A malfunctioning Warner magnetic brake can bring your vehicle to a standstill, quite literally. Whether you’re experiencing a dragging brake, intermittent engagement, or complete failure, understanding the common issues and solutions is crucial. This comprehensive guide explores the intricacies of Warner magnetic brakes, equipping you with the knowledge to diagnose and potentially fix problems.

Understanding Warner Magnetic Brakes

Unlike conventional hydraulic brakes, Warner magnetic brakes utilize electromagnetism to generate braking force. They are commonly found in heavy-duty vehicles like trailers, RVs, and commercial trucks, providing reliable stopping power for demanding applications.

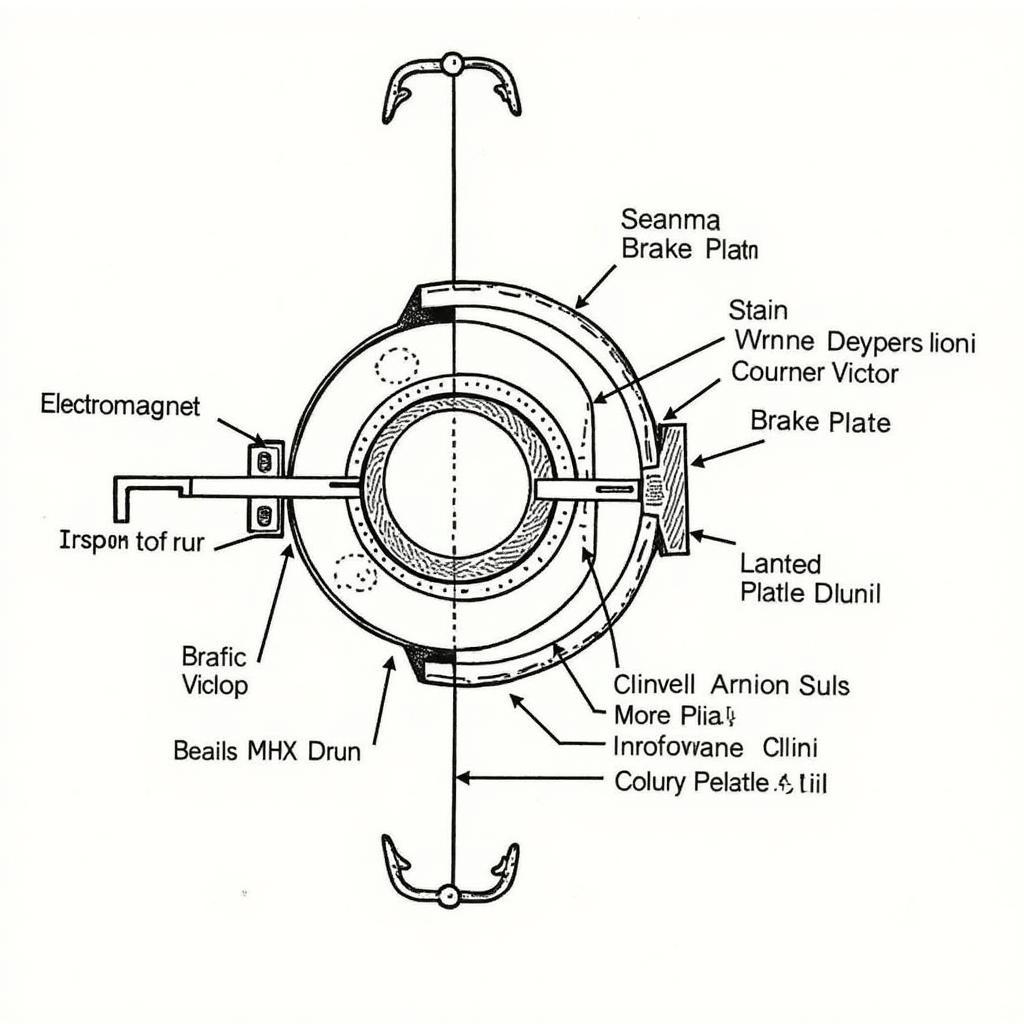

Here’s a simplified breakdown of their operation:

- Electromagnet: When you apply the brakes, an electric current flows through the electromagnet within the brake assembly.

- Magnetic Field: This current generates a strong magnetic field.

- Armature Plate: The magnetic field attracts an armature plate, which is connected to the brake shoes or pads.

- Friction and Braking: The armature plate’s movement forces the brake shoes or pads against the brake drum or rotor, creating friction and slowing down the vehicle.

