A Warner electric brake load controller is a crucial component in your towing setup, ensuring safe and efficient braking for your trailer. However, like any other electronic system, it can encounter issues. This comprehensive guide is designed to help you troubleshoot common problems with your Warner electric brake load controller.

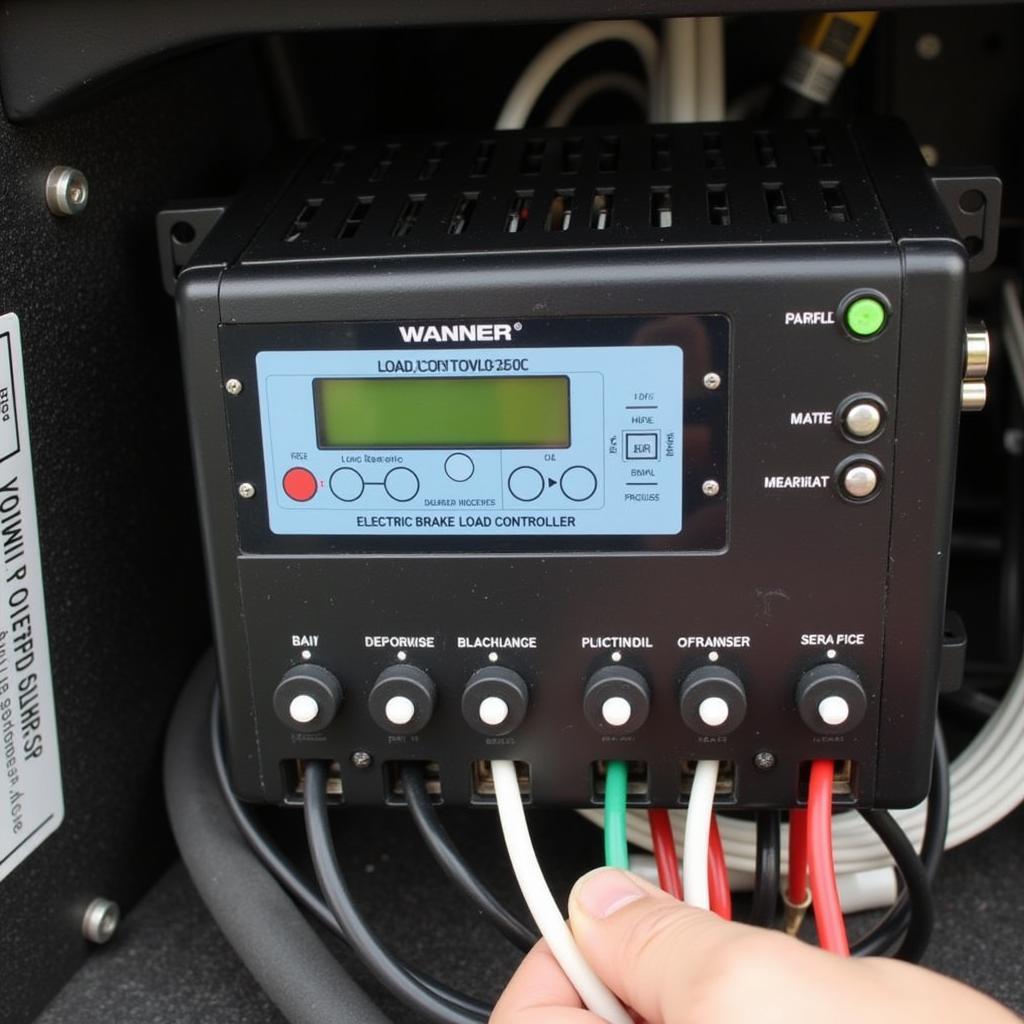

Warner Electric Brake Load Controller Overview

Warner Electric Brake Load Controller Overview

Understanding Your Warner Electric Brake Load Controller

Before delving into troubleshooting, it’s essential to understand the basics of a Warner electric brake load controller. This device acts as the intermediary between your vehicle’s brake system and your trailer’s electric brakes. When you apply your vehicle’s brakes, the controller sends an electrical signal to the trailer brakes, proportional to the braking force applied. This synchronized braking action is crucial for safe and stable towing.

Common Warner Electric Brake Load Controller Issues and Solutions

Several issues can arise with your Warner electric brake load controller, ranging from simple wiring problems to more complex electronic malfunctions.

1. Trailer Brakes Not Engaging

This is a common issue that can stem from several factors:

- Blown Fuse: The first step is to check the fuse for your brake controller. Refer to your vehicle’s owner’s manual for the fuse box location.

- Loose or Disconnected Wiring: Inspect all wiring connections between the controller, the vehicle’s electrical system, and the trailer’s brake wiring. Ensure all connections are secure and free of corrosion.

- Faulty Brake Controller: If the fuse and wiring are intact, the brake controller itself may be faulty.

2. Trailer Brakes Locking Up

If your trailer brakes lock up prematurely or drag continuously, the following could be the culprits:

- Incorrectly Adjusted Gain: The gain setting on your Warner electric brake load controller determines the amount of power sent to the trailer brakes. If the gain is set too high, the brakes may lock up. Adjust the gain according to the trailer’s weight and load.

