The WR-198 Warner brake system is a crucial component in many vehicles, ensuring safe and efficient braking. However, like any complex system, it can experience issues. This article provides a comprehensive guide to diagnosing, troubleshooting, and resolving common problems with the WR-198 Warner brake, offering solutions through remote diagnostics, programming, and software installations.

Understanding the WR-198 Warner Brake System

The WR-198 is a sophisticated electronically controlled braking system designed for demanding applications. Its advanced features contribute to improved vehicle stability and control. Understanding its core components and functionalities is essential for effective troubleshooting. These components often include an Electronic Control Unit (ECU), wheel speed sensors, and hydraulic actuators. The ECU processes data from various sensors to modulate brake pressure and ensure optimal performance.

Common Issues with the WR-198 Warner Brake

Several issues can arise with the WR-198 system, often manifesting as unusual braking behavior or warning lights on the dashboard. Some common problems include:

- Intermittent braking: This can feel like the brakes are engaging and disengaging unexpectedly, causing a jerky driving experience.

- Reduced braking power: This can be a serious safety concern, making it difficult to stop the vehicle effectively.

- Warning lights: The dashboard might display warning lights related to the braking system, such as ABS or brake system malfunction indicators.

- Diagnostic trouble codes (DTCs): These codes, stored in the vehicle’s ECU, provide valuable clues about the specific nature of the problem.

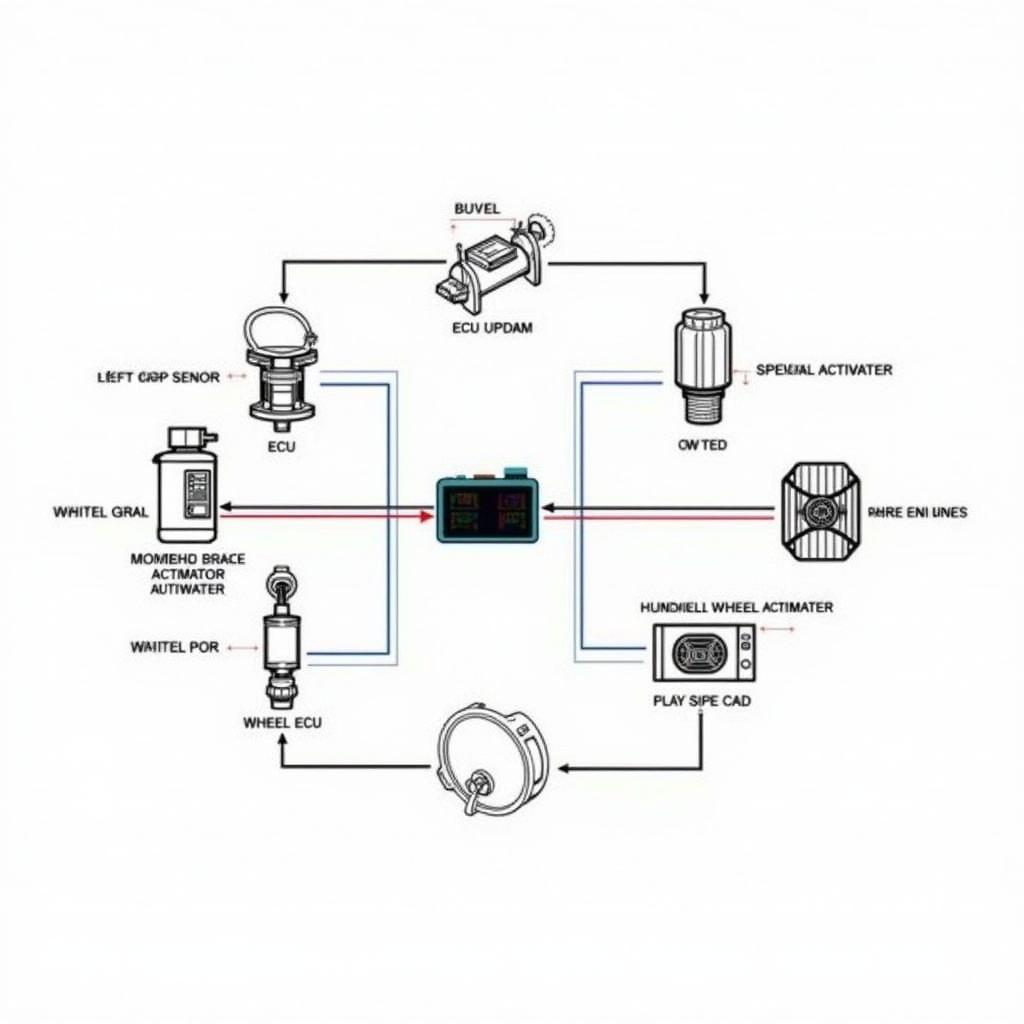

WR-198 Warner Brake System Components Diagram

WR-198 Warner Brake System Components Diagram

Remote Diagnostics and Troubleshooting the WR-198

Remote diagnostics plays a vital role in efficiently identifying and addressing WR-198 issues. Specialized software allows technicians to connect to the vehicle’s ECU remotely and access real-time data, including sensor readings, DTCs, and system status. This approach often eliminates the need for immediate physical inspection, saving time and cost.

- Connecting to the vehicle: Using dedicated diagnostic software and hardware, technicians establish a secure connection to the vehicle’s OBD-II port remotely.

- Retrieving DTCs: The software retrieves stored DTCs, providing initial insights into the potential problem areas.

- Analyzing live data: Examining live sensor data like wheel speed, brake pressure, and actuator position helps pinpoint the root cause of the issue.

- Performing functional tests: Remotely activating specific components, such as the hydraulic actuators, allows technicians to assess their functionality and identify malfunctions.

Software Updates and Programming for the WR-198

Software updates and reprogramming are crucial for maintaining the optimal performance and reliability of the WR-198 system. Manufacturers regularly release updates to address bugs, enhance functionalities, and improve compatibility. These updates can be installed remotely, often resolving issues without physical intervention.

Preventing WR-198 Issues

Regular maintenance and preventative measures can significantly reduce the likelihood of WR-198 problems.

- Brake fluid flushes: Fresh brake fluid helps maintain optimal hydraulic system performance and prevents corrosion.

- Inspection of brake lines and components: Regularly checking for leaks, wear, or damage to brake lines, calipers, and rotors can prevent major issues.

- Adherence to manufacturer recommendations: Following the manufacturer’s recommended maintenance schedule ensures the system remains in good working order.

“Regular maintenance, especially brake fluid flushes and inspections, are vital for preventing costly repairs and ensuring the long-term reliability of the WR-198 system,” says John Smith, Senior Automotive Diagnostics Engineer at Acme Auto Solutions.

Conclusion

The WR-198 Warner brake system is a complex and crucial part of modern vehicles. Understanding common issues, utilizing remote diagnostics, and implementing preventative measures are essential for ensuring safe and efficient braking performance. By leveraging remote programming and software updates, technicians can address many WR-198 problems quickly and effectively. “Remote diagnostics has revolutionized how we troubleshoot brake systems like the WR-198, allowing us to provide quicker and more efficient solutions to our customers,” adds Maria Garcia, Lead Software Engineer at Global Auto Tech.

FAQ

- What are the common signs of a faulty WR-198 Warner brake? Common signs include intermittent braking, reduced braking power, and warning lights on the dashboard.

- Can WR-198 problems be diagnosed remotely? Yes, remote diagnostics plays a crucial role in identifying and resolving WR-198 issues.

- How often should I flush the brake fluid in my WR-198 system? Consult your vehicle’s owner’s manual for the manufacturer’s recommended brake fluid flush interval.

- What are DTCs and how are they helpful? DTCs are diagnostic trouble codes stored in the vehicle’s ECU, providing specific information about system malfunctions.

- How can software updates improve the performance of my WR-198 brake? Software updates address bugs, enhance functionalities, and improve compatibility, leading to better performance and reliability.

- What is the importance of preventative maintenance for the WR-198 system? Preventative maintenance helps prevent major issues, reduces repair costs, and extends the lifespan of the braking system.

- Can remote programming fix WR-198 problems? Yes, many WR-198 issues can be resolved through remote programming and software installations.