The Warner Electric Brake Manual is an essential resource for anyone who owns or operates a vehicle with electric brakes. This comprehensive guide provides detailed information on the installation, operation, and maintenance of your Warner electric brake system. However, even with a manual, troubleshooting brake issues can be a daunting task. This guide goes beyond the basics, providing you with expert insights into diagnosing and resolving common Warner electric brake problems.

Understanding how your electric brake system functions is the first step to effective troubleshooting. Unlike traditional hydraulic brake systems, Warner electric brakes utilize electronic components to activate the trailer brakes, offering superior control and stopping power.

Common Warner Electric Brake Problems and Solutions

Let’s delve into some common issues you might encounter with your Warner electric brake system, along with practical solutions:

1. No Trailer Brakes

Scenario: You hit the brakes, but your trailer doesn’t respond, posing a serious safety hazard.

Possible Causes:

- Blown Fuse: Start by checking the fuse associated with your brake controller. A blown fuse interrupts the electrical circuit, disabling the brakes.

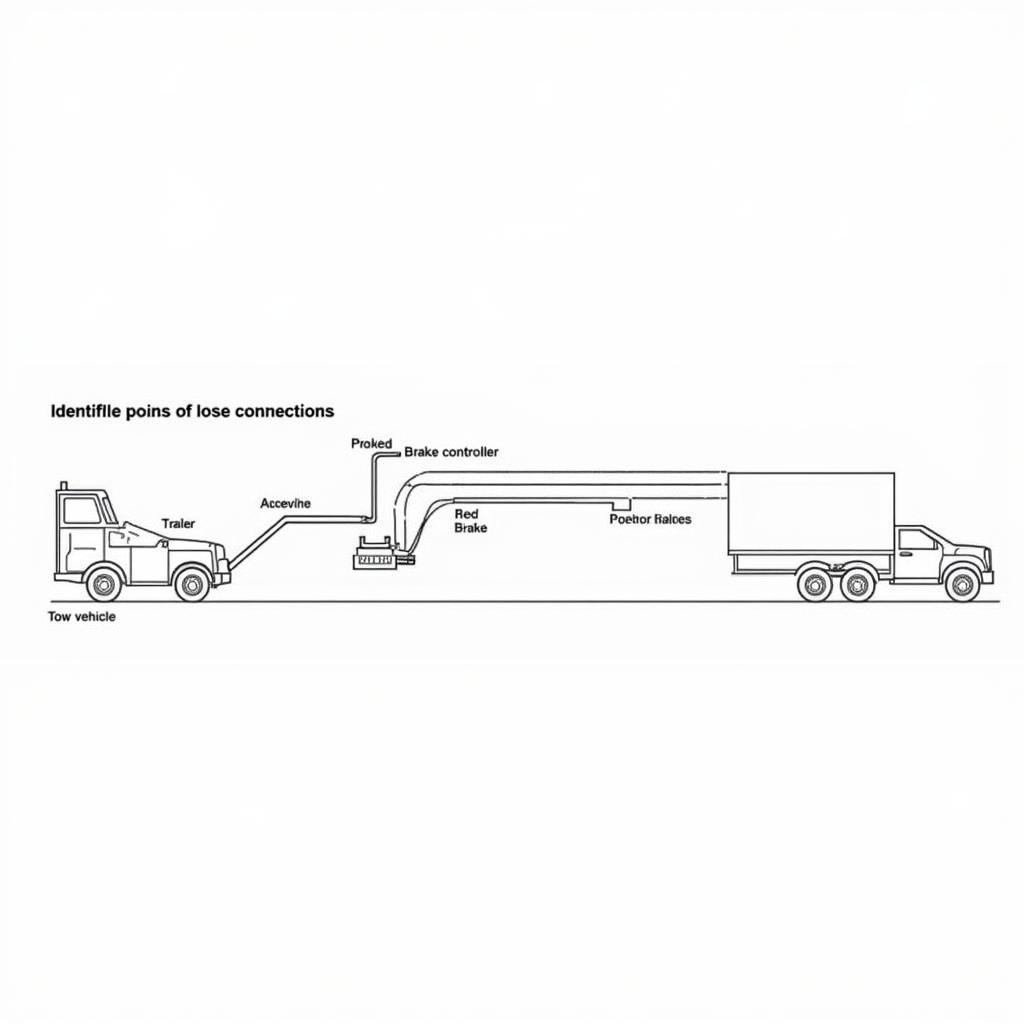

- Loose or Disconnected Wiring: Inspect all wiring connections between your vehicle and trailer, ensuring they are secure and free of corrosion.

- Faulty Brake Controller: A malfunctioning brake controller can fail to send the necessary signals to the trailer brakes.

- Worn Brake Shoes: Excessively worn brake shoes may require replacement to restore proper braking function.

Warner Electric Brake Wiring Diagram

Warner Electric Brake Wiring Diagram

Troubleshooting Tips:

- Begin by checking the simplest things, like the fuse and wiring connections.

- If you suspect a brake controller issue, consider temporarily connecting a different, known-working controller to rule out a controller malfunction.

- For brake shoe inspection, consult your Warner Electric Brake Service Manual for the proper procedures and safety precautions.

