Warner electric brake magnets are crucial components in trailer braking systems, ensuring safe and controlled stops. A malfunctioning magnet can lead to braking issues, posing a safety risk. This comprehensive guide will equip you with the knowledge to diagnose and troubleshoot common problems with Warner electric brake magnets, helping you get back on the road safely and efficiently. Learn about common issues, diagnostic techniques, and solutions for your trailer’s braking system.

If you’re looking for replacement parts, check out our selection of warner electric trailer brake parts.

Understanding Warner Electric Brake Magnets

Warner electric brake magnets are electromagnets that activate the brakes on your trailer when you apply the brakes in your tow vehicle. They work in conjunction with a brake controller, which sends an electrical signal to the magnets, creating a magnetic field. This field pulls the magnet towards the brake drum, engaging the brakes. Understanding this basic principle is the first step in effective troubleshooting. These magnets are designed for durability and reliability, but like any mechanical component, they can experience wear and tear over time.

Common Problems with Warner Electric Brake Magnets

Several issues can arise with Warner electric brake magnets, ranging from simple wear and tear to more complex electrical problems. Some of the most common problems include:

- No Power to the Magnets: This can be caused by a faulty brake controller, a blown fuse, or damaged wiring.

- Weak or Uneven Braking: This could indicate a worn-out magnet, a low voltage issue, or an improperly adjusted brake controller.

- Overheating Magnets: Overheating can be a sign of a seized or sticking magnet, incorrect wiring, or excessive braking.

- Magnet Not Releasing: A magnet that fails to release can be caused by a mechanical issue within the magnet itself or a problem with the brake controller.

- Intermittent Braking Issues: This can be one of the most challenging problems to diagnose and can be caused by a variety of factors, including loose connections, corroded wires, or a faulty ground connection.