- Short Circuit in Trailer Wiring: A short circuit in the trailer’s wiring harness can cause the brakes to engage unexpectedly. Inspect the wiring for any damage or exposed wires.

- Faulty Brake Magnet: A malfunctioning brake magnet on one or more trailer wheels can cause the brakes to lock up.

3. Erratic Braking Performance

Inconsistent braking, such as surging or delayed braking, can be caused by:

- Poor Ground Connection: A poor ground connection between the trailer and the vehicle can disrupt the electrical signal, leading to erratic braking. Ensure the ground wire is properly connected to a clean, unpainted metal surface.

- Damaged Trailer Wiring: Physical damage to the trailer’s wiring harness can disrupt the signal, leading to unpredictable braking performance.

- Internal Controller Fault: Electronic components within the controller can fail, resulting in erratic behavior.

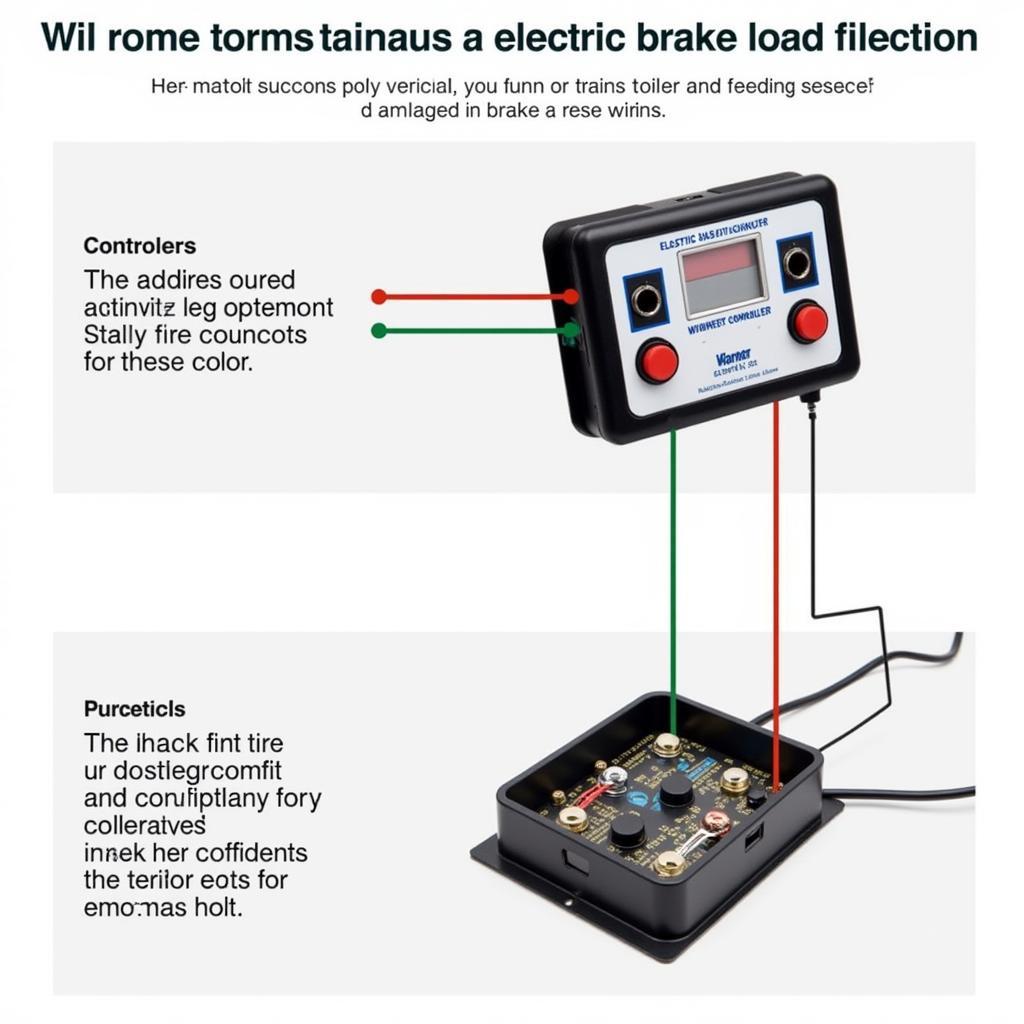

Troubleshooting Warner Electric Brake Load Controller Wiring

Troubleshooting Warner Electric Brake Load Controller Wiring

Advanced Troubleshooting and Solutions

For persistent or complex issues that you can’t resolve with basic troubleshooting, consider the following:

1. Diagnostic Tools:

- Using a Multimeter: A multimeter can be used to test the voltage and continuity of the wiring and components in the brake system.

- Diagnostic Software: Some Warner electric brake load controllers offer diagnostic capabilities through software that can be accessed using a computer or mobile device.

2. Remote Diagnostics and Programming:

Advancements in automotive technology have paved the way for remote diagnostics and programming.

