Warner electric clutch brake control systems are crucial for precise motion control in various industrial and automotive applications. Understanding how to diagnose, program, and even remotely troubleshoot these systems can save valuable time and resources. This comprehensive guide dives into the intricacies of Warner electric clutch brake control, empowering you with the knowledge to tackle common issues and optimize performance. Check out more information on the warner electric clutch brake control cbc 150 1.

Understanding the Core Components of Warner Electric Clutch Brake Control

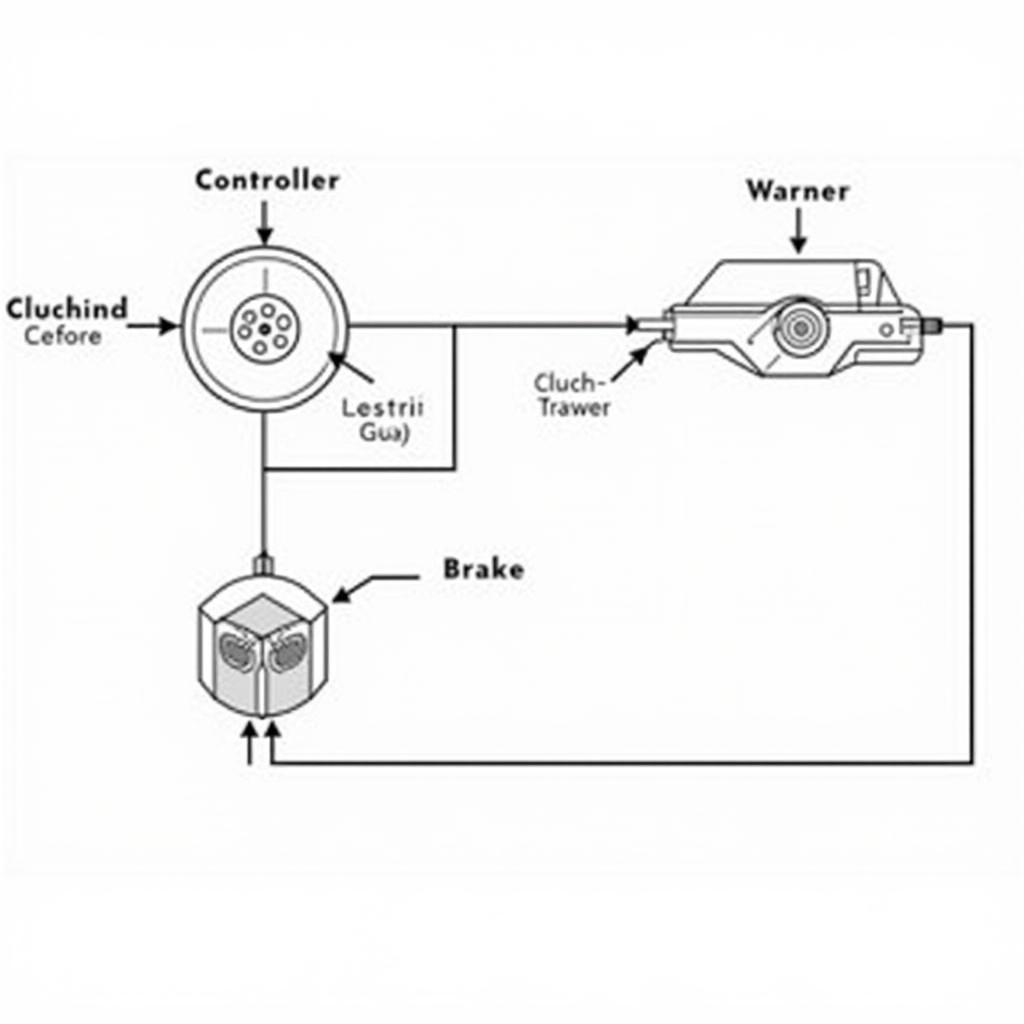

A Warner electric clutch brake control system typically consists of a controller, a clutch, and a brake. The controller manages the engagement and disengagement of the clutch and brake based on input signals, allowing for precise control of motion and positioning. Various types of controllers exist, each offering specific functionalities and features.

Warner Electric Clutch Brake Control System Components

Warner Electric Clutch Brake Control System Components

Clutches and brakes are available in different designs, including electromagnetic, hydraulic, and pneumatic. The choice depends on the specific application requirements, such as torque, speed, and environmental conditions. Understanding these core components is the first step to effectively diagnosing and resolving issues.

Common Issues with Warner Electric Clutch Brake Control Systems

Several factors can contribute to problems with Warner electric clutch brake control systems. Wear and tear on the clutch or brake linings, electrical malfunctions, and improper controller settings are some of the common culprits. Troubleshooting these issues requires a systematic approach.

Diagnosing Problems with Your Warner Electric Clutch Brake Control

Begin by visually inspecting the system for any obvious signs of damage or wear. Next, check the electrical connections for loose wires or corrosion. Utilize diagnostic tools to monitor the system’s performance and identify any irregularities.

Troubleshooting Tips for Effective Repair

Once you’ve identified the problem, the next step is to implement the appropriate solution. This could involve replacing worn parts, repairing electrical connections, or adjusting the controller settings. Sometimes, remote diagnostics and programming can be a viable solution, saving time and travel costs. Learn more about this specific model: warner electric clutch brake control cbc 150 1 manual.

“Regular maintenance is key to preventing issues with your Warner electric clutch brake control,” says John Smith, Senior Automotive Engineer at Acme Industries. “This includes inspecting and cleaning the system, lubricating moving parts, and checking for any signs of wear or damage.”

Remote Programming and Diagnostics for Warner Electric Clutch Brake Control

Remote diagnostics and programming offer a convenient and efficient way to address certain issues without the need for on-site intervention. Using specialized software and communication interfaces, technicians can access the system remotely, diagnose problems, and even upload new software or adjust settings.

Benefits of Remote Solutions for Warner Electric Systems

Remote solutions offer several advantages, including reduced downtime, lower travel costs, and faster response times. This technology allows for quick identification and resolution of problems, minimizing disruptions to operations.

“Remote diagnostics have revolutionized the way we troubleshoot Warner electric clutch brake control systems,” comments Jane Doe, Lead Technician at Global Automation Solutions. “The ability to quickly identify and resolve issues remotely saves us significant time and resources.” For more information about pricing, visit our warner electric brake clutch price list.

Ensuring Optimal Performance of Your Warner Electric Clutch Brake Control

Proper maintenance and timely repairs are essential for maximizing the lifespan and performance of your Warner electric clutch brake control system. Regularly inspect the system for any signs of wear or damage, lubricate moving parts, and keep the system clean. For specific information regarding the company’s headquarters, see warner electric brake and clutch co hq. Explore other related clutch and brake systems at kaman warner clutch brake.

In conclusion, understanding the intricacies of Warner electric clutch brake control allows you to effectively diagnose, troubleshoot, and maintain these critical systems. By leveraging remote programming and diagnostics and adhering to a regular maintenance schedule, you can optimize performance, minimize downtime, and extend the life of your equipment.