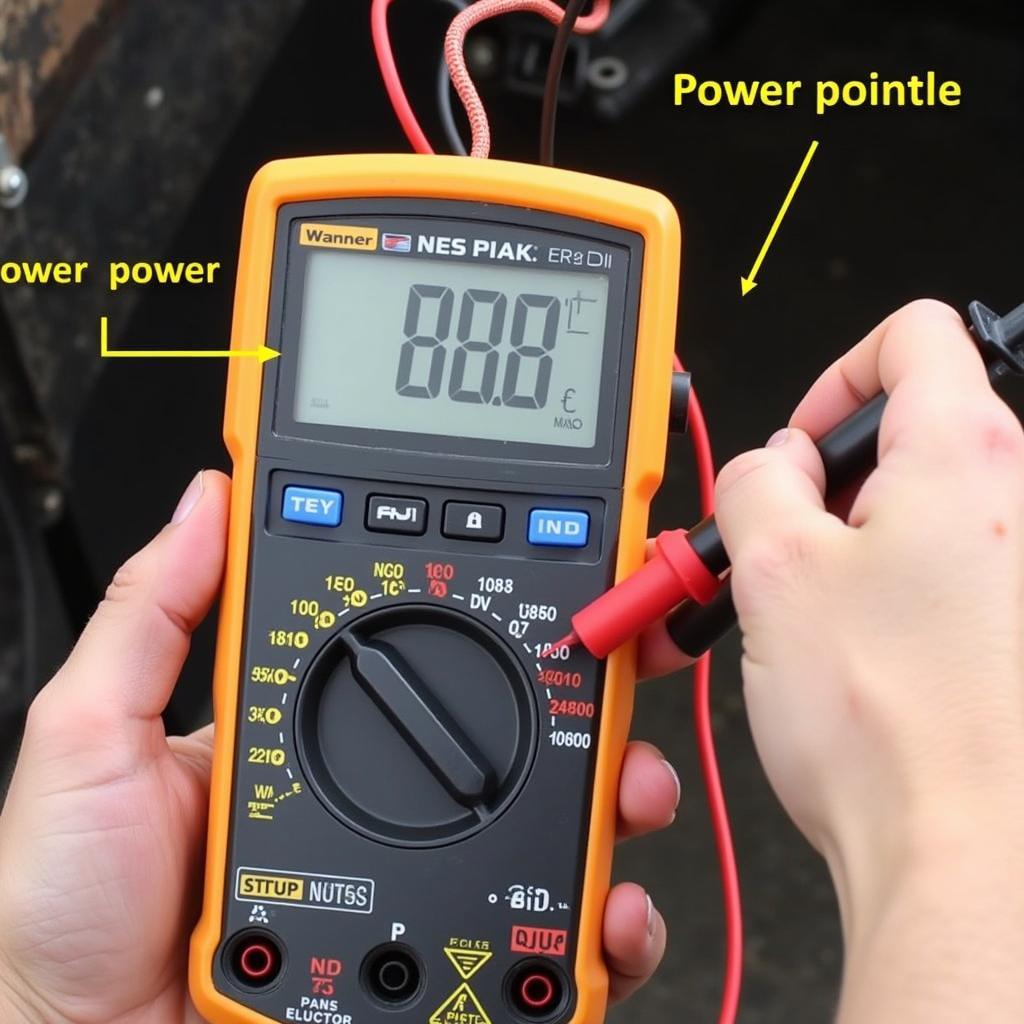

Begin by checking the 12-volt power supply to the brake magnets. Use a multimeter to verify voltage at the connector. If no power is present, trace the wiring back to the source, checking for breaks or loose connections.

Checking power supply to the Warner Electric brake EM 180 20FBB with a multimeter

Checking power supply to the Warner Electric brake EM 180 20FBB with a multimeter

Inspecting Brake Shoes and Mechanical Components

Physically inspect the brake shoes for wear and tear. Measure the thickness and compare it to the manufacturer’s specifications. Also, check for seized components, especially after exposure to harsh weather conditions. Corrosion can prevent the brake from engaging or disengaging properly.

Utilizing Remote Diagnostics and Software Solutions

Modern advancements in automotive technology allow for remote diagnostics and software updates. This can be particularly helpful in identifying complex issues with the EM 180 20FBB. Specialized software can pinpoint malfunctions and even provide solutions without physical intervention.

How Remote Programming Can Resolve EM 180 20FBB Issues

In some cases, software updates or recalibration can resolve issues related to the electronic control unit (ECU) that governs the brake system. This can often be performed remotely, saving time and money.

Preventing Future Problems with your Warner Electric Brake EM 180 20FBB

Regular maintenance is key to preventing future problems. This includes routine inspections, cleaning, and lubrication of moving parts. Protecting the brake system from the elements can also significantly extend its lifespan.

Conclusion

Properly maintaining and troubleshooting your Warner Electric brake EM 180 20FBB is crucial for safe and efficient trailer operation. By understanding the common issues, utilizing diagnostic techniques, and embracing remote software solutions, you can keep your braking system in optimal condition. Remember that regular maintenance is the best way to prevent future problems and ensure reliable performance.

FAQ

- What is the most common issue with the Warner Electric brake EM 180 20FBB? Power supply issues are often the culprit.

- Can I diagnose the EM 180 20FBB myself? Yes, basic diagnostics can be performed with a multimeter and visual inspection.

- What are the signs of worn brake shoes? Thin brake shoes, squeaking noises, and reduced braking performance are common signs.

- How can remote diagnostics help? Remote diagnostics can pinpoint complex electronic issues and even allow for software updates.

- How often should I inspect my trailer brakes? Regular inspections every six months or 12,000 miles are recommended.

- What is the role of the breakaway cable? The breakaway cable activates the brakes if the trailer becomes detached from the towing vehicle.

- Where can I find the manufacturer’s specifications for the EM 180 20FBB? The manufacturer’s website or owner’s manual will provide detailed specifications.