Warner Magnetic Brake Components

Warner Magnetic Brake Components

Common Warner Magnetic Brake Problems and Solutions

While robust, Warner magnetic brakes aren’t immune to issues. Here are some common problems and their potential solutions:

1. Brake Drag

Symptoms: You feel resistance even when the brakes aren’t applied, leading to reduced fuel efficiency and premature wear.

Possible Causes:

- Residual Magnetism: The electromagnet may retain a small magnetic field even when deactivated, causing the armature plate to drag.

- Worn Brake Components: Worn brake shoes, drums, or bearings can create friction and mimic brake drag.

Solutions:

- Check for Residual Magnetism: A qualified technician can measure the magnetic field with a gauss meter to determine if residual magnetism is the culprit.

- Inspect Brake Components: Regularly inspect and replace worn brake shoes, drums, or bearings to ensure smooth operation.

2. Intermittent Braking

Symptoms: The brakes engage and disengage erratically, leading to unpredictable stopping distances and potentially dangerous situations.

Possible Causes:

- Electrical Issues: Loose or corroded wiring connections, a faulty brake controller, or a malfunctioning brake light switch can disrupt the flow of current to the electromagnet.

- Air Gap Issues: An incorrect air gap between the electromagnet and the armature plate can hinder proper engagement.

Solutions:

- Inspect Electrical System: Thoroughly check all wiring connections, the brake controller, and the brake light switch for any signs of damage or malfunction.

- Adjust Air Gap: Consult your Warner magnetic brake manual for the correct air gap specification and adjust accordingly.

3. Complete Brake Failure

Symptoms: The brakes fail to engage entirely, posing a serious safety risk.

Possible Causes:

- Loss of Power: A complete power loss to the brake system, often due to a blown fuse, a faulty relay, or a wiring issue, can render the brakes inoperable.

- Electromagnet Failure: A burnt-out electromagnet coil will prevent the generation of the magnetic field necessary for braking.

Solutions:

- Check Power Supply: Inspect the fuses, relays, and wiring harnesses for any signs of damage or disconnection.

- Test Electromagnet: A qualified technician can test the resistance of the electromagnet coil to determine its functionality.

Troubleshooting a Warner Magnetic Brake

Troubleshooting a Warner Magnetic Brake

When to Seek Professional Help

While this guide provides a starting point for troubleshooting, remember that working with automotive electrical systems can be hazardous. If you’re uncomfortable with any of the procedures mentioned or if the issue persists, it’s crucial to seek professional help.

A qualified automotive electrician specializing in trailer brakes can accurately diagnose the problem using specialized tools and equipment, ensuring a safe and effective repair. They can also advise on preventative maintenance to keep your Warner magnetic brake functioning optimally.

Tips for Maintaining Your Warner Magnetic Brake

Proactive maintenance can significantly extend the life of your Warner magnetic brake and prevent unexpected failures. Here are some essential tips:

- Regular Inspections: Regularly inspect your brake system for any signs of wear and tear, including frayed wires, loose connections, worn brake shoes, or damaged drums.

- Keep it Clean: Dirt, debris, and corrosion can impede the performance of your magnetic brake. Clean the brake assembly periodically using a suitable brake cleaner and a brush.

- Lubricate Moving Parts: Apply high-temperature brake grease to moving parts, such as the actuator arm and pivot points, to reduce friction and prevent premature wear.

- Professional Servicing: Schedule annual inspections and servicing by a qualified technician to ensure your brake system is in optimal condition.

FAQs: Warner Magnetic Brakes

What is the lifespan of a Warner magnetic brake?

The lifespan varies depending on usage, maintenance, and operating conditions. However, with proper care, they can last for several years.

Can I drive with a dragging Warner magnetic brake?

Driving with a dragging brake is not recommended as it reduces fuel efficiency, generates excessive heat, and can lead to premature wear and tear.

Can I convert my Warner magnetic brake to electric brakes?

Converting to electric brakes requires significant modifications to your trailer’s electrical system and axle assembly. It’s best to consult with a qualified trailer technician for such conversions.

What is the role of a break-away kit with a Warner magnetic brake?

A break-away kit is a crucial safety feature that activates the trailer brakes if it detaches from the towing vehicle. It ensures the trailer comes to a safe stop, preventing accidents.

Where can I find a reliable technician specializing in Warner magnetic brakes?

Contact your local trailer dealership, RV service center, or search online for certified automotive electricians specializing in trailer brake systems.

Conclusion

A properly functioning Warner magnetic brake is vital for safe and efficient towing. By understanding its operation, common problems, and maintenance tips, you can ensure your braking system remains reliable for miles to come. Remember, if you encounter any issues, don’t hesitate to seek professional assistance. Your safety and the safety of others on the road are paramount.