Warner Electric trailer brakes are a vital safety feature for any towing setup, ensuring reliable and controlled braking for your trailer. However, like any mechanical system, they can encounter issues over time. This comprehensive guide delves into common problems with Warner Electric trailer brakes, empowering you with the knowledge to diagnose and potentially resolve them.

Understanding Warner Electric Trailer Brakes

Before diving into troubleshooting, it’s crucial to understand the basics of Warner Electric trailer brakes. Unlike hydraulic brakes that use brake fluid, electric trailer brakes utilize an electronic controller in your vehicle to apply braking force to the trailer. This system offers several advantages, including smoother braking, improved control, and easier installation compared to surge brake systems.

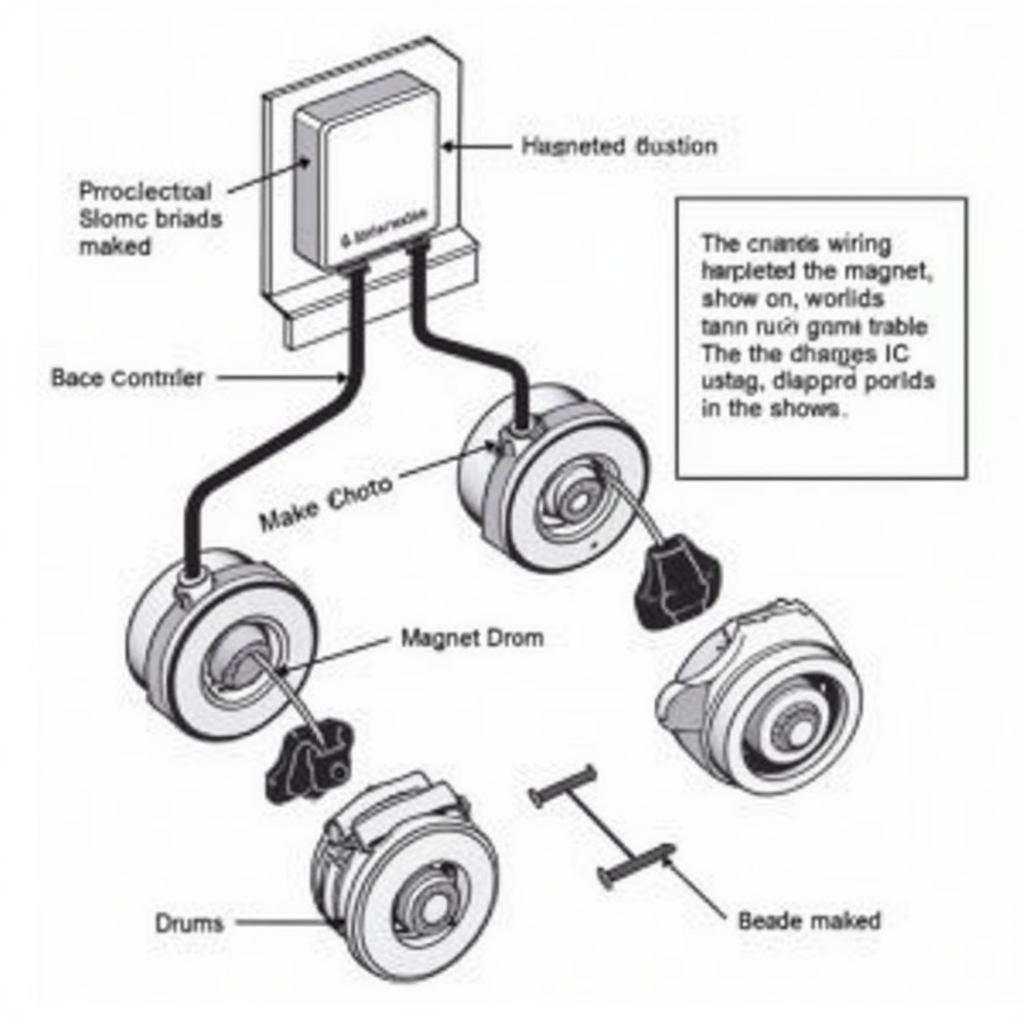

Warner Electric Trailer Brake System Components

Warner Electric Trailer Brake System Components

Common Warner Electric Trailer Brake Problems

While Warner Electric trailer brakes are generally reliable, certain issues can arise, often stemming from improper installation, wear and tear, or electrical problems. Here are some common problems you might encounter:

1. No Trailer Brakes

One of the most alarming issues is a complete lack of trailer brakes. Several factors can contribute to this problem:

- Faulty Brake Controller: The brake controller acts as the brain of the system. A malfunctioning controller won’t send the necessary signals to activate the trailer brakes.

