Warner elevator brakes are essential safety components that play a critical role in ensuring the safe operation of elevators. These brakes are designed to engage and hold the elevator car in place whenever power is lost or the elevator is at rest. However, like any other mechanical system, Warner elevator brakes can experience issues over time, leading to performance problems and safety concerns.

This comprehensive guide will delve into common problems associated with Warner elevator brakes, providing insights into their causes, symptoms, and potential solutions. We’ll also explore the importance of remote diagnostics, programming, and software installation in resolving these brake issues effectively.

Understanding Warner Elevator Brakes

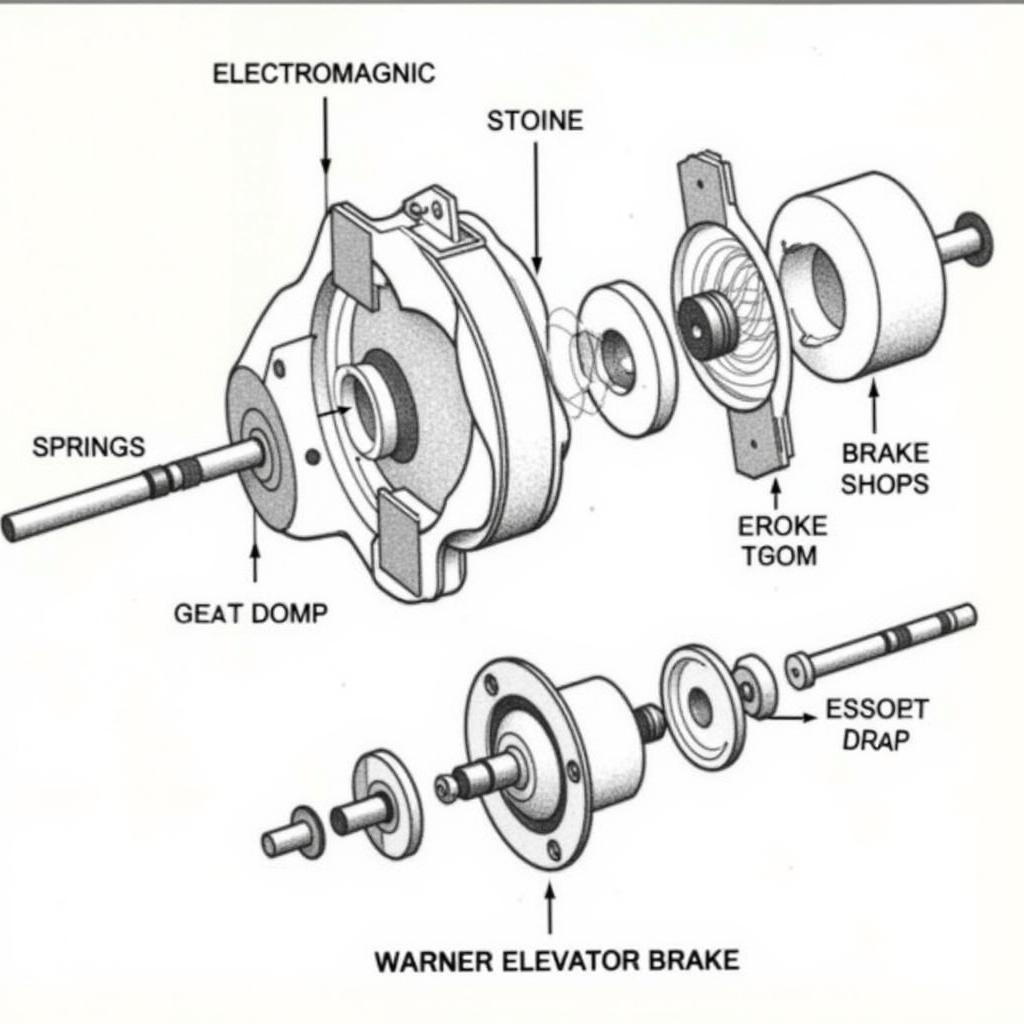

Before we jump into troubleshooting, it’s crucial to understand the basics of Warner elevator brakes. These brakes are typically electromagnetically released and spring-engaged, meaning they are held open by an electromagnet when the elevator is in operation. When the power is cut off or the elevator comes to a stop, the electromagnet de-energizes, allowing the springs to engage the brake and hold the elevator car securely.