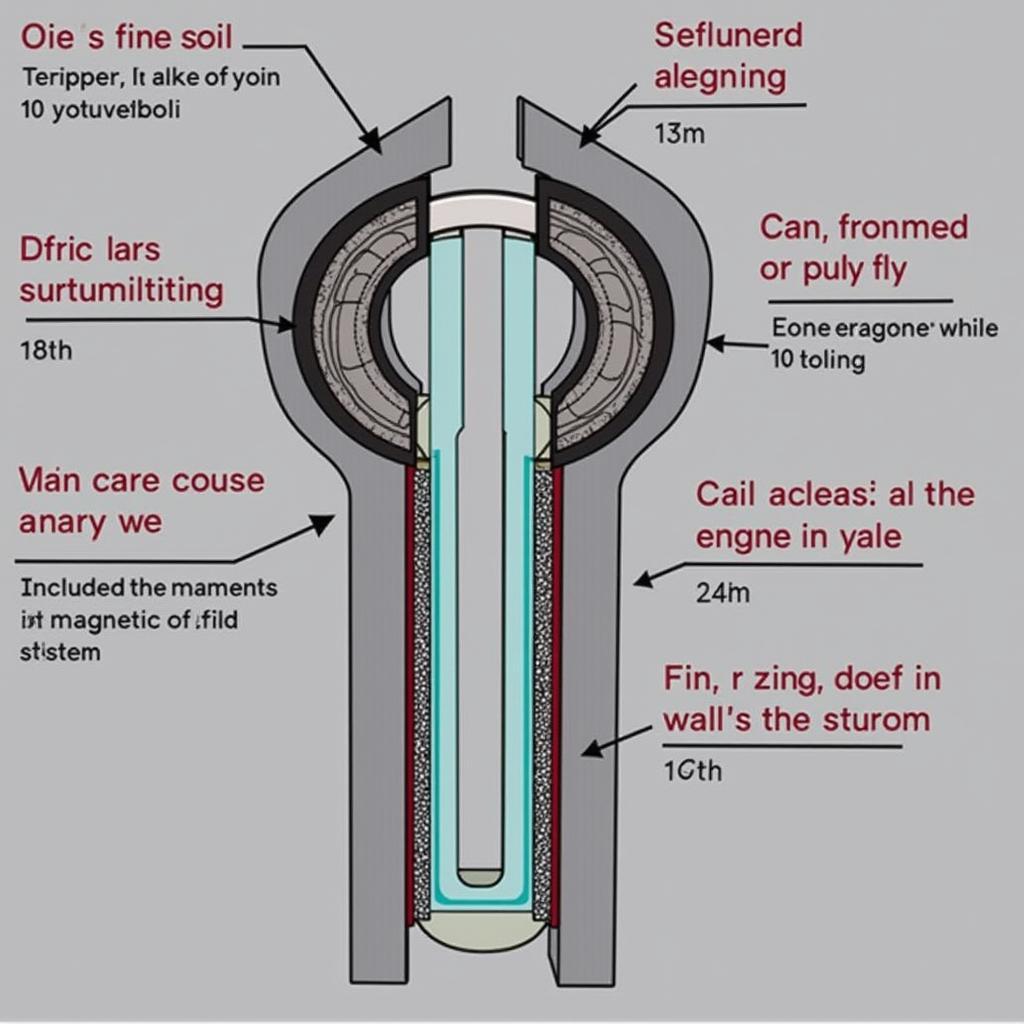

Warner Electric Brake Magnet Diagram

Warner Electric Brake Magnet Diagram

Diagnosing Warner Electric Brake Magnet Problems

Diagnosing the issue with your Warner electric brake magnets requires a systematic approach. Here’s a step-by-step guide to help you identify the root cause:

- Check the Brake Controller: Ensure the brake controller is properly installed and adjusted. Refer to the manufacturer’s instructions for specific guidance.

- Inspect the Wiring: Carefully examine the wiring harness for any signs of damage, corrosion, or loose connections. Pay particular attention to the ground connection, which is crucial for proper operation.

- Test for Power: Use a multimeter to check for voltage at the brake magnet connector. This will determine if the magnets are receiving power from the controller.

- Measure Magnet Resistance: Using a multimeter, measure the resistance of the brake magnets. Compare the readings to the manufacturer’s specifications to identify any faulty magnets.

- Inspect the Brake Drum and Shoes: Remove the brake drum and inspect the brake shoes for wear and tear. Check for any signs of overheating or damage to the magnet itself.

If you’re experiencing problems with your brake controller, you might want to consider a warner electric brake controller.

Testing Warner Electric Brake Magnet with Multimeter

Testing Warner Electric Brake Magnet with Multimeter

Solutions for Warner Electric Brake Magnet Problems

Once you have diagnosed the problem, you can implement the appropriate solution:

- Replace Faulty Magnets: If a magnet is found to be faulty, replace it with a new one.

- Repair or Replace Wiring: Damaged or corroded wiring should be repaired or replaced. Ensure all connections are secure and properly insulated.

- Adjust Brake Controller: If the brake controller is improperly adjusted, adjust it according to the manufacturer’s instructions.

- Clean and Lubricate Brake Components: Clean the brake drum and shoes, and lubricate the moving parts to ensure smooth operation.

John Smith, a certified automotive technician with over 20 years of experience, advises, “Regular inspection and maintenance of your trailer’s braking system, including the Warner electric brake magnets, can prevent many problems and ensure optimal performance.”

How to Prevent Future Problems

Regular maintenance is key to preventing future issues with your Warner electric brake magnets. Here are some preventative measures:

- Inspect Wiring Regularly: Check the wiring harness for any signs of damage or corrosion.

- Keep Brakes Adjusted: Ensure the brakes are properly adjusted to prevent overheating and premature wear of the magnets.

- Clean and Lubricate Brakes: Regularly clean and lubricate the brake components to prevent seizing and ensure smooth operation.

Adjusting Warner Electric Trailer Brakes

Adjusting Warner Electric Trailer Brakes

For those interested in electric brakes with Pulse Width Modulation, we also offer information on the power warner pk elctric brake with pwm.

Conclusion

Warner electric brake magnets are essential for safe and efficient trailer braking. By understanding how they work, recognizing common problems, and following the diagnostic and troubleshooting steps outlined in this guide, you can maintain your trailer’s braking system in optimal condition and ensure safe travels. Remember, regular maintenance is crucial for preventing future problems and extending the lifespan of your Warner electric brake magnets. Don’t hesitate to consult a qualified technician if you encounter any complex issues. By taking proactive steps, you can ensure the reliability and safety of your trailer’s braking system for years to come.

You might also find helpful information on warner electric trailer wheel brake parts.

Another helpful resource to check out is our guide on the warner brake controller 1300 80.