- Wiring Issues: Damaged, corroded, or loose wiring between the vehicle and trailer can disrupt the electrical connection, preventing brake activation.

- Blown Fuses: Check both the vehicle and trailer fuse boxes for any blown fuses related to the trailer brakes.

- Bad Ground Connection: A poor ground connection can prevent the brakes from receiving sufficient power to operate.

2. Trailer Brakes Lock Up

On the other hand, trailer brakes locking up during operation can be equally dangerous. Potential causes include:

- Brake Controller Maladjustment: A controller set with excessive gain can apply too much braking power, leading to lockup.

- Short Circuit: A short circuit in the wiring can cause the brakes to engage unintentionally.

- Stuck Brake Caliper: A seized or stuck brake caliper on the trailer can prevent the brakes from releasing properly.

3. Intermittent Trailer Braking

Experiencing intermittent braking, where the brakes work erratically or cut in and out, can be particularly frustrating. Common culprits are:

- Loose Connections: Loose wiring connections can cause intermittent signal disruptions.

- Faulty Breakaway Switch: The breakaway switch activates the trailer brakes if it becomes detached from the towing vehicle. A malfunctioning switch can lead to intermittent braking.

- Damaged Brake Magnets: Worn or damaged brake magnets within the trailer brake drums may not create a consistent magnetic field, resulting in uneven braking.

Diagnosing Warner Electric Trailer Brake Issues

Accurately diagnosing the root cause of a trailer brake problem is paramount for effective repair.

Here’s a step-by-step approach:

- Check the Basics: Begin by inspecting the brake controller for proper connection and settings. Ensure it’s receiving power and the gain is adjusted appropriately.

- Inspect the Wiring: Thoroughly examine all wiring harnesses, connectors, and grounds for any signs of damage, corrosion, or looseness.

- Test the Voltage: Use a multimeter to test for voltage at various points in the system, including the brake controller output, trailer connector, and brake magnets.

- Inspect the Brakes: Physically inspect the trailer brake drums, shoes, and magnets for wear, damage, or any signs of overheating.

“When diagnosing trailer brake problems, a systematic approach is crucial. Start with the basics like checking connections and gradually move towards more complex components.” – John Miller, Senior Automotive Electrician at Mobile Auto Solutions.

[old warner trailer brakes]

Maintaining Your Warner Electric Trailer Brakes

Regular maintenance can significantly extend the life of your trailer brakes and prevent costly repairs.

Follow these essential tips:

- Inspect Regularly: Conduct visual inspections of the wiring, connectors, and brakes before each trip.

- Keep it Clean: Regularly clean the trailer brake drums and components to remove dirt, debris, and road salt that can accelerate wear.

- Lubricate Moving Parts: Apply a high-temperature lubricant to the moving parts of the brake system, such as the adjuster mechanisms and pivot points.

- Adjust as Needed: Periodically adjust the trailer brakes to ensure optimal performance and even wear on the brake shoes.

[warner electric brake load controller]

When to Seek Professional Help

While this guide provides insights into common Warner Electric trailer brake issues, certain situations warrant professional assistance:

- Complex Electrical Problems: If troubleshooting the wiring and connections doesn’t resolve the issue, it’s best to consult an auto electrician.

- Brake System Repairs: Disassembling and repairing trailer brake components require specialized tools and expertise.

- Lack of Experience: If you’re uncomfortable working with electrical systems or trailer brakes, it’s always safer to seek professional help.

[warner brake module]

Conclusion

Warner Electric trailer brakes are essential for safe and reliable towing. By understanding the common problems, following proper diagnostic procedures, and performing regular maintenance, you can ensure your trailer brakes function optimally. Remember, safety should always be your top priority when towing. If you encounter persistent issues or are unsure about any aspect of trailer brake repair, it’s best to consult a qualified automotive technician.

FAQs

1. How often should I have my Warner Electric trailer brakes serviced?

It’s generally recommended to have your trailer brakes inspected annually or every 12,000 miles, whichever comes first.

2. Can I adjust Warner Electric trailer brakes myself?

Yes, but it requires some mechanical aptitude. If you’re comfortable working on your trailer, you can find adjustment instructions in your owner’s manual.

3. How long do Warner Electric trailer brakes typically last?

The lifespan varies depending on usage, maintenance, and driving conditions. With proper care, they can last for several years.

4. What does the gain setting on a Warner Electric brake controller do?

The gain setting controls the amount of braking power sent to the trailer brakes. Higher gain applies more braking force.

5. Can I use a different brand of brake controller with Warner Electric trailer brakes?

Yes, most electric brake controllers are compatible with Warner Electric trailer brakes as long as they meet the voltage and amperage requirements.