Warner electric magnetic brakes are a crucial component in many industrial and automotive applications, providing reliable stopping power and control. While these brakes are generally known for their durability and performance, like any electromechanical system, they can occasionally experience issues.

This guide delves into the common problems associated with Warner electric magnetic brakes, offering troubleshooting tips and solutions to get your systems back up and running smoothly.

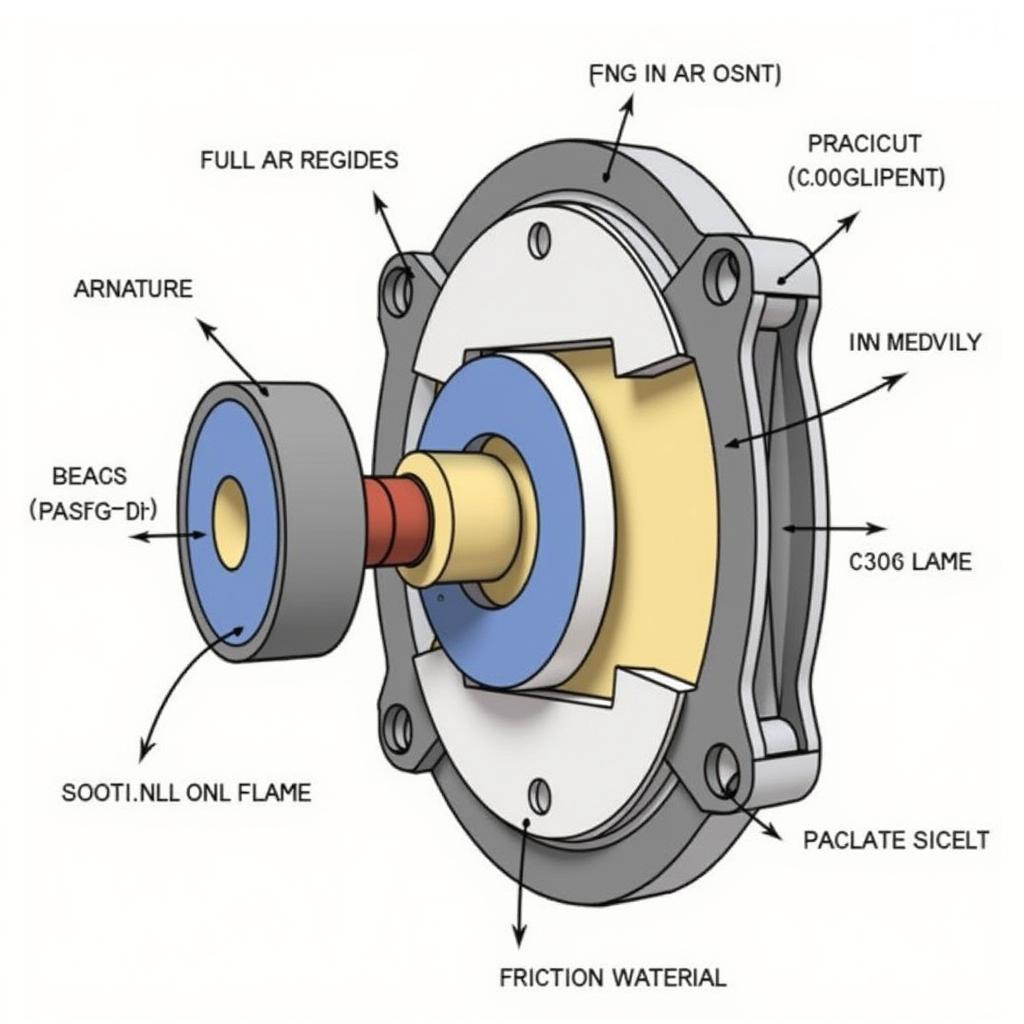

Understanding Warner Electric Magnetic Brakes

Before we dive into troubleshooting, it’s helpful to have a basic understanding of how these brakes work. Unlike traditional friction brakes, Warner electric magnetic brakes use electromagnetic force to stop or hold a load.

Warner Electric Magnetic Brake Components

Warner Electric Magnetic Brake Components

At the heart of the system is an electromagnet that generates a magnetic field when energized. This field attracts an armature, which is connected to the brake hub. The force of the attraction creates friction between the armature and the brake, generating the stopping power.

Common Warner Electric Magnetic Brake Problems and Solutions

Let’s explore some of the most common problems you might encounter with Warner electric magnetic brakes:

1. Brake Fails to Engage

Possible Causes:

- Loss of Power or Faulty Wiring: One of the most common reasons a brake fails to engage is a lack of power to the electromagnet. This could be due to a blown fuse, a broken wire, a disconnected connector, or a faulty switch.