Quote: “Always prioritize safety when working on your braking system. If you’re unsure about any step, consult a qualified mechanic.” – John Miller, Certified Automotive Electrician

2. Trailer Brakes Lock Up

Scenario: Your trailer brakes engage even without applying the brake pedal, causing the wheels to lock up.

Possible Causes:

- Short Circuit: A short circuit in the wiring can send continuous power to the brakes, leading to lockup.

- Faulty Brake Controller: A malfunctioning brake controller can send incorrect signals to the trailer brakes, causing them to engage unintentionally.

- Sticking Brake Magnet: The brake magnet, responsible for applying the brakes, may get stuck in the engaged position.

Troubleshooting Tips:

- Carefully inspect the wiring harness for any signs of damage, pinching, or exposed wires that could be causing a short circuit.

- If you suspect a brake controller issue, try temporarily replacing it with a known-working one to isolate the problem.

- To address a potentially sticking brake magnet, consult your Warner Electric Brake Service Manual for disassembly and lubrication instructions.

3. Inconsistent Braking Performance

Scenario: You experience inconsistent braking response from your trailer; sometimes it brakes effectively, other times it feels weak or delayed.

Possible Causes:

- Poor Electrical Connection: Loose or corroded connections can interrupt the flow of electricity, leading to inconsistent brake engagement.

- Worn Brake Drums or Rotors: Worn brake components can reduce friction and cause inconsistent braking performance.

- Incorrectly Adjusted Brakes: Improper brake adjustment can result in uneven brake shoe contact, leading to an inconsistent feel.

Troubleshooting Tips:

- Meticulously check all wiring connections, cleaning any corrosion and ensuring a tight fit.

- If your trailer has drum brakes, inspect the drums for excessive wear or scoring. For trailers with disc brakes, check the rotors for similar issues.

- Consult your Warner Electric Brake Service Manual for detailed instructions on how to properly adjust your trailer’s brakes.

Quote: “Regular maintenance, including inspecting your brake system, can prevent many common issues and ensure optimal performance.” – Sarah Thompson, Automotive Engineer

Warner Electric Brake Controller Troubleshooting

Your Warner electric brake controller plays a pivotal role in the overall functionality of your electric brake system. Here’s a closer look at troubleshooting controller-specific issues:

1. No Display on the Controller

Scenario: Your brake controller’s display screen remains blank, leaving you with no indication of its status or settings.

Possible Causes:

- Power Issue: The controller may not be receiving power due to a blown fuse, loose wiring, or a problem with the vehicle’s electrical system.

- Faulty Controller: A malfunctioning controller may experience internal electrical problems that prevent the display from illuminating.

Troubleshooting Tips:

- Check the fuse related to your brake controller’s power supply. If the fuse is blown, replace it with a fuse of the correct amperage.

- Trace the wiring harness from the controller to the vehicle’s electrical system, ensuring all connections are secure and free of corrosion.

- If you suspect a faulty controller, try temporarily connecting a different, known-working controller to rule out a controller issue.

2. Error Codes on the Controller

Scenario: Your brake controller displays error codes, signaling a potential problem within the system.

Possible Causes:

- Short Circuit or Open Circuit: Error codes often indicate a problem with the electrical circuit, such as a short circuit or an open circuit.

- Faulty Trailer Wiring: Issues with the trailer’s wiring harness, such as damaged wires or loose connections, can trigger error codes.

- Controller Malfunction: In some cases, a malfunctioning brake controller may display error codes even if there are no underlying issues with the wiring or trailer brakes.

Troubleshooting Tips:

- Refer to your Warner Electric Brake Manual for a list of error codes and their corresponding meanings.

- Carefully inspect the wiring harness for any signs of damage, pinching, or exposed wires.

- Using a multimeter, you can test for continuity in the wiring harness to identify any open circuits or short circuits.

Warner Electric Brake Manual: Beyond the Basics

While your Warner Electric Brake Manual is a valuable resource, it may not cover every troubleshooting scenario. This guide has provided you with additional insights and practical solutions for common electric brake problems.

Remember, a properly functioning brake system is paramount for your safety and the safety of others on the road. Regular maintenance, coupled with a solid understanding of your Warner electric brake system, can help you avoid potential issues and ensure reliable braking performance.

For specialized repairs or if you encounter persistent issues, don’t hesitate to seek professional assistance from a qualified automotive electrician.

FAQs

1. Where can I find a Warner Electric Brake Service Manual?

You can often find service manuals on the Warner Electric website or through reputable online retailers.

2. How often should I inspect my electric brake system?

It’s recommended to inspect your electric brake system at least twice a year, or more frequently if you tow regularly.

3. Can I install a Warner electric brake controller myself?

While it’s possible, installing a brake controller requires some electrical knowledge. If you’re not comfortable working with automotive electrical systems, it’s best to consult a professional.

4. What type of maintenance does my Warner electric brake system require?

Regular maintenance includes inspecting and cleaning all wiring connections, checking the brake shoes or pads for wear, and lubricating moving parts as needed.

5. How do I know if my Warner electric brake controller is compatible with my trailer’s brakes?

Check the specifications of your brake controller and trailer brakes to ensure they are compatible in terms of voltage and amperage requirements.