Warner Elevator Brake Components

Warner Elevator Brake Components

Common Warner Elevator Brake Problems

Several issues can arise with Warner elevator brakes, often manifesting as unusual noises, jerky movements, or even complete brake failure. Here are some of the most common problems:

1. Worn Brake Shoes

Like the brakes in your car, elevator brake shoes are subject to wear and tear over time. As they wear down, their ability to grip the brake drum diminishes, leading to reduced braking power.

Symptoms:

- Squealing or grinding noises during braking

- Increased stopping distance

- Elevator drifting downwards when at rest

Solution:

Worn brake shoes require replacement. It is recommended to replace the shoes on both sides of the brake assembly simultaneously to ensure even wear and optimal performance.

2. Malfunctioning Electromagnet

The electromagnet is vital in releasing the brake and allowing the elevator to move. A malfunctioning electromagnet can prevent the brake from releasing or cause it to engage unexpectedly.

Symptoms:

- Elevator failing to move

- Brake not releasing after power is restored

- Intermittent elevator operation

Solution:

Troubleshooting the electromagnet involves checking its wiring, voltage supply, and coil resistance. A qualified technician may need to repair or replace the electromagnet.

3. Improperly Adjusted Brake

Correct brake adjustment is crucial for smooth and effective braking. An improperly adjusted brake can lead to uneven wear, excessive noise, and reduced braking efficiency.

Symptoms:

- Loud banging noises during braking

- Elevator jerking to a stop

- Premature brake wear

Solution:

Brake adjustment involves setting the correct clearance between the brake shoes and the drum. This procedure should only be performed by a trained elevator technician using specialized tools.

4. Defective Brake Spring

The brake springs provide the force necessary to engage the brake when the electromagnet is de-energized. A broken or weakened spring can compromise the entire braking system.

Symptoms:

- Elevator free-falling or dropping unexpectedly

- Brake failing to engage when power is off

- Visible damage to the brake spring

Solution:

Damaged or weakened brake springs require immediate replacement. This task should be carried out by a qualified technician who can ensure the new springs are correctly installed and tensioned.

The Role of Remote Diagnostics and Software

In today’s technologically advanced world, remote diagnostics, programming, and software installation are playing increasingly important roles in elevator maintenance and repair. These technologies allow technicians to:

- Remotely monitor brake performance: Sensors and data loggers can track brake performance in real time, transmitting information to a remote monitoring system. This enables early detection of potential problems before they escalate.

- Diagnose issues quickly and accurately: Remote diagnostic tools can connect to the elevator control system, providing detailed error codes and performance data. This helps technicians pinpoint the root cause of brake problems quickly.

- Implement software updates and adjustments: Software updates can enhance brake performance, improve safety features, and optimize energy efficiency. With remote access, technicians can install these updates without physically visiting the site.

Conclusion

Warner elevator brakes are essential safety devices that require regular inspection and maintenance. Understanding the common problems associated with these brakes, along with their symptoms and potential solutions, can help building owners and managers address issues promptly and prevent costly downtime or safety hazards.

Embracing remote diagnostics, programming, and software installation can significantly improve the efficiency and effectiveness of Warner elevator brake maintenance. By leveraging these technologies, elevator companies can ensure the long-term reliability and safety of their equipment while minimizing disruptions to building operations.

FAQs about Warner Elevator Brakes

1. How often should Warner elevator brakes be inspected?

Warner elevator brakes should be inspected by a qualified technician at least once a year. However, high-traffic elevators or those operating in demanding environments might require more frequent inspections.

2. Can I replace Warner elevator brake shoes myself?

Replacing elevator brake shoes is a complex procedure that requires specialized knowledge and tools. It is highly recommended to hire a qualified elevator technician for this task to ensure it is performed correctly and safely.

3. What is the typical lifespan of a Warner elevator brake?

The lifespan of a Warner elevator brake varies depending on usage, environmental conditions, and maintenance practices. With proper care and regular maintenance, these brakes can last for several years.

4. How can I tell if my elevator brake is malfunctioning?

Common signs of a malfunctioning elevator brake include unusual noises during braking (squealing, grinding, or banging), jerky movements, the elevator drifting downwards when at rest, or the elevator failing to move altogether.

5. What should I do if I suspect a problem with my elevator brake?

If you suspect an issue with your elevator brake, immediately contact a qualified elevator service company. Do not attempt to diagnose or repair the brake yourself, as this could be dangerous.