- Worn Brake Components: Over time, the friction surfaces of the brake can wear down, reducing their effectiveness. If the armature or brake lining is excessively worn, the brake may not engage properly.

- Air Gap Adjustment: Warner electric magnetic brakes typically have an air gap specification that needs to be maintained for optimal performance. If the air gap is too large, the magnetic field may not be strong enough to engage the brake fully.

- Coil Failure: A burned-out or damaged coil in the electromagnet will prevent it from generating the magnetic field needed to engage the brake.

Troubleshooting Tips:

- Check the Power Supply: Use a multimeter to verify that the correct voltage is reaching the brake coil. Inspect all wiring, connectors, and fuses for any signs of damage or loose connections.

- Inspect Brake Components: Visually examine the armature and brake lining for signs of excessive wear or damage. If the components are worn beyond their service limit, replace them.

- Verify Air Gap: Consult the manufacturer’s specifications for the correct air gap measurement. Use a feeler gauge to measure the gap and adjust it as needed.

- Test the Coil: Use a multimeter to check the coil’s resistance. If the resistance is out of spec or if there’s no continuity, the coil may be faulty and needs replacement.

2. Brake Drags or Fails to Release

Possible Causes:

- Residual Magnetism: Sometimes, a small amount of magnetism can remain in the electromagnet even after the power is disconnected. This residual magnetism can cause the brake to drag or fail to release fully.

- Mechanical Binding: There might be physical obstructions or binding in the brake mechanism preventing the armature from releasing smoothly.

- Adjustment Issues: Improper adjustment of the release springs or other mechanical components can lead to brake drag.

Troubleshooting Tips:

- Check for Residual Magnetism: If you suspect residual magnetism, try cycling the brake power on and off a few times. This can help dissipate any remaining magnetic field.

- Inspect for Mechanical Issues: Carefully examine the brake mechanism for any signs of binding, debris, or misalignment. Clean and lubricate the moving parts as needed.

- Adjust Release Springs: Consult the manufacturer’s instructions for proper adjustment of the release springs. Ensure the springs have sufficient tension to overcome any residual magnetism and fully release the brake.

3. Overheating

Possible Causes:

- Excessive Slipping: If the brake is slipping excessively during operation, it can generate a significant amount of heat, potentially damaging the brake components.

- Incorrect Voltage: Supplying an incorrect voltage to the brake coil can cause it to overheat.

- Inadequate Cooling: In some applications, particularly those with frequent braking cycles, inadequate cooling can lead to overheating.

Troubleshooting Tips:

- Assess Brake Load: Ensure the brake is being used within its specified load capacity. An overloaded brake will slip more, leading to excessive heat.

- Verify Voltage Supply: Double-check that the voltage supplied to the brake coil matches the manufacturer’s specifications.

- Improve Cooling: If overheating is a recurring issue, consider implementing additional cooling measures, such as using a fan or heat sink.

Technician Troubleshooting a Warner Electric Magnetic Brake

Technician Troubleshooting a Warner Electric Magnetic Brake

Tips for Maintaining Warner Electric Magnetic Brakes

Regular maintenance can significantly extend the life of your Warner electric magnetic brakes and prevent many common problems:

- Visual Inspections: Regularly inspect the brakes for any visible signs of wear, damage, or loose components.

- Lubrication: Keep all moving parts properly lubricated with the recommended lubricant to reduce friction and wear.

- Air Gap Adjustments: Periodically check and adjust the air gap according to the manufacturer’s specifications.

- Cleanliness: Keep the brake assembly clean and free from debris, dirt, and contaminants that can affect performance.

- Professional Service: For complex issues or if you’re unsure about any aspect of maintenance, consult a qualified technician specializing in Warner electric magnetic brakes.

Remote Diagnostics and Software Solutions

In today’s technologically advanced world, remote diagnostics and software solutions are playing an increasingly important role in troubleshooting and maintaining automotive systems, including Warner electric magnetic brakes.

[warner electric magnetic particle brake](https://cardiagtech.com/warner electric magnetic particle brake/) often incorporate sensors and electronic control units (ECUs) that can provide valuable data about the brake’s performance.

Skilled technicians can leverage specialized diagnostic software to connect to the vehicle’s onboard computer system remotely, accessing real-time data from the brake’s sensors. This data can reveal valuable insights into the brake’s operation, helping to pinpoint the root cause of problems quickly and efficiently.

Conclusion

Warner electric magnetic brakes are robust and dependable braking solutions. However, understanding potential issues and following these troubleshooting tips can help you keep your systems operating at peak performance. Remember, regular maintenance and timely repairs are crucial for maximizing the lifespan of your Warner electric magnetic brakes. If you encounter complex problems or need expert assistance, don’t hesitate to contact a qualified technician specializing in warner electric brake clutch china.