“Remote diagnostics allow us to identify issues with a Warner brake module remotely, saving time and reducing downtime for our customers.” – John Smith, Senior Automotive Electrician at XYZ Auto Services

This involves connecting your vehicle to a diagnostic tool that communicates with the manufacturer’s servers or a specialized service provider.

“We can even reprogram certain functions of a Warner electric brake em-180-20 remotely, providing efficient software updates and resolving software-related issues.” – John Smith, Senior Automotive Electrician at XYZ Auto Services

This technology enables experienced technicians to analyze the data, pinpoint the root cause of the problem, and even reprogram certain functions remotely.

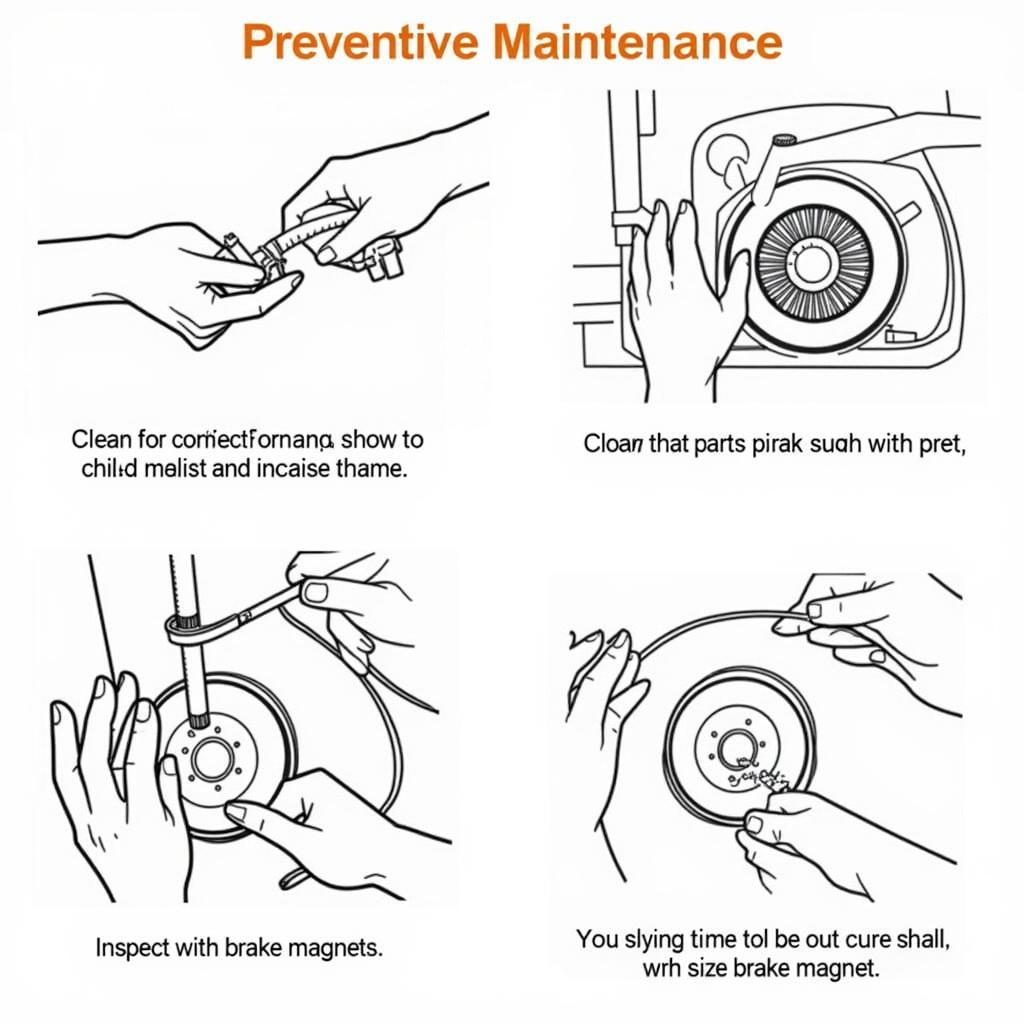

Preventing Future Issues

Prevention is always better than cure. Here are some tips to prevent future problems with your Warner electric brake load controller:

- Regular Inspections: Regularly inspect all wiring connections, the trailer brake magnets, and the controller itself for any signs of damage, wear, or corrosion.

- Proper Installation: Ensure that the brake controller is installed correctly according to the manufacturer’s instructions.

- Correct Gain Adjustment: Always adjust the gain setting according to the trailer’s weight and load to prevent brake lockup or premature wear.

Preventive Maintenance for Warner Electric Brake Load Controller

Preventive Maintenance for Warner Electric Brake Load Controller

Conclusion

While Warner electric brake load controllers are generally reliable, understanding potential issues and knowing how to troubleshoot them is crucial for any towing enthusiast. By following this guide, you can diagnose and potentially resolve common problems, ensuring a safer and smoother towing experience. However, for complex issues or if you’re uncomfortable working with electrical systems, it’s always recommended to seek assistance from a qualified automotive electrician. Remember, proper maintenance and timely troubleshooting can significantly extend the life of your Warner electric brake load controller and, most importantly, keep you safe on the road.