Warner electromagnetic brakes are a critical component of many vehicles, ensuring safe and efficient braking. When these systems malfunction, it can lead to safety concerns and costly repairs. This comprehensive guide will explore common issues with Warner electromagnetic brakes, their causes, and troubleshooting tips.

While remote diagnostics are becoming increasingly popular, physically inspecting the brake system is crucial for accurate diagnosis.

Common Problems with Warner Electromagnetic Brakes

Several issues can arise with Warner electromagnetic brakes, ranging from electrical faults to mechanical wear and tear. Here are some of the most common:

- Brake Drag: This occurs when the brakes remain partially engaged even when not applied, leading to reduced fuel efficiency, premature brake wear, and potential overheating. Common causes include a faulty brake release solenoid, worn brake shoes, or an improperly adjusted actuator.

- No Brakes: This dangerous situation arises when the brakes fail to engage when applied. Potential culprits include a blown fuse, a malfunctioning brake control module, a faulty brake pressure sensor, or a complete loss of power to the system.

- Intermittent Braking: This frustrating issue involves the brakes engaging and disengaging unexpectedly, leading to a jerky and unpredictable driving experience. The root cause could be a loose connection, a damaged wire harness, or a failing brake control unit.

- Excessive Noise: Unusual noises like grinding, squealing, or scraping during braking can indicate a problem with the Warner electromagnetic brake system. Worn brake shoes, a damaged brake drum, or a misaligned brake assembly are common culprits.

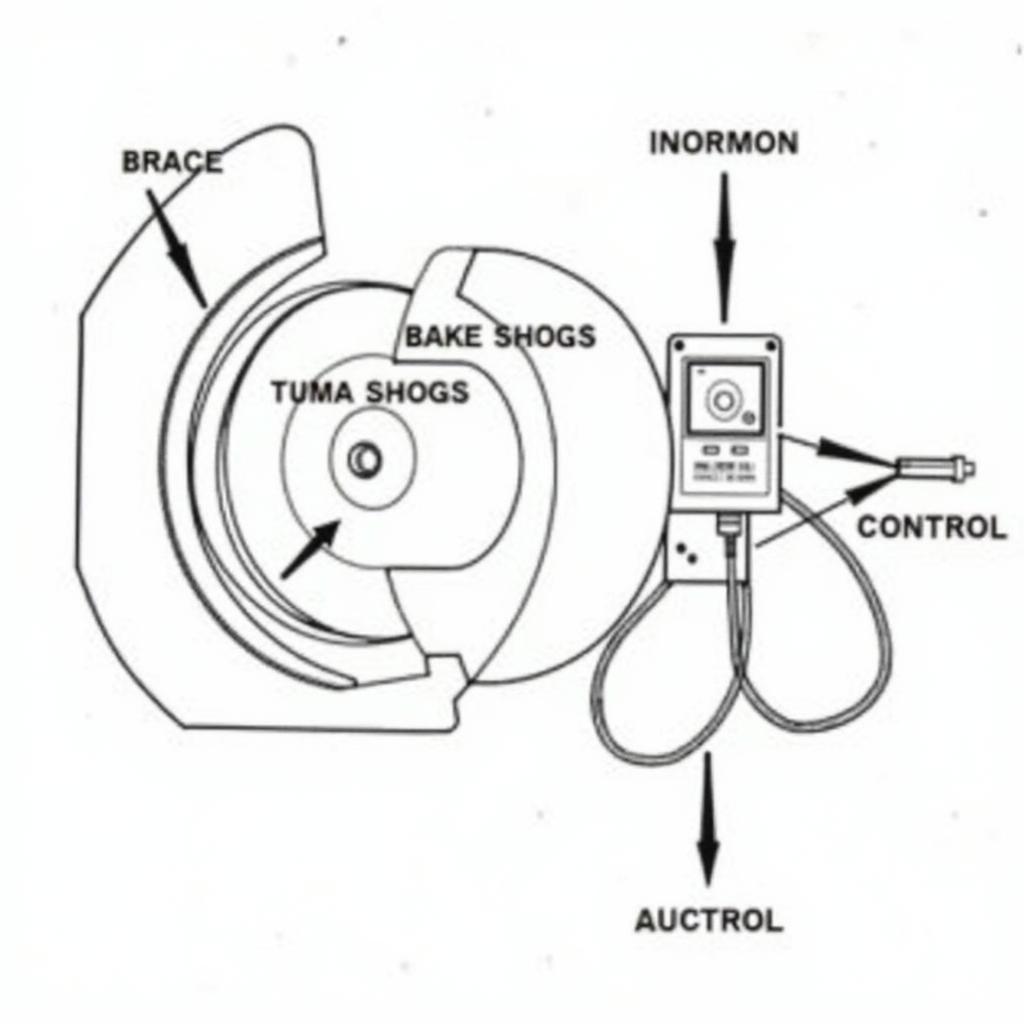

Warner Electromagnetic Brake System Components

Warner Electromagnetic Brake System Components

Diagnosing Warner Electromagnetic Brake Problems

Accurately diagnosing the root cause of a Warner electromagnetic brake issue requires a systematic approach:

- Visual Inspection: Begin by visually inspecting the brake system for any obvious signs of damage, such as worn brake shoes, damaged wiring, or loose connections.

- Check the Power Supply: Ensure the system receives adequate power and ground. Use a multimeter to check the voltage at the brake control module and other relevant components.

- Test the Actuator: The actuator plays a vital role in engaging and disengaging the brakes. Use a scan tool to command the actuator on and off, verifying its functionality.

- Inspect the Brake Shoes: Worn or damaged brake shoes can cause a variety of issues. If the brake shoes show significant wear, replace them.

- Diagnose the Control Module: A malfunctioning brake control module can lead to various problems. Use a scan tool to read diagnostic trouble codes (DTCs) and pinpoint the issue.

Seeking Professional Assistance

While some Warner electromagnetic brake problems can be diagnosed and repaired with basic tools and knowledge, it’s essential to consult a qualified technician for complex issues.

Here are some situations where seeking professional help is crucial:

- Safety Concerns: If you suspect a serious issue with your brakes, such as complete brake failure, it’s vital to have your vehicle towed to a qualified technician immediately.

- Lack of Expertise: Attempting to diagnose or repair complex electrical or electronic systems without proper training and equipment can be dangerous and could worsen the problem.

- Specialized Tools: Many diagnostic and repair procedures for Warner electromagnetic brakes require specialized tools that most vehicle owners do not possess.

Preventive Maintenance

Preventing brake problems is always preferable to dealing with them after they arise. Here are some preventive maintenance tips for Warner electromagnetic brakes:

- Regular Inspections: Regularly inspect your brakes for any signs of wear and tear, such as worn brake shoes, damaged wiring, or leaks.

- Timely Replacements: Replace brake shoes and other components at the manufacturer’s recommended intervals.

- Professional Servicing: Have your brakes serviced by a qualified technician at least once a year, or more frequently if you drive in challenging conditions.

Conclusion

Warner electromagnetic brakes are a crucial safety feature in many vehicles. Understanding how these brakes work, common problems, and basic troubleshooting steps can help you address issues promptly and ensure safe driving. However, remember to consult a qualified technician for any complex issues or if you’re unsure about performing the repairs yourself. For more information on specific Warner Electric brake models, you can explore the Warner electric brake em-180-20, Warner electric brake clutch co, and Warner electric brake parts pages on our website. We also have comprehensive resources available on Warner electric brakes and the Warner electric magnetic brake.