The Warner Electric FB-650 90V brake is a vital component in many industrial and automotive applications. When this brake malfunctions, it can lead to downtime and safety concerns. This comprehensive guide will walk you through diagnosing, troubleshooting, and resolving common issues with your Warner Electric FB-650 90V brake, empowering you to get your equipment back up and running smoothly.

Understanding the Warner Electric FB-650 90V Brake

The FB-650 is a powerful, electrically released brake designed for demanding applications. Understanding its basic operation is key to effective troubleshooting. The brake engages when power is removed, using a spring mechanism to clamp down on a brake drum. Applying 90V DC releases the brake, allowing the drum to rotate freely. Common issues can stem from electrical problems, mechanical wear, or incorrect installation.

Common Problems and Solutions for the FB-650 90V Brake

Several issues can arise with the Warner Electric FB-650 90V brake. Here are some of the most frequent problems and their solutions:

- Brake Fails to Release: This is often due to a lack of voltage to the brake solenoid. Check the power supply, wiring, and connections. A faulty solenoid may also be the culprit.

- Brake Fails to Engage: A worn or broken spring, or excessive air gap between the brake shoes and the drum, can prevent engagement. Inspect the spring and adjust the air gap as needed.

- Slow Release or Engagement: This can be caused by binding in the brake mechanism, low voltage, or worn components. Lubricate moving parts, check the voltage, and replace worn parts.

- Overheating: Excessive heat can indicate a dragging brake, incorrect voltage, or excessive cycling. Ensure the brake releases fully, verify the correct voltage, and optimize the application to reduce brake cycles.

- Noise or Vibration: This often points to worn brake linings, a loose mounting, or a problem with the drum. Inspect and replace worn linings, tighten all mounting hardware, and check the drum for damage.

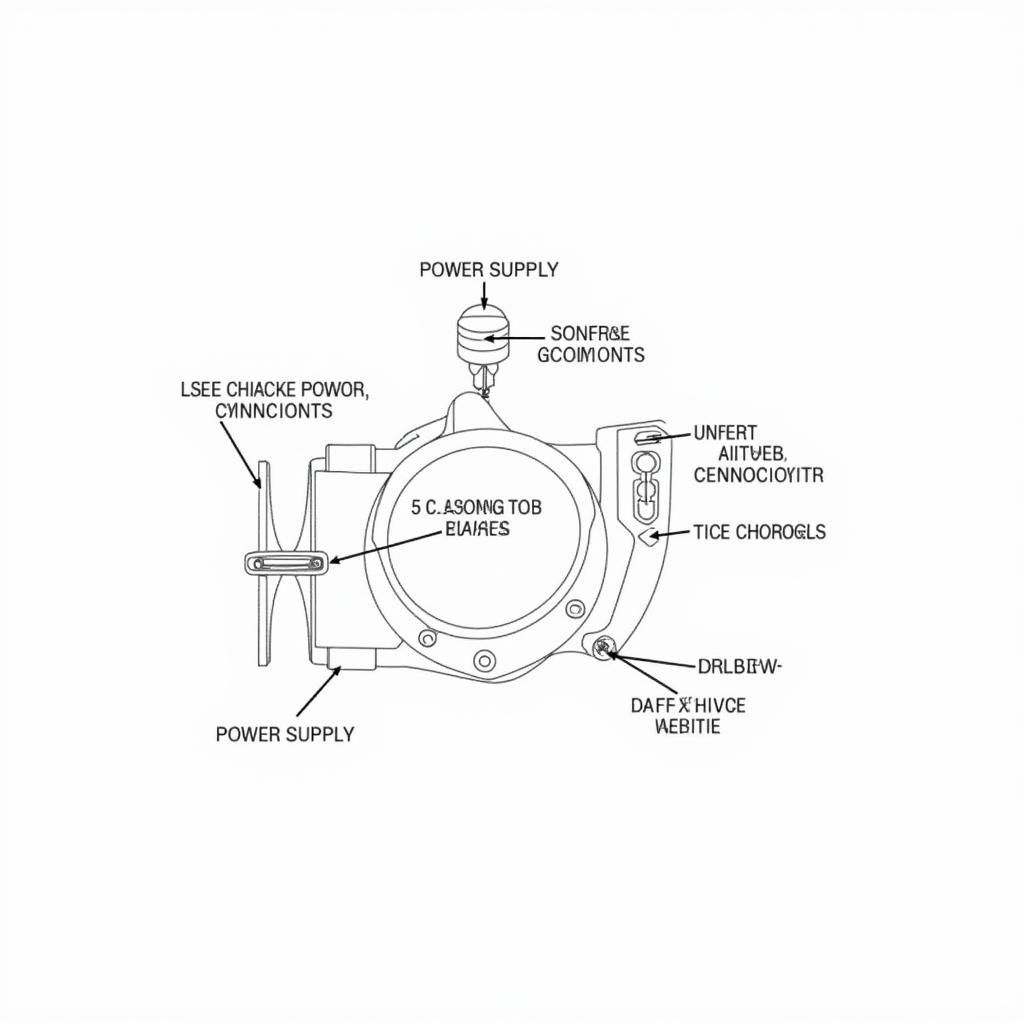

Warner Electric FB-650 90V Brake Wiring Diagram

Warner Electric FB-650 90V Brake Wiring Diagram

Diagnosing Electrical Problems with the FB-650

Electrical issues are a common cause of FB-650 malfunctions. Use a multimeter to check for voltage at the brake solenoid terminals. If voltage is present, the solenoid may be faulty. If no voltage is present, trace the wiring back to the power supply, checking for breaks or loose connections.

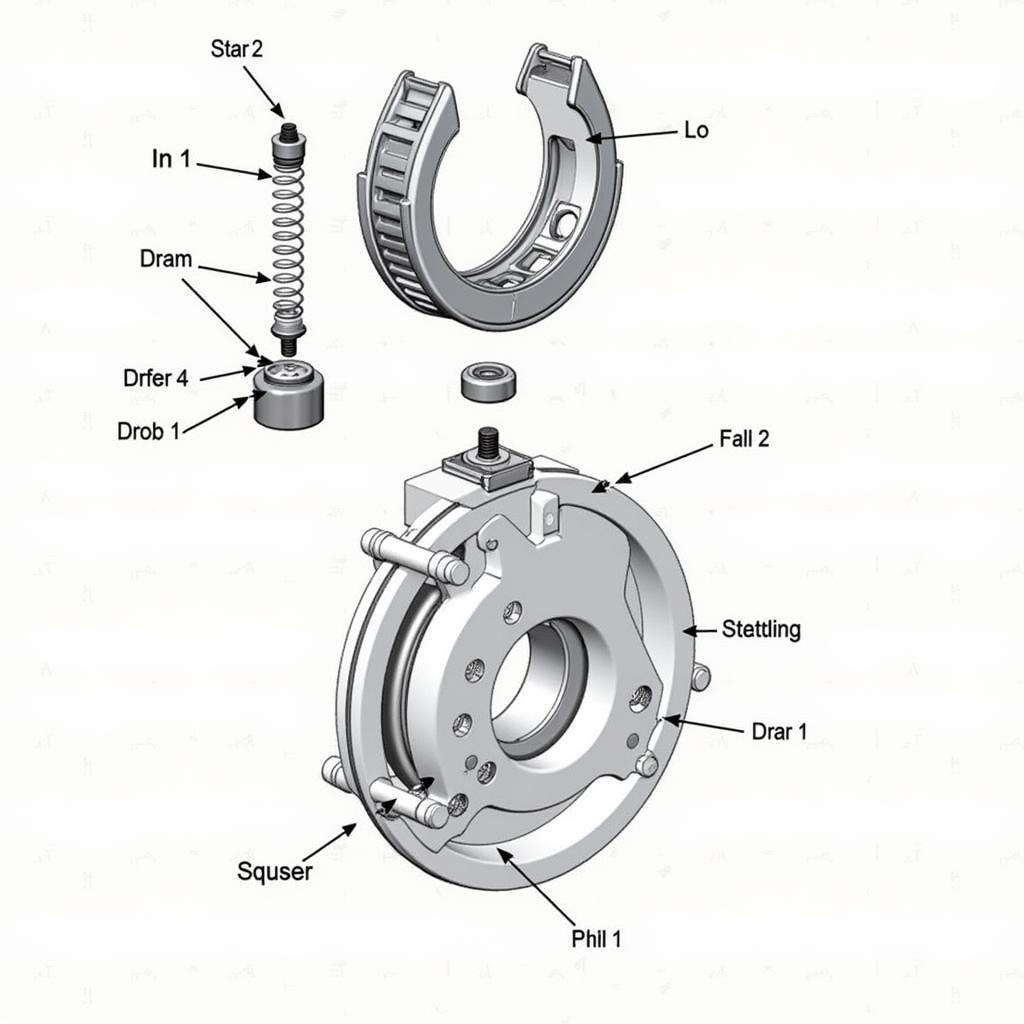

Mechanical Inspection and Maintenance

Regular mechanical inspection is crucial for preventing problems. Check the brake linings for wear, inspect the spring for damage, and ensure all moving parts are properly lubricated. Adjust the air gap between the brake shoes and drum according to the manufacturer’s specifications.

Warner Electric FB-650 90V Brake Mechanical Components

Warner Electric FB-650 90V Brake Mechanical Components

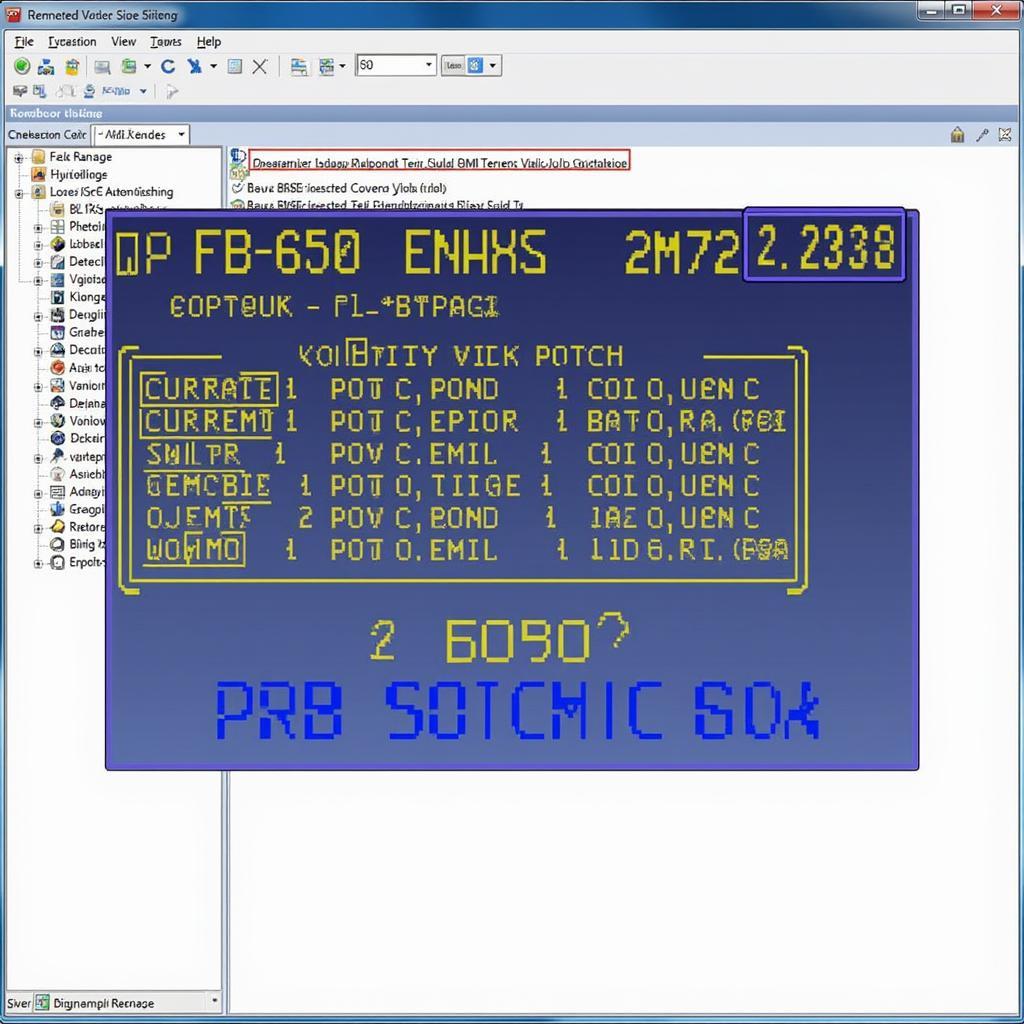

Remote Diagnostics and Software Solutions for the FB-650

In some cases, remote diagnostics and software solutions can be utilized to troubleshoot the FB-650. This allows for real-time data analysis and identification of potential issues without physical access to the brake.

“Remote diagnostics have revolutionized how we troubleshoot brakes like the FB-650,” says John Smith, Senior Electrical Engineer at Automotive Solutions Inc. “By analyzing data remotely, we can often pinpoint the problem quickly and efficiently, minimizing downtime.”

Remote Diagnostics Software Interface for FB-650 Brake

Remote Diagnostics Software Interface for FB-650 Brake

Preventing Future Problems

Regular maintenance and proper installation are key to preventing future issues with your Warner Electric FB-650 90V brake. Follow the manufacturer’s recommendations for lubrication and inspection intervals. Ensure the brake is correctly sized for the application and that the voltage supply is stable and within specifications.

“Proper preventative maintenance is the best way to avoid costly downtime,” adds Maria Garcia, Lead Technician at Industrial Brake Systems. “Regular inspections and timely replacements of worn parts will significantly extend the life of your FB-650 brake.”

Conclusion

Troubleshooting your Warner Electric FB-650 90V brake can seem daunting, but by following these guidelines, you can effectively diagnose and resolve common problems. Remember to always prioritize safety and consult the manufacturer’s documentation for specific instructions. With proper care and maintenance, your FB-650 brake will provide reliable performance